Absolute calibration device and method for radio telescope antenna surface type

A technology for radio telescopes and antenna surfaces, applied to measuring devices, optical devices, instruments, etc., can solve problems such as being easily affected by ambient background light, poor anti-interference ability, high cost, etc., to ensure performance and reduce labor intensity , Easy assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

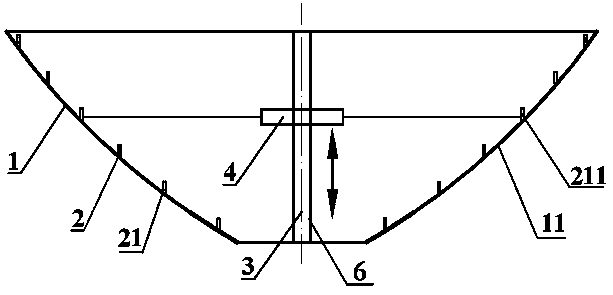

[0032] Such as figure 1 As shown, an absolute calibration device for the antenna shape of a radio telescope is composed of a PSD position sensor array 20, a linear guide 3, a ring laser 4 and a control circuit (not shown in the figure). The PSD position sensor array 20 consists of a number of coaxial The PSD position sensor circle 21 is composed of a linear guide 3 located at the central axis 6 of the main reflecting surface. Each PSD position sensor circle 21 is composed of several PSD position sensor units 211 with the linear guide 3 as the center and the photosensitive surface parallel to the central axis 6 The linear guide 3 is provided with a ring laser 4, the emitting surface of the ring laser 4 is perpendicular to the central axis 6; the control circuit is used to control the PSD position sensor 211 and the ring laser 4 for signal acquisition and signal processing.

[0033] On the main reflecting surface 1 composed of a large number of panels spliced, the PSD positio...

Embodiment 2

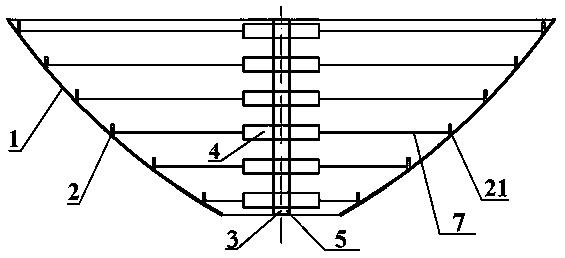

[0042] Such as figure 2 As shown, the difference between this embodiment and the previous example is that the central axis 6 is provided with a support shaft 5, and the support shaft 5 is provided with six ring lasers 4 along the height direction. Each ring laser 4 corresponds to a PSD position sensor ring 21. .

[0043] On the main reflecting surface 1 composed of a large number of panels 11 spliced together, the PSD position sensor unit 211 is placed on the contour circles along the central axis 6 at the position to be measured. The PSD position sensor unit 211 contains PSD, The supporting mechanism and packaging have a highly consistent structural size and installation and positioning interface, and the zero-crossing point is uniformly calibrated in the laboratory, and on the fixed support shaft 5 at a fixed position parallel to the central axis of the main reflecting surface, how accurate is the installation A fixable ring laser 4, through the surface shape formula of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com