Fiber optic magnetic flux sensor for application in high voltage generator stator bars

A magnetic flux sensor and sensor technology, applied in the direction of measuring magnetic variables, instruments, electromechanical devices, etc., can solve problems affecting reflection properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following discussion of embodiments of the invention relating to MBG sensors for measuring the force acting on a stator bar of a high voltage generator is merely exemplary in nature and is not intended to limit the invention or its application or use in any way. The radial component of the magnetic flux on .

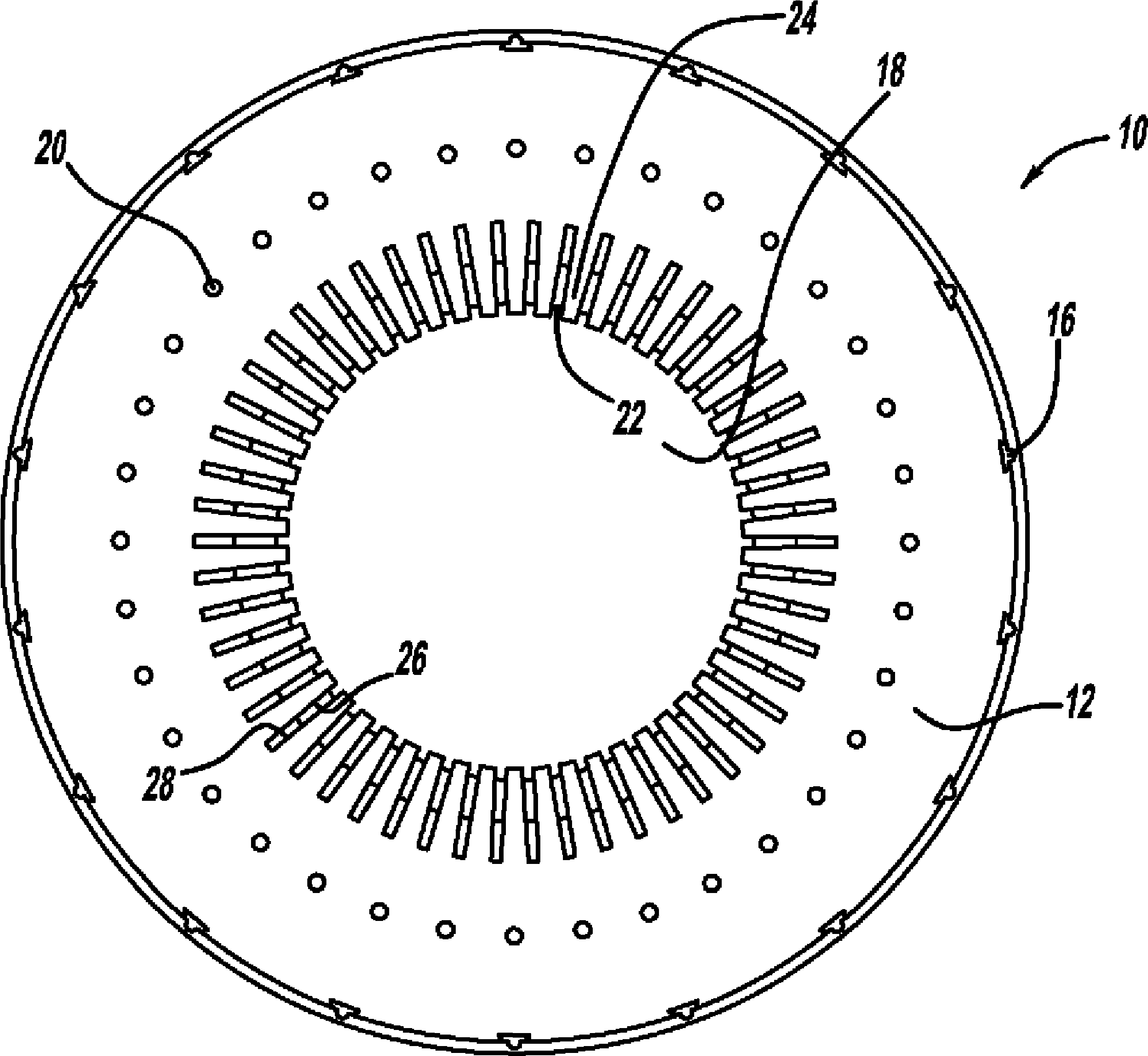

[0017] figure 1 is a cutaway perspective view of a stator core 10 of a high voltage generator and figure 2 is a sectional view of the stator core 10 . The stator core 10 includes a magnetic cylindrical portion 12 formed from an assembly of stacked thin iron lamination segments aligned by key bars 16 and defining an inner bore 18 . A series of through bolts 20 extend through the lamination segments to compress and hold the segments to form the cylindrical portion 12 . The lamination segments of the cylindrical portion 12 define a series of circumferentially positioned slots 22 that open to the bore 18 and define stator core teeth 24 therebetween. Electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com