Ultraviolet-curing marking ink and preparation method thereof

A UV light and marking technology, applied in inks, household appliances, applications, etc., can solve the problems of workers and environmental hazards, and achieve the effect of low VOC emission and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to explain the present invention better, enumerate the specific embodiment of following table for further description. Optimizing the best solution from each example.

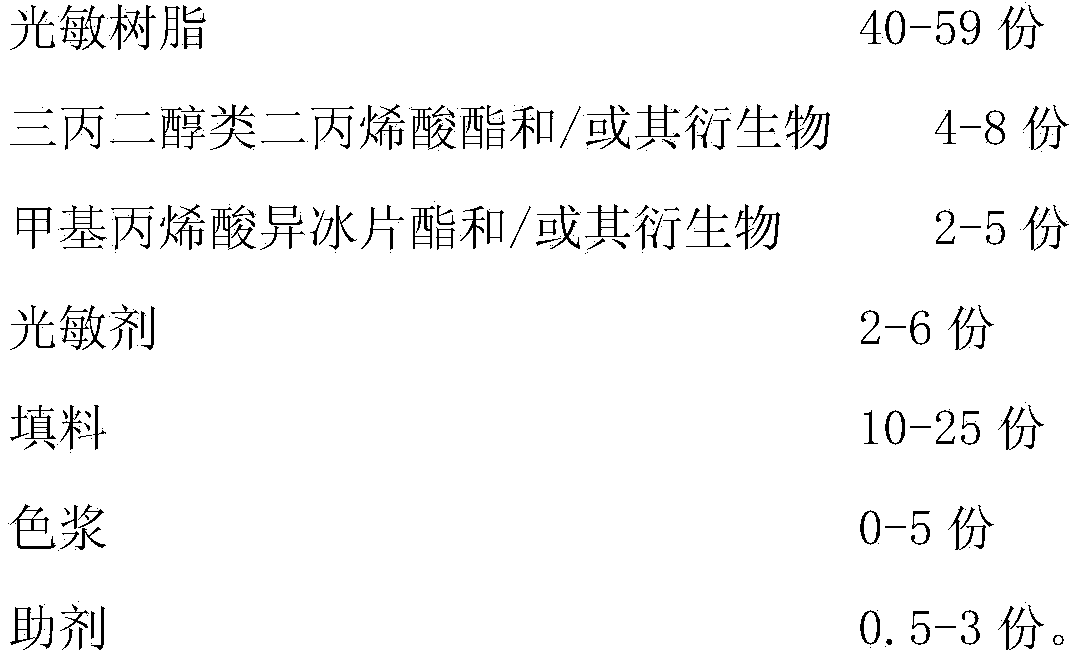

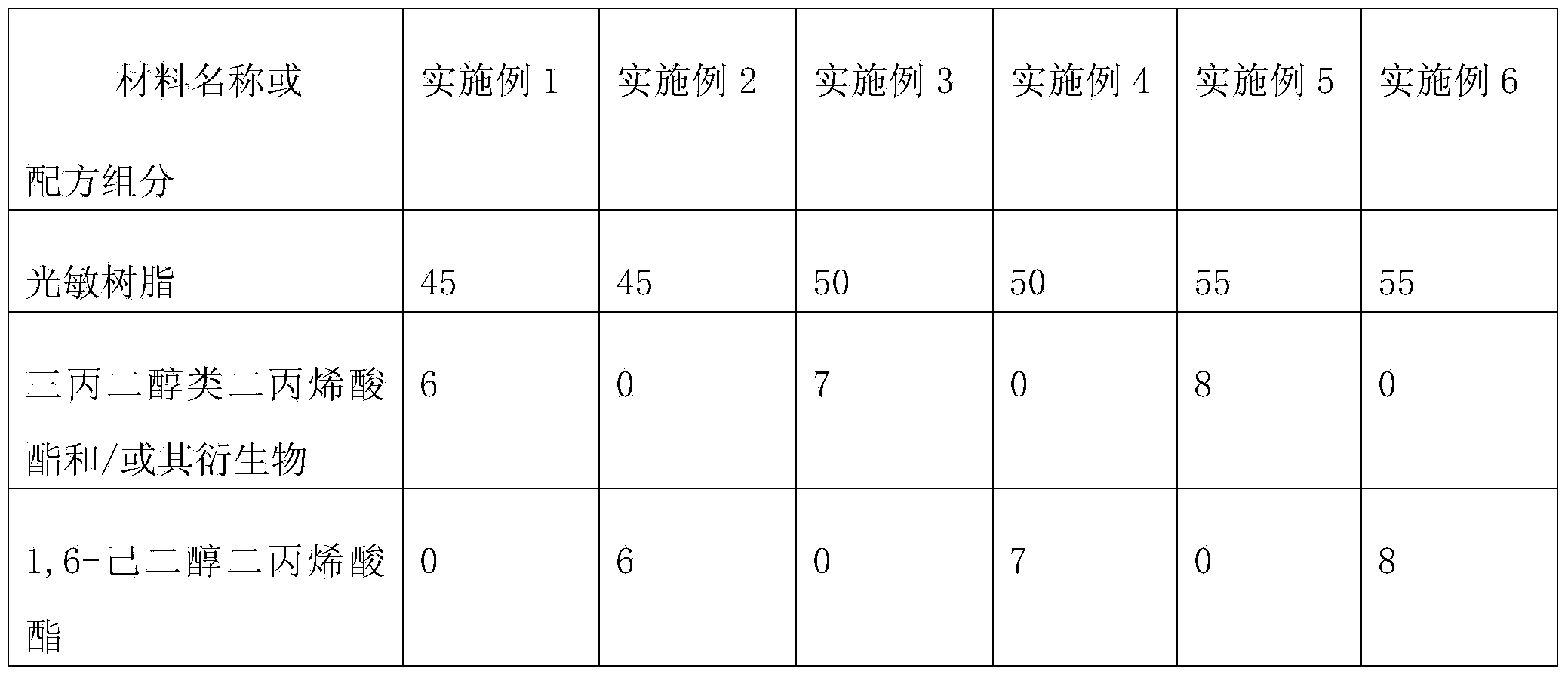

[0033] The formula of table 1 each embodiment of the present invention

[0034]

[0035]

[0036] Table 2 performance of each embodiment product of the present invention

[0037]

[0038] Note: ①Pencil hardness is tested according to GB / T6739-2006 "Determination of Paint Film Hardness by Pencil Method for Paints and Varnishes"; ②Temperature resistance

[0039] The resistance test is the temperature data that the sample coated with solder resist ink can withstand for 10 seconds and three solder resistance tests according to the provisions of GB / T4677-2002.

[0040] From Table 1 and Table 2, it can be seen that Embodiment 1, Embodiment 3 and Embodiment 5 of the present invention are compared with Comparative Reference Embodiment 2, Embodiment 4 and Embodiment 6, using tripropylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com