Service life prediction method based on binocular vision monitoring and surface crack image recognition

A technology for image recognition and surface cracks, which is applied in image analysis, image data processing, and measurement devices, can solve the problems of cumbersome implementation and low practicability of monocular visual monitoring of the fatigue state of the target surface, and achieve a wide range of applications and improve measurement The effect of high accuracy, efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

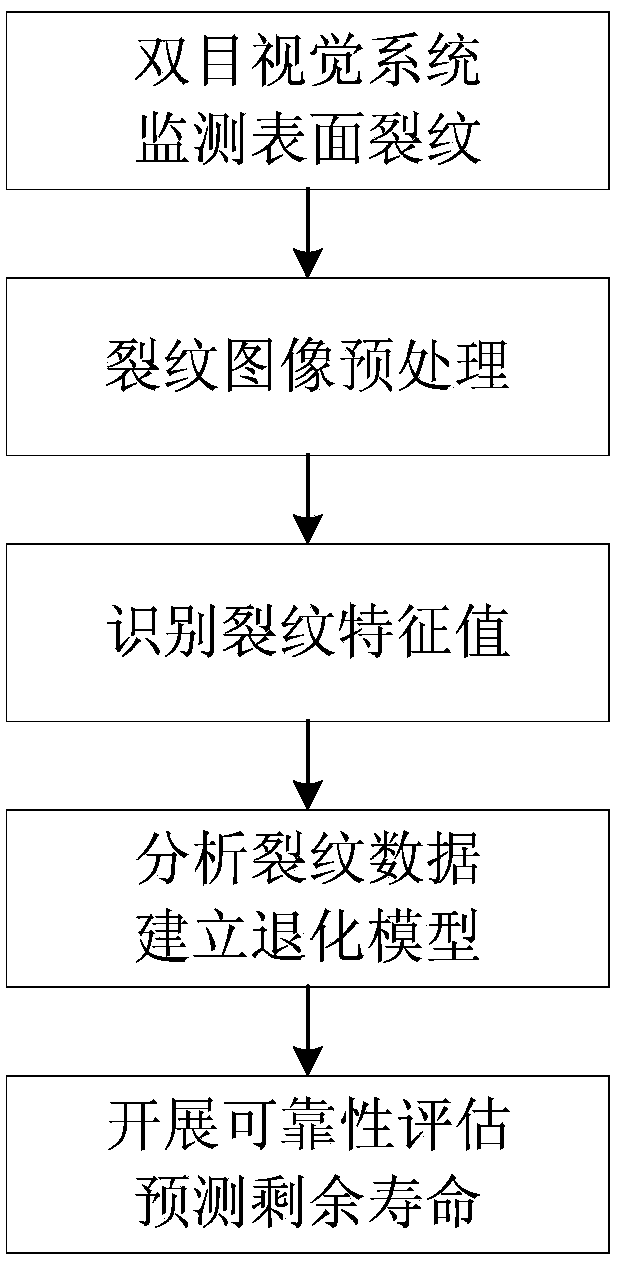

[0034] The operation process of the life prediction method based on binocular vision monitoring and surface crack image recognition is as follows: figure 1 As shown, the method of the present invention will be described in detail below with reference to the embodiments.

[0035] Step 1, complete the calibration of the internal and external parameters of the binocular vision system.

[0036] (1) Fix the relative positions of the left and right cameras in the binocular system, place the binocular cameras to be calibrated in different positions, and simultaneously shoot the 2D checkerboard target at different angles, shoot 30 pictures, and use TOOLBOX_calib in MATLAB to calibrate The toolbox completes the calibration of the internal parameters of the left and right cameras.

[0037] (2) Use the left and right cameras in the binocular system to take a picture of the target fixed at the same position, and complete the calibration of the external parameters of the left and right ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com