Double stage compressor cylinder and double stage compressor possessing it

A two-stage compressor and cylinder technology, applied in the field of compressors, can solve problems such as unfavorable medium-pressure circulation channel design and affecting compressor performance, and achieve the effect of improving performance and optimizing positional relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

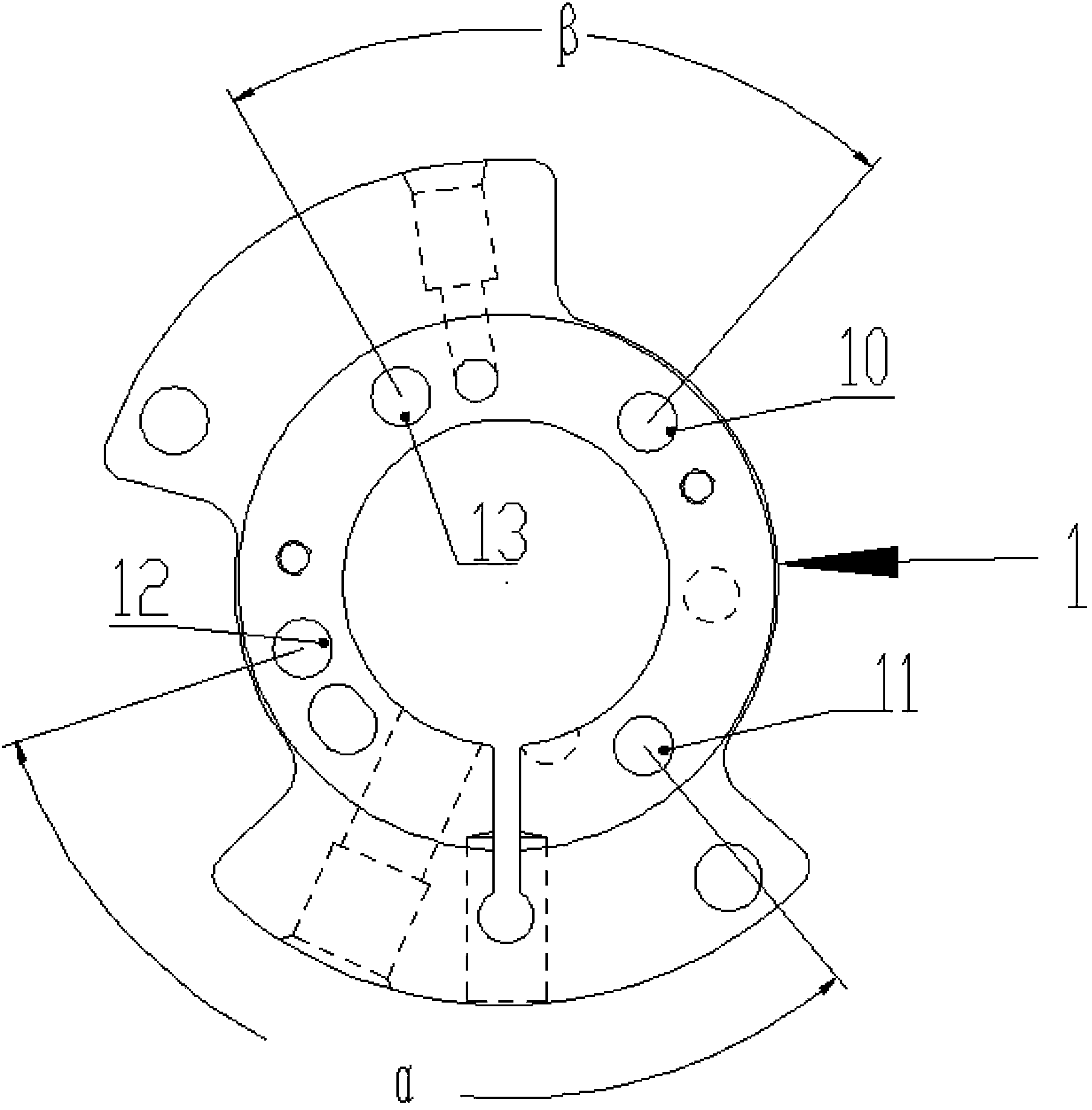

[0022] Such as figure 1 As shown, in order to facilitate the description of the problem, the present invention sets the assembly holes provided on the cylinder as four, that is, N=4, and the largest clip is formed between the adjacent second assembly holes 11 and the third assembly holes 12 on the cylinder 1. Angle α, the minimum angle β is formed between the adjacent first assembly hole 10 and the fourth assembly hole 13 on the cylinder 1. At this time, the maximum angle α, the minimum angle β and the total number of assembly holes N are according to the following relationship: α / (2π / N)0.4 are set, that is, α36°, which ensures that the sealing and deformation of the two-stage compressor are within a reliable range.

