Direct reading meter character wheel surface information array method

A surface information and direct-reading meter technology, which is applied to measuring devices, instruments, liquid/fluid solid measurement, etc., can solve problems such as high failure rate, easy jamming of the character wheel, and occupation of the installation space of the character wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

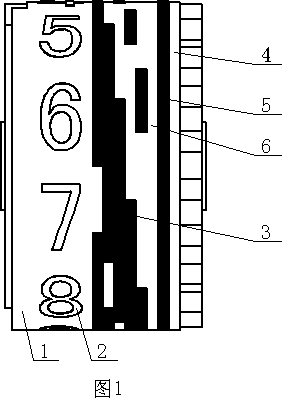

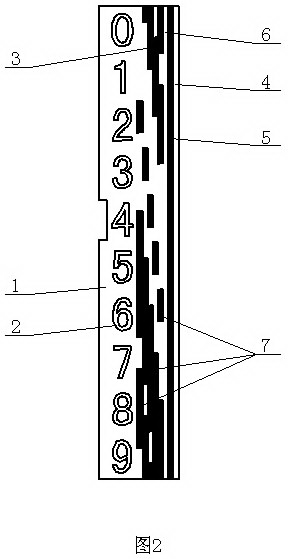

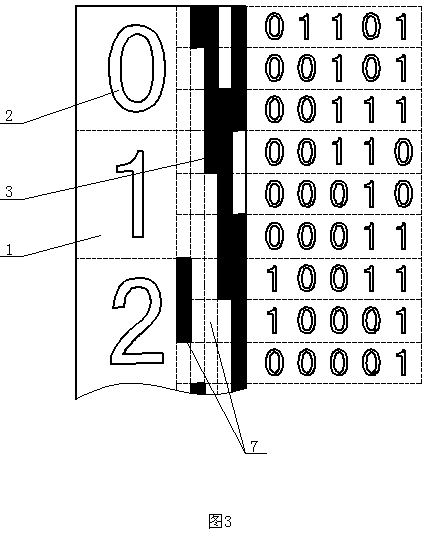

[0008] The technical scheme of the method for arranging information on the surface of the character wheel of a direct reading meter according to the present invention is: comprising axially arranging coding strips and Arabic numerals on the side of the cylinder of the character wheel, at least two coding strips form a group, each group of coding strips Each coding bar in the character wheel is arranged axially on the side of the character wheel cylinder, the array of code bars is arranged circumferentially around the side of the character wheel cylinder, ten Arabic numerals from 0 to 9 are arranged circumferentially around the side of the character wheel cylinder, at least one set The axis of the coding bar corresponds to an Arabic numeral. The main features of the present invention are: the coded strips recording the information on the surface of the character wheel are arranged axially along the side of the character wheel cylinder, and the group of coded strips are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com