Construction machine

A technology for construction machinery and engines, applied in mechanical equipment, engine control, machines/engines, etc., can solve the problems that may occur even when the target speed is increased, and the actuator action cannot be substantially performed, and achieve rapid rise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

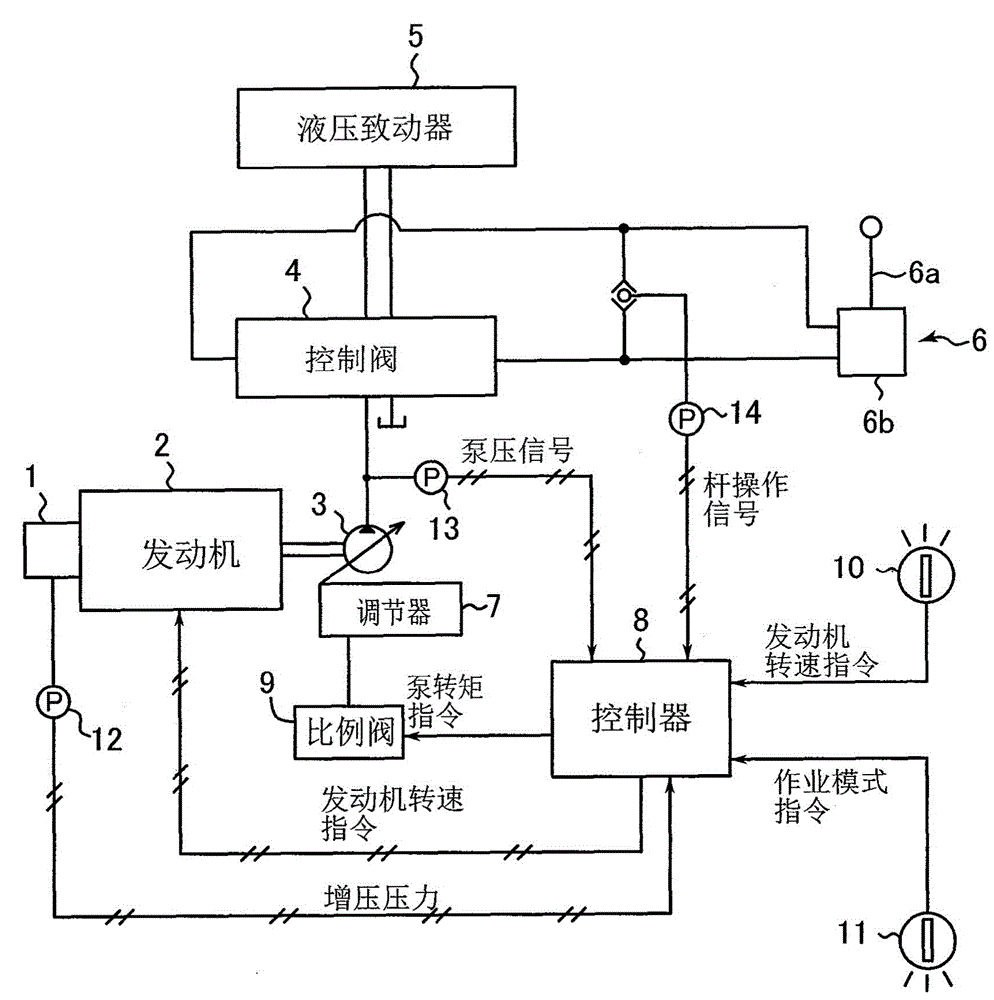

[0013] figure 1 Main components of the construction machine according to the embodiment of the present invention are shown. This construction machine is equipped with: an engine 2 equipped with a supercharger (turbocharger) 1; a hydraulic pump 3 driven by the engine 2 to eject working oil; a hydraulic actuator 5 The control valve 4 switches the state of supplying hydraulic oil from the hydraulic pump 3 to the hydraulic actuator 5 ; the remote control valve 6 is operated to switch the control valve 4 ; and the controller 8 . The remote control valve 6 includes: an operating rod 6a; and a valve main body 6b that outputs a pilot pressure for operating the control valve 4 based on the operation of the operating rod 6a.

