Blade vibration damping control method and system of wind generating set

A technology for wind turbines and control systems, which is applied in the control of wind turbines, wind turbines, and wind power generation, and can solve problems such as high loads, large response time delays, and large torques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

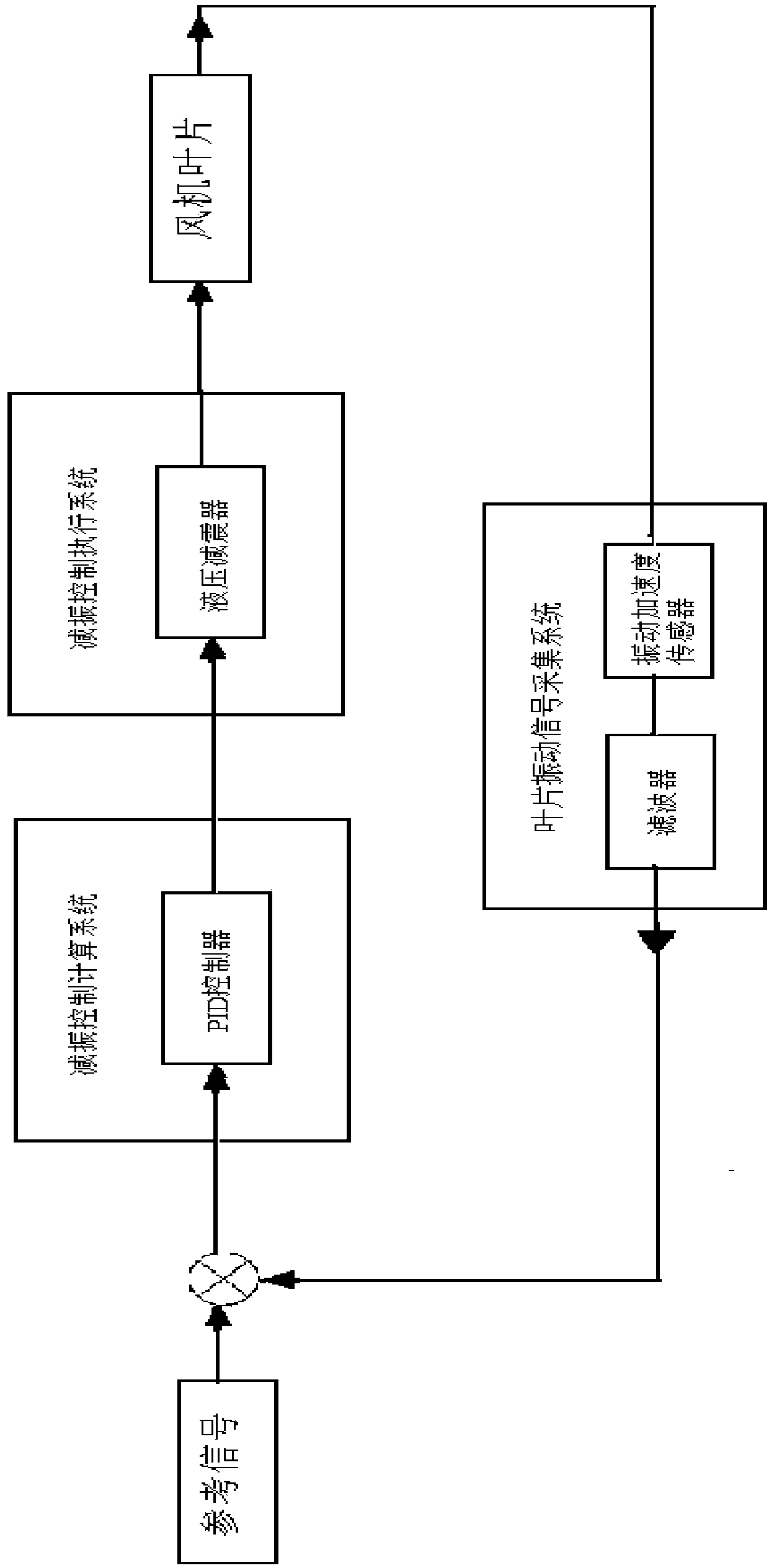

Image

Examples

Embodiment Construction

[0024] The main steps of the method for controlling blade vibration reduction of a wind power generating set in the present invention include presetting the reference value of the vibration acceleration of the blade, collecting the measurement value of the vibration acceleration of the blade, comparing the measurement value with the reference value, and controlling the vibration reduction of the blade according to the comparison result. .

[0025] Among them, the unit of blade vibration acceleration is m / s 2 , which can be used to measure the amplitude and other properties of the blade vibration. When the blade is in a non-vibrating state, the vibration acceleration of the blade is 0. In the present invention, it is necessary to perform feedback closed-loop control on the measured blade vibration acceleration value, so its reference value is set to 0.

[0026] More specifically, the measured value of the blade vibration acceleration used in the present invention is first fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com