Gear type diesel engine

A diesel engine, gear type technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of high noise, difficult processing, and difficult processing, and achieve the effect of stable operation and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

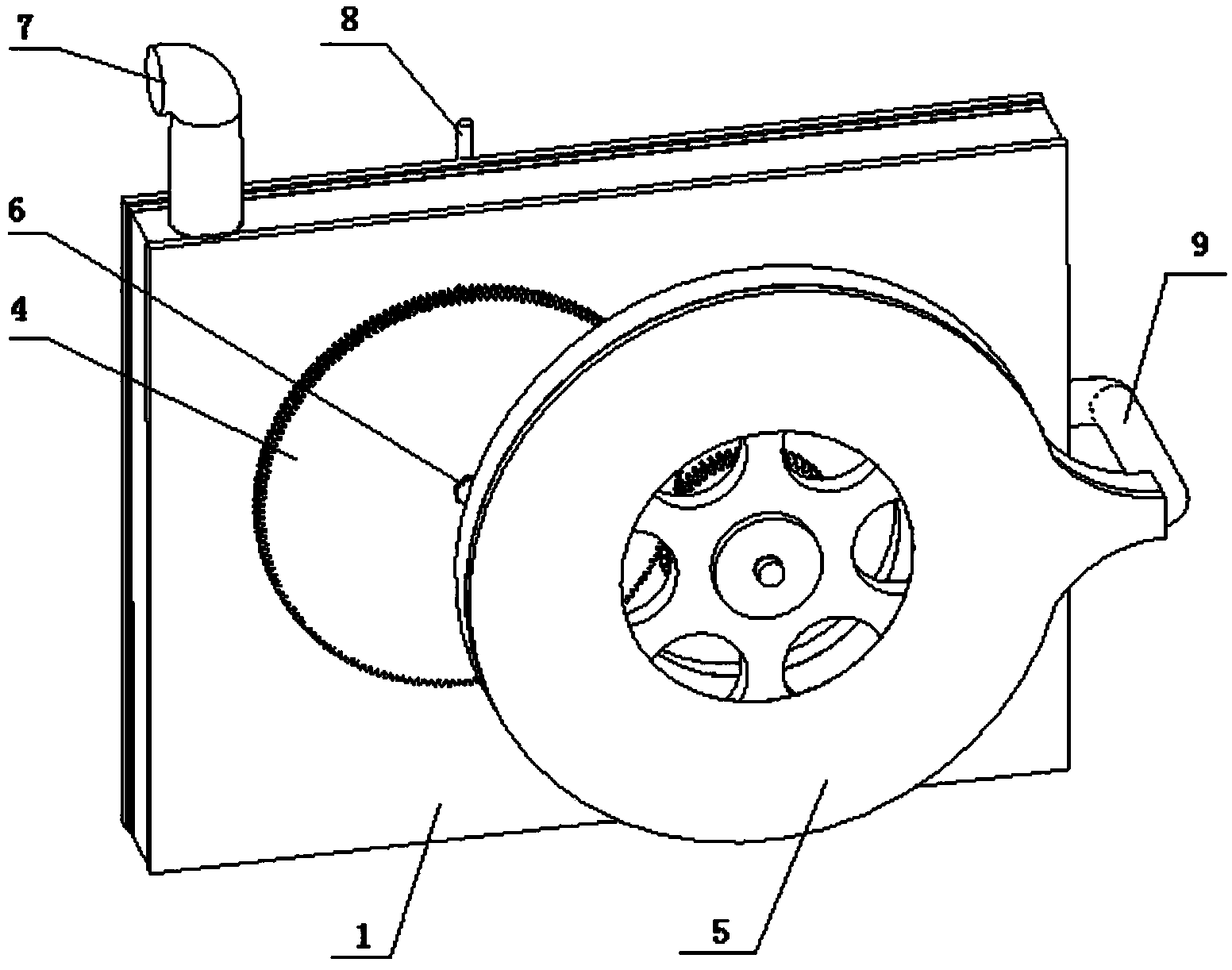

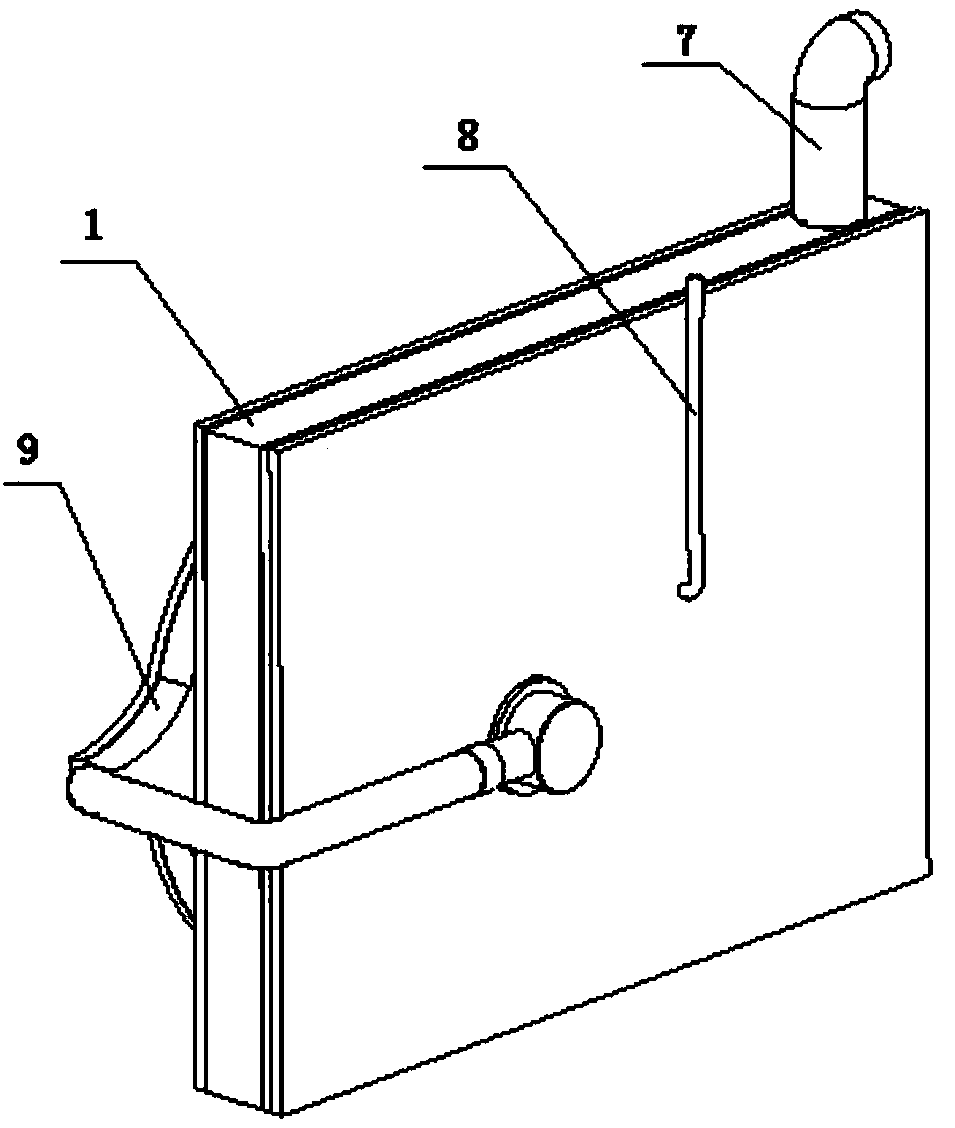

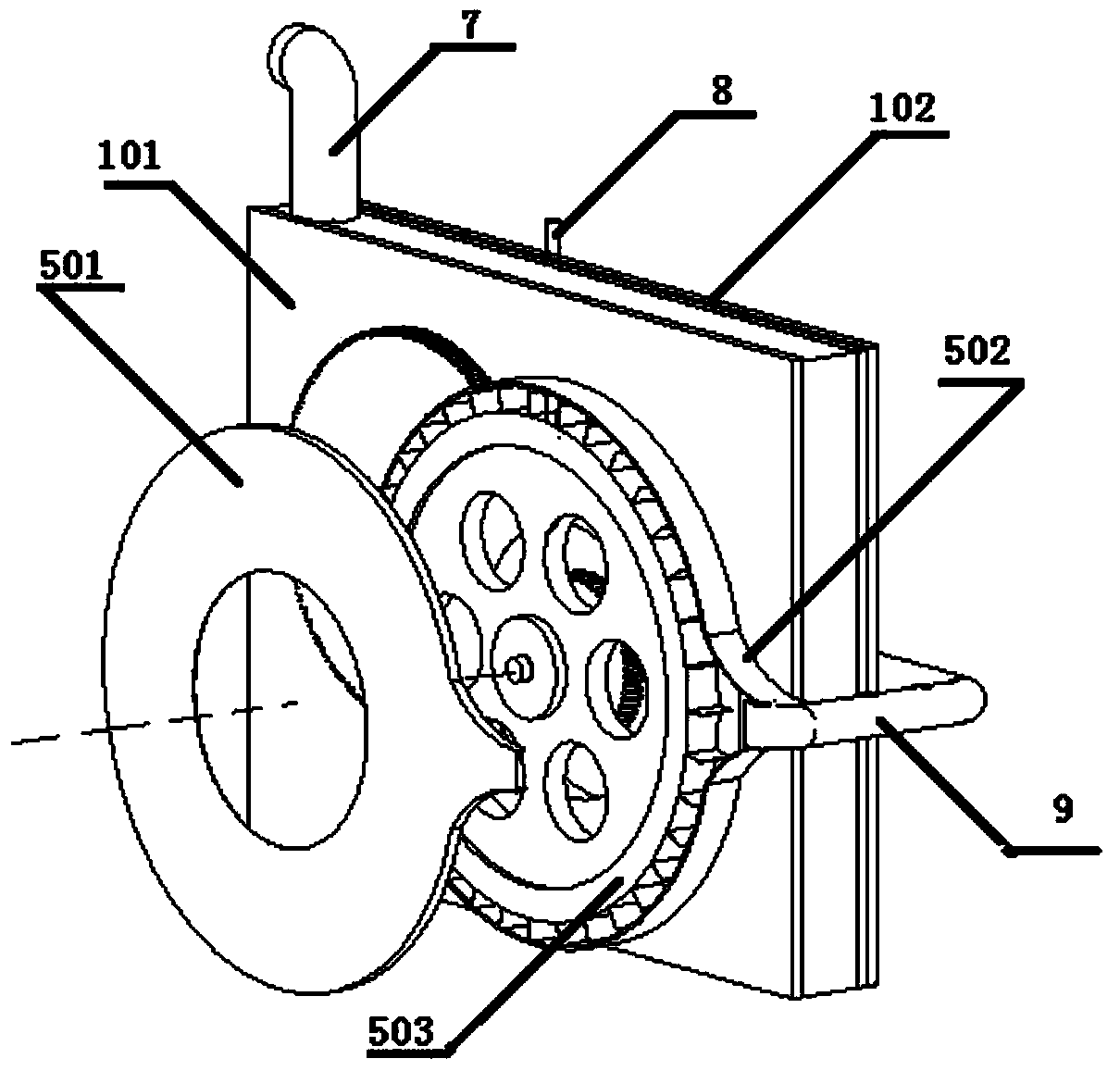

[0050] A gear type diesel engine includes an engine box 1, a rotor type piston ball 2, a rotor type cylinder 3 located in the engine box 1, a transmission gear set 4 located outside the engine box 1, a gas booster device 5, wherein the rotor type piston The ball 2 and the rotor type cylinder 3 mesh with each other. The rotor type piston ball 2 and the rotor type cylinder 3 are respectively installed in the engine box 1 through a gear shaft 6, and one end of the two gear shafts 6 also extends out of the engine box 1 respectively. Connected to the transmission gear set 4; the gas boosting device 5 is installed on the outside of the engine box 1; the engine box 1 is also respectively installed with a gas exhaust pipe 7 and a fuel delivery pipe 8 connected to the rotor cylinder 4 , Air inlet pipe 9, wherein the inlet end of the air inlet pipe 9 is connected to the gas boosting device 5.

[0051] The engine box 1 is formed by connecting an engine box A101 and an engine box B102. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com