[0023] As a preferred embodiment, in the present invention, the maximum included angle α, the minimum included angle β and the total number of assembly holes N are designed according to the following relationship: α / (2π / N)0.5 , that is, when α45°, the distributi...

Embodiment approach 2

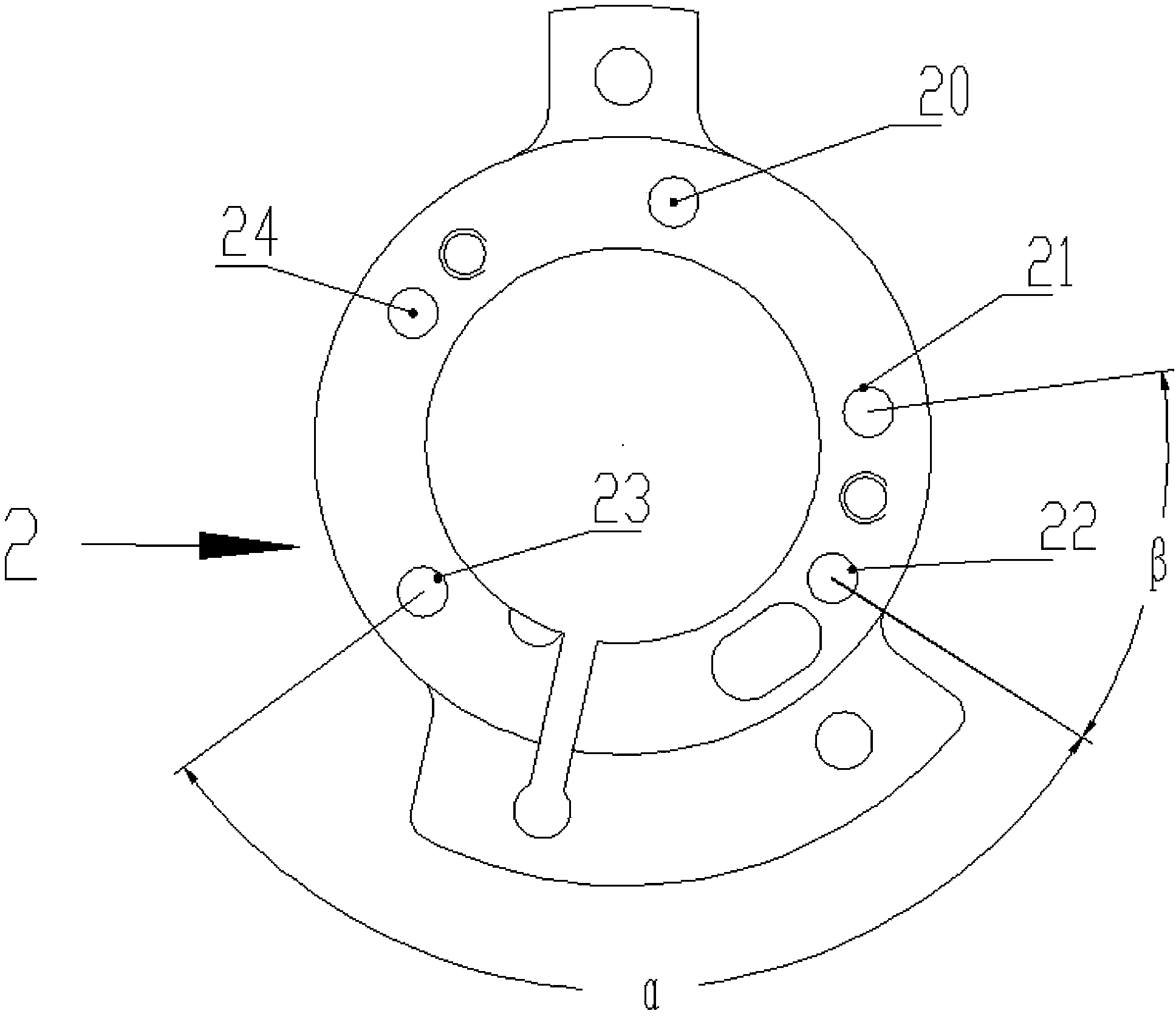

[0028] Such as figure 2 As shown, in this implementation, 5 assembly holes are designed on the cylinder 2, and the rest are the same as in Embodiment 1. This embodiment focuses on the differences from Embodiment 1, and the similarities will not be repeated.

[0029] The largest angle α is formed between the adjacent third assembly hole 22 and the fourth assembly hole 23 on the cylinder 2, and the minimum angle β is formed between the adjacent second assembly hole 21 and the third assembly hole 22 on the cylinder 2 , the adjacent first assembly hole 20 and the fifth assembly hole 24 are disposed close to the second assembly hole 21 and the fourth assembly hole 23 respectively. At this time, the maximum included angle α, the minimum included angle β and the total number of assembly holes N are set according to the following relationship: α / (2π / N)0.4, that is, α28.8° ensures that the sealing and deformation of the two-stage compressor are within a reliable range.

[0030] As a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com