Processing technique for speaker frame with a plurality of blanks

A technology of speaker basin frame and processing technology, applied in the direction of sensors, electrical components, etc., can solve the problems of low dimensional control accuracy and high defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

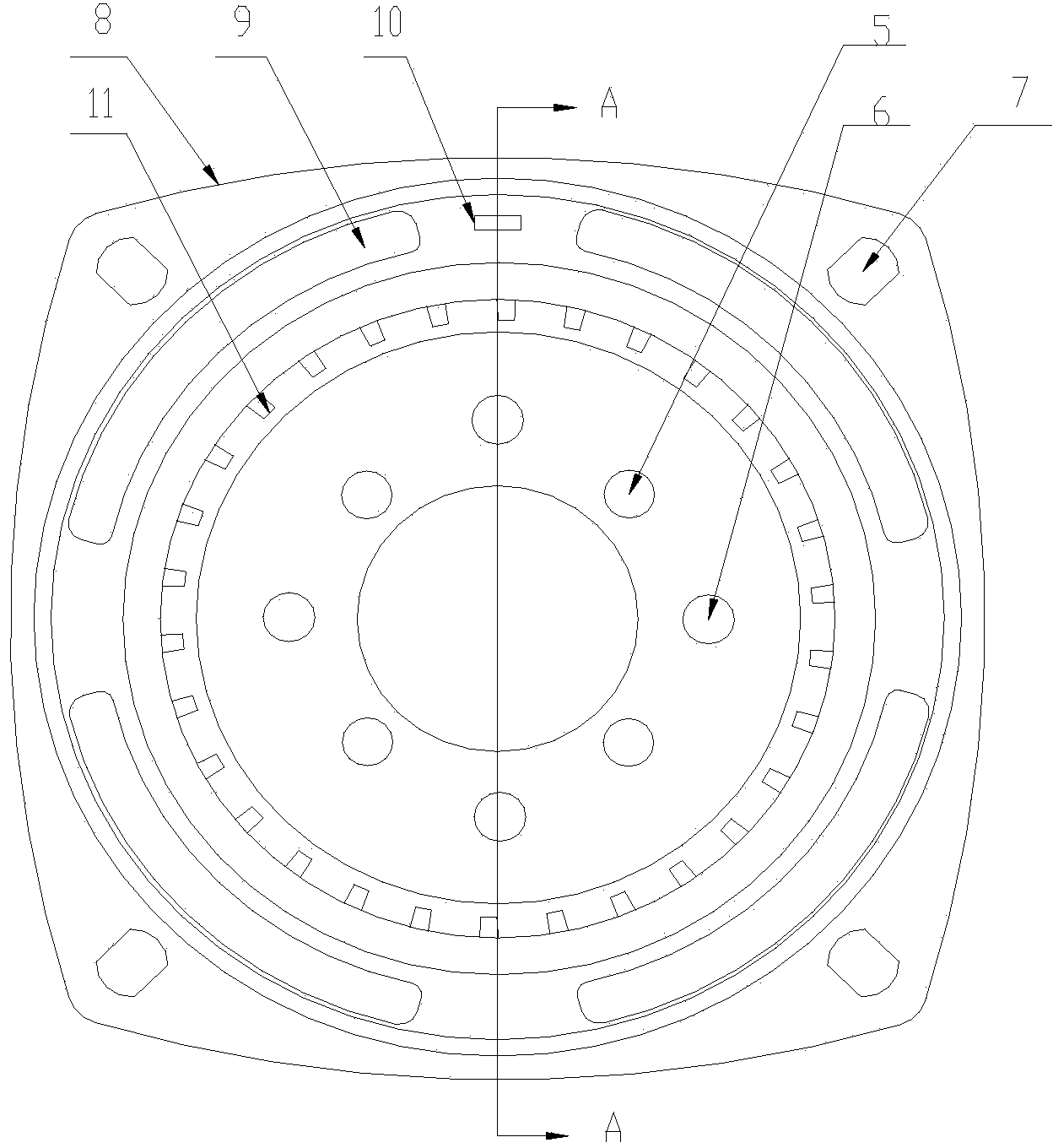

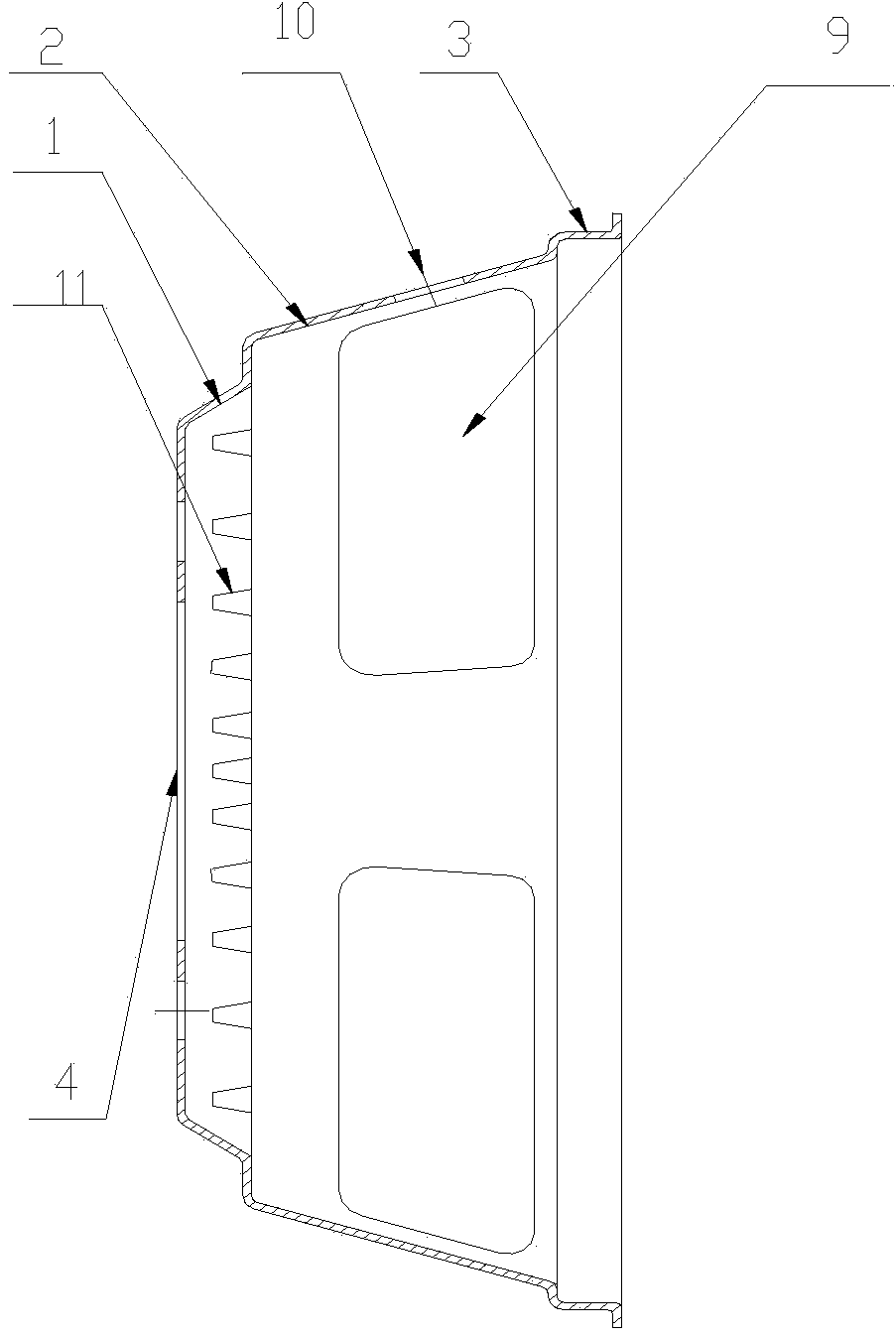

[0019] like figure 1 and figure 2 Shown, a kind of processing technology of the loudspeaker basin frame with multiple blanks, comprises the following steps:

[0020] Step 1: cut the material, cut out a width of 104 mm on a cold-rolled carbon steel sheet with a thickness of 0.5 mm by a shearing machine, and be long 1250 mm of coil material;

[0021] Step 2: blanking stretching, punching out a circular raw material with a diameter of 103 mm on the coiled material through the blanking stretching die; and stretching the circular raw material into a bowl-shaped semi-finished product. The inner diameter of the bowl-shaped semi-finished product increases successively from bottom to top, and the described bowl-shaped semi-finished product is composed of three steps from bottom to top, and the three steps include a first step with a height of 4.5 mm. The second step 2 with a height of 17.5 mm and the third step 3 with a height of 3 mm;

[0022] Step 3: punching and trimming, punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com