Dosing system

A technology of dosing system and dosing pool, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of small dosage, blockage of pipes, bursting of pipes, etc., and achieve the effect of not easy to block pipes and improve the efficiency of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

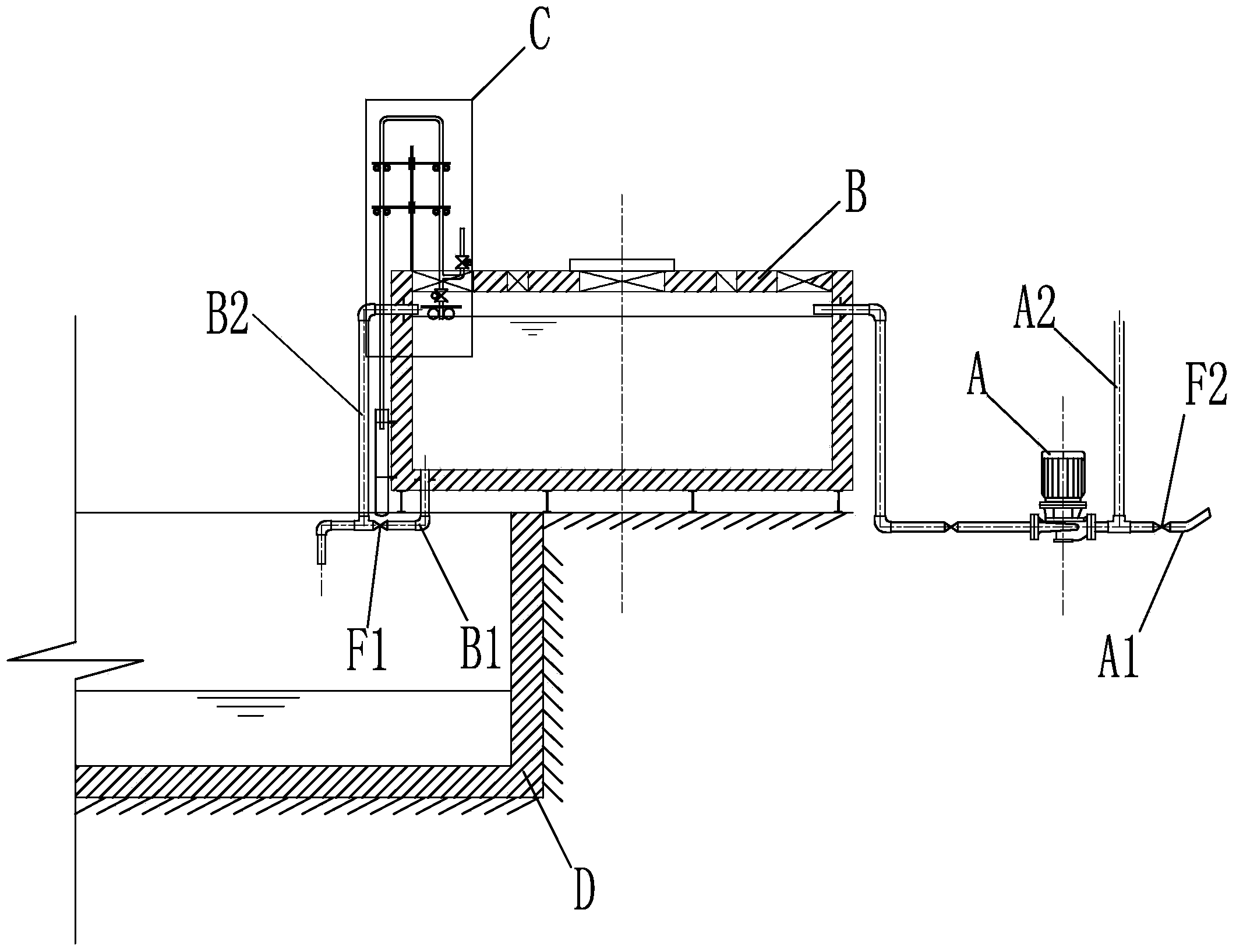

[0022] like figure 1 Shown: a dosing system consisting of a dosing pump A, a dosing pool B, a dosing device C and an aeration tank D, the entrance of the dosing pump A is connected with a dosing pipe A1, the dosing pump The outlet of A communicates with the dosing tank B through a pipe, and the dosing device C is fixed on the dosing tank B, and the dosing device C communicates with the dosing tank B and the aeration tank D.

[0023] The inlet of the dosing pump A is connected with a flushing pipe A2, the front section of the dosing pipe A1 is provided with a one-way valve F2, and the tail section of the dosing pipe A1 is bent obliquely upward. The bottom of the dosing pool B is provided with a venting pipe B1, the venting pipe B1 is provided with a valve F1, and the upper side wall of the dosing pool B is provided with an overflow pipe B2, and the venting pipe B1 and The overflow pipe B2 leads to the aeration tank D after meeting.

[0024] The dosing device C is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com