Color-coated steel composite board, manufacturing method of color-coated steel composite board, and color-coated steel sandwich board comprising color-coated steel composite board

A composite panel and sandwich panel technology, which is applied in the field of color steel sandwich panels, can solve the problems of poor impact resistance of color steel plates, achieve good performance, improve impact resistance, and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

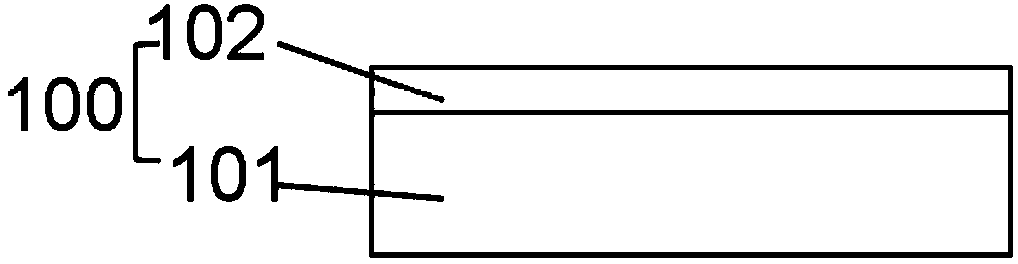

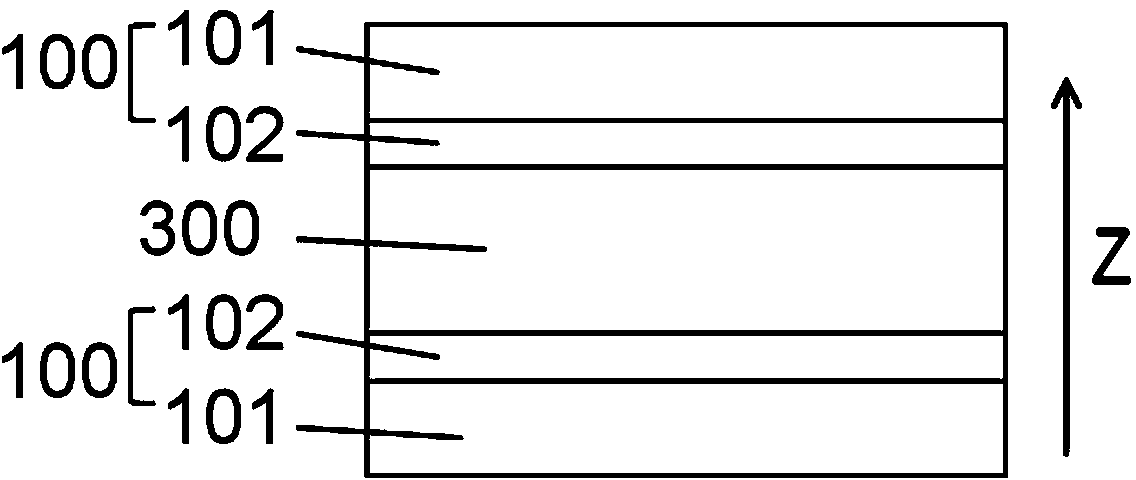

[0034]In addition, the present invention also provides a method for preparing a color steel composite board, which includes the following steps: S1, providing a metal substrate; S2, forming a resin containing a resin base material and reinforcing fibers on one side surface of the metal substrate composite layer to obtain the color steel composite board. The color steel composite plate prepared by the above method can form a layer of resin composite layer on the upper surface of the metal substrate. This layer of resin composite layer can improve the impact resistance of the metal substrate, so that the color steel composite board also has higher impact resistance as a whole. At the same time, the resin composite layer has high toughness and can also improve the bending strength of the color steel composite board. In addition, the reinforcing fiber can also play a reinforcing role, so that the color steel composite panel has better performance.

[0035] According to the above...

Embodiment 1

[0060] After impregnating the glass fiber in a phenolic resin glue solution with a viscosity of 500mpa·s, the impregnated fiber is obtained;

[0061] Lay the impregnated fibers on the metal substrate with a thickness of 2 mm according to the network arrangement, and after curing for 24 hours at a pressure of 0.05 MPa and a temperature of 100 ° C, a color steel composite board is obtained. Wherein, the mass ratio of phenolic resin and glass fiber in the resin composite layer is 50:10. The thickness of the resin composite layer is 0.8mm.

Embodiment 2

[0063] After impregnating the glass fiber in a phenolic resin glue solution with a viscosity of 500mpa·s, the impregnated fiber is obtained;

[0064] Lay the impregnated fibers on the metal substrate with a thickness of 2 mm according to the network arrangement, and after curing for 24 hours at a pressure of 0.05 MPa and a temperature of 100 ° C, a color steel composite board is obtained. Wherein, the mass ratio of phenolic resin and glass fiber in the resin composite layer is 50:20. The thickness of the resin composite layer is 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com