Secondary Cooling Method for Controlling Transverse Cracks in Corner of Microalloyed Steel Slabs

A technology of secondary cooling and micro-alloyed steel, which is applied in the field of continuous casting, can solve the problems of difficult realization of continuous casting machines, reduce crack sensitivity, reduce the probability of transverse cracks at the corners of billets, and reduce stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

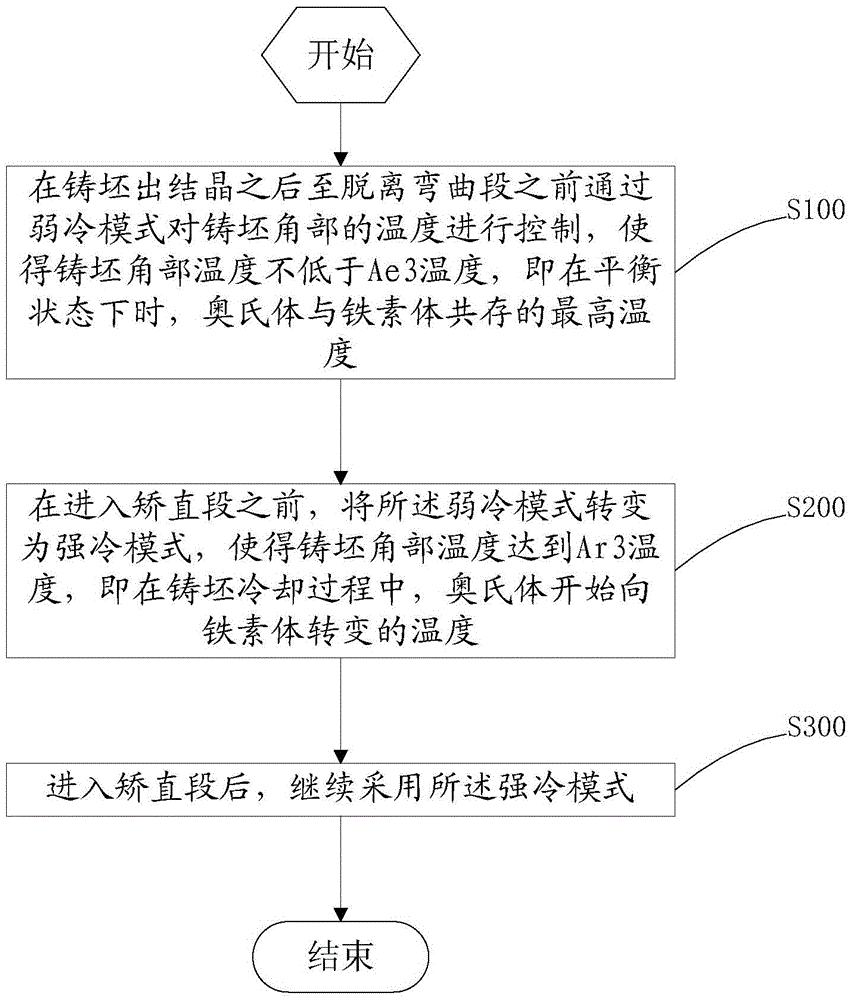

[0019] Such as figure 1 as shown, figure 1 It is a schematic flowchart of a secondary cooling method for controlling transverse cracks at corners of microalloyed steel slabs provided by Embodiment 1 of the present invention.

[0020] Step S100: Control the temperature of the corner of the slab through the weak cooling mode after the slab crystallizes and before it leaves the bending section, so that the temperature of the corner of the slab is not lower than the Ae3 temperature, that is, in the equilibrium state, the austenite The highest temperature that coexists with ferrite. In this embodiment, temperature control is performed on the corners of the slab after crystallization and before leaving the bending section, so that the temperature of the corners of the slab can be obtained at a lower cooling rate under the action of the weak cooling mode. Precipitates with larger size and more diffuse distribution. Among them, the Ae3 temperature needs to be obtained according to ...

Embodiment approach 2

[0028]When a steel factory was casting a 230mm slab, severe corner transverse cracks occurred on both the inner and outer arcs of the slab. The steel type used was Q345X, the cross-sectional size was 1500mm×230mm, and the casting speed was 1.3m / min. The scheme of the present invention is used to reset the secondary cooling model, and the secondary cooling model is set as follows: during the time period after the slab is crystallized and before it leaves the bending section, the specific water volume is set to 0.28L / kg until the slab is cooled The highest temperature at which austenite and ferrite coexist in an equilibrium state. It can be understood that the highest temperature at which austenite and ferrite coexist needs to be tested to obtain an accurate value for the steel used in the steel plant. And then increase the specific water amount to 1.2L / kg during the period of time reaching the end of the straightening section until the slab cools down to the temperature at whic...

Embodiment approach 3

[0031] When a steel factory was casting a 230mm slab, severe corner transverse cracks occurred on both the inner and outer arcs of the slab. The steel used was Q345R-1, the cross-sectional size was 2050mm×230mm, and the casting speed was 1.0m / min. The scheme of the present invention is used to reset the secondary cooling model, and the secondary cooling model is set as follows: during the time period after the slab is crystallized and before it leaves the bending section, the specific water volume is set to 0.24L / kg until the slab is cooled The highest temperature at which austenite and ferrite coexist in an equilibrium state. It can be understood that the highest temperature at which austenite and ferrite coexist needs to be tested to obtain an accurate value for the steel used in the steel plant. And then increase the specific water amount to 0.8L / kg during the period of time reaching the end of the straightening section, until the slab is cooled to the temperature at which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com