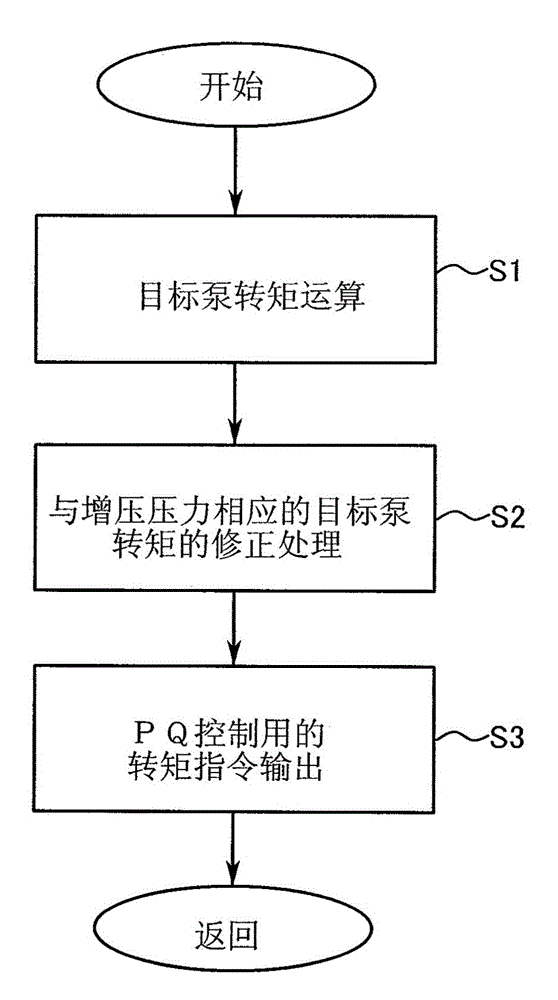

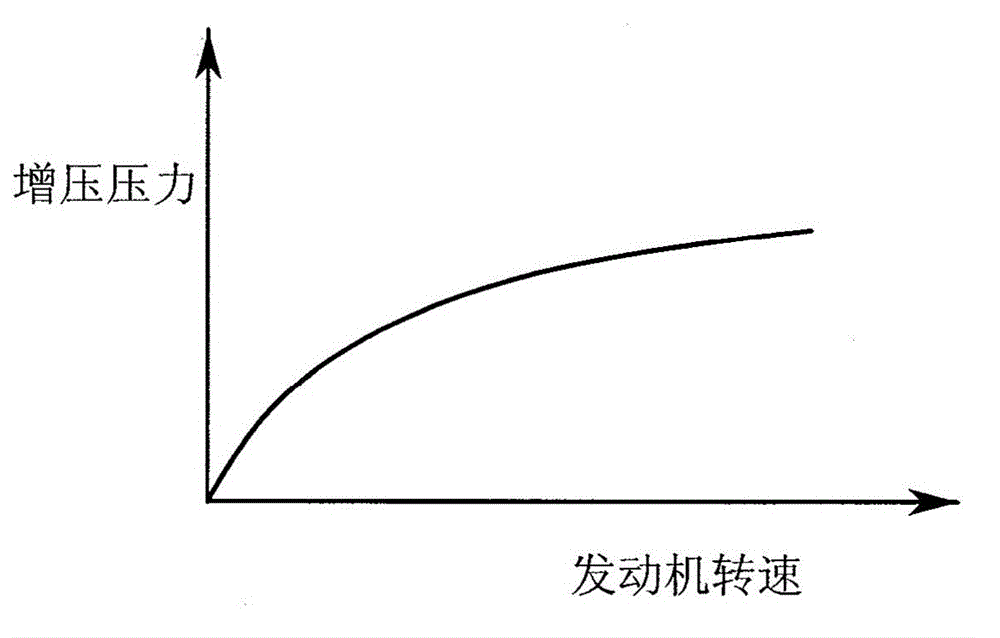

[0014] The hydraulic pump 3 is a variable displacement hydraulic pump, and its tilting is controlled by the controller 8 via a regulator 7 and a proportional valve 9 . The controller 8 inputs a pump torque command (tilt command) to the proportional valve 9 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com