Intermediate steel truss-concrete composite continuous steel bridge

A medium-supporting steel and concrete technology, applied in the field of bridge engineering, can solve the problems of increasing structural complexity, construction difficulty, and large building height, and achieve long-term structural performance reliability, reducing self-weight, pier and foundation structure size and The effect of reducing the requirement of foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

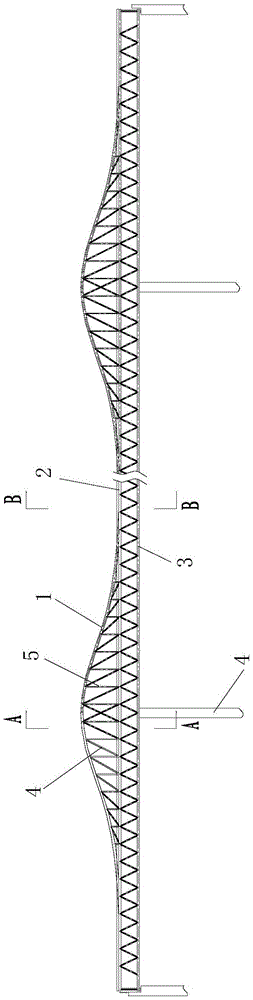

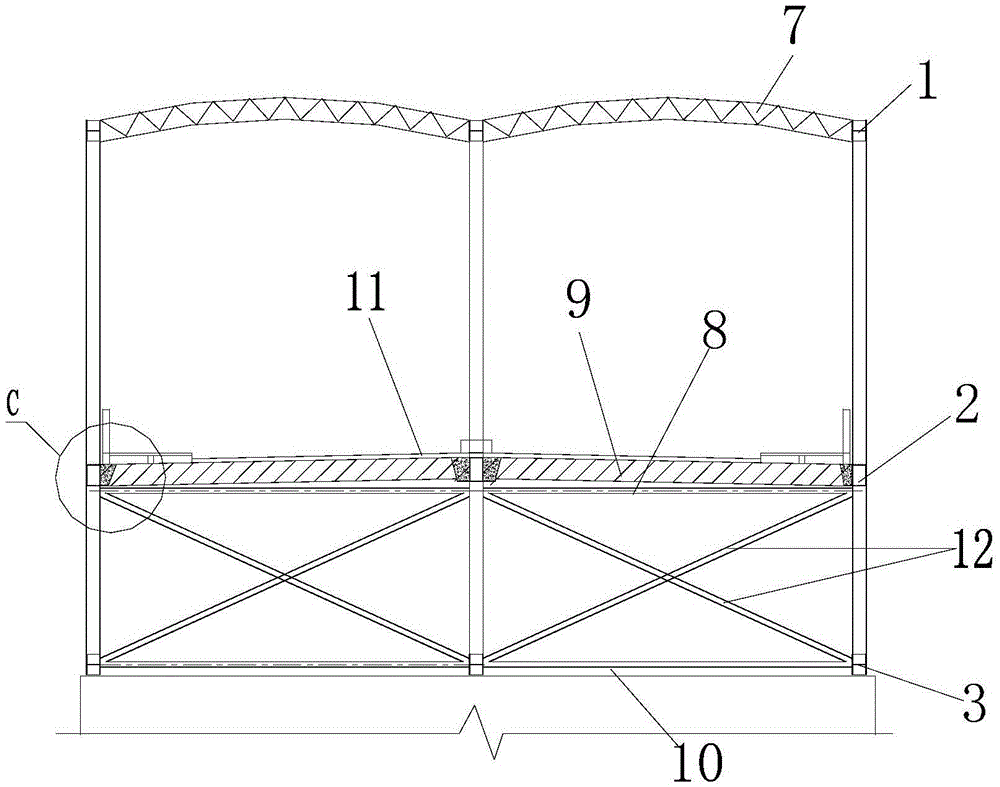

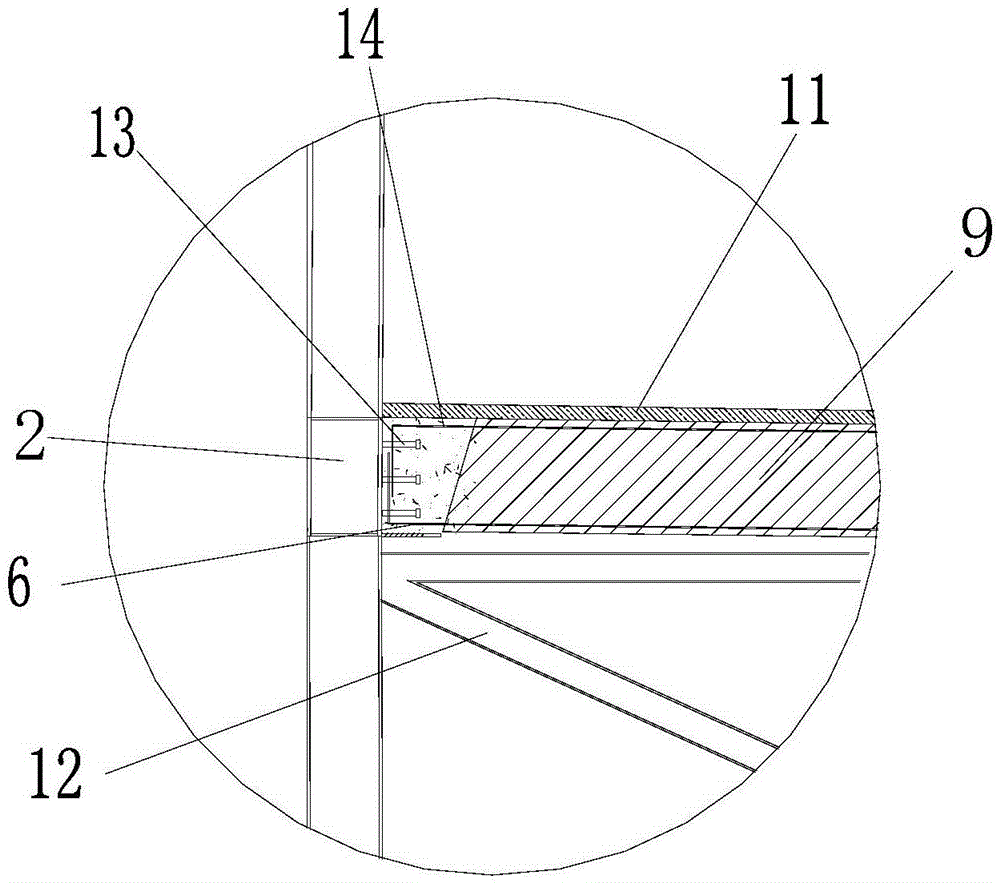

[0024] figure 1 It is a schematic diagram of the bridge structure of the present invention, figure 2 for figure 1 Sectional view along A-A direction, image 3 for figure 2 Enlarged view at C, Figure 4 for figure 1 The sectional view along B-B direction, as shown in the figure, the mid-supporting steel truss-concrete composite continuous steel bridge of this embodiment includes a main truss girder, and the main truss girder is composed of at least two steel truss girders arranged in parallel longitudinally, Steel truss beams are equipped with upper chord 1, middle chord 2 and lower chord 3;

[0025] The upper chord 1 and the middle chord 2 and between the middle chord 2 and the lower chord 3 are respectively connected through their respective webs, and the concrete bridge slab 9 is fixed between the middle chords 2 of adjacent steel truss girders to form a steel truss bridge. Box-concrete composite structure, the concrete bridge slab 9 is a cast-in-place formed concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com