Miniature hydraulic granulated feed machine

A hydraulic feed machine technology, applied in feed, food forming, food science, etc., can solve problems such as difficulty in adjustment and elimination, unsuitability for feed processing, complex structure, etc., to achieve simple structure, small machine size, The effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

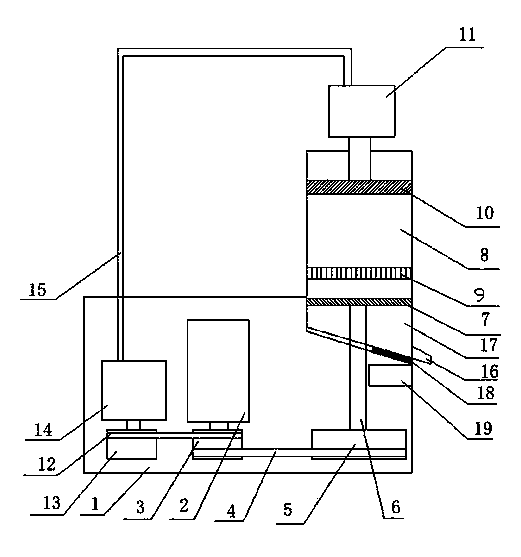

[0013] like figure 1 A kind of micro-hydraulic pellet feed machine of the present invention as shown, comprises frame 1, and described frame one end is provided with powder material collecting groove 19, and described powder material collecting groove 19 top is provided with cutting cavity 17, and described cutting cavity 17 is provided with a material chamber 8 at the top, and a hydraulic device 11 is provided at the top of the material chamber 8, and a motor 2 is provided on the frame 1, and the motor 2 is connected to the motor pulley 3, and the motor pulley 3 is connected to the cutting machine through the belt 4. Pulley 5, the cutting pulley 5 is placed on one end of the cutter head shaft 6, the other end of the cutter head shaft 6 is provided with a cutter head 7, and an orifice 9 is arranged above the cutter head 7, and the orifice plate 9 is placed on the material Cavity 8 bottom. The material cavity 8 is provided with a pressing plate 10, the pressing plate 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com