High-overload-resistant structure protecting pressure/differential-pressure transmitters

A differential pressure transmitter, high-resistant technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve problems such as damage to single crystal silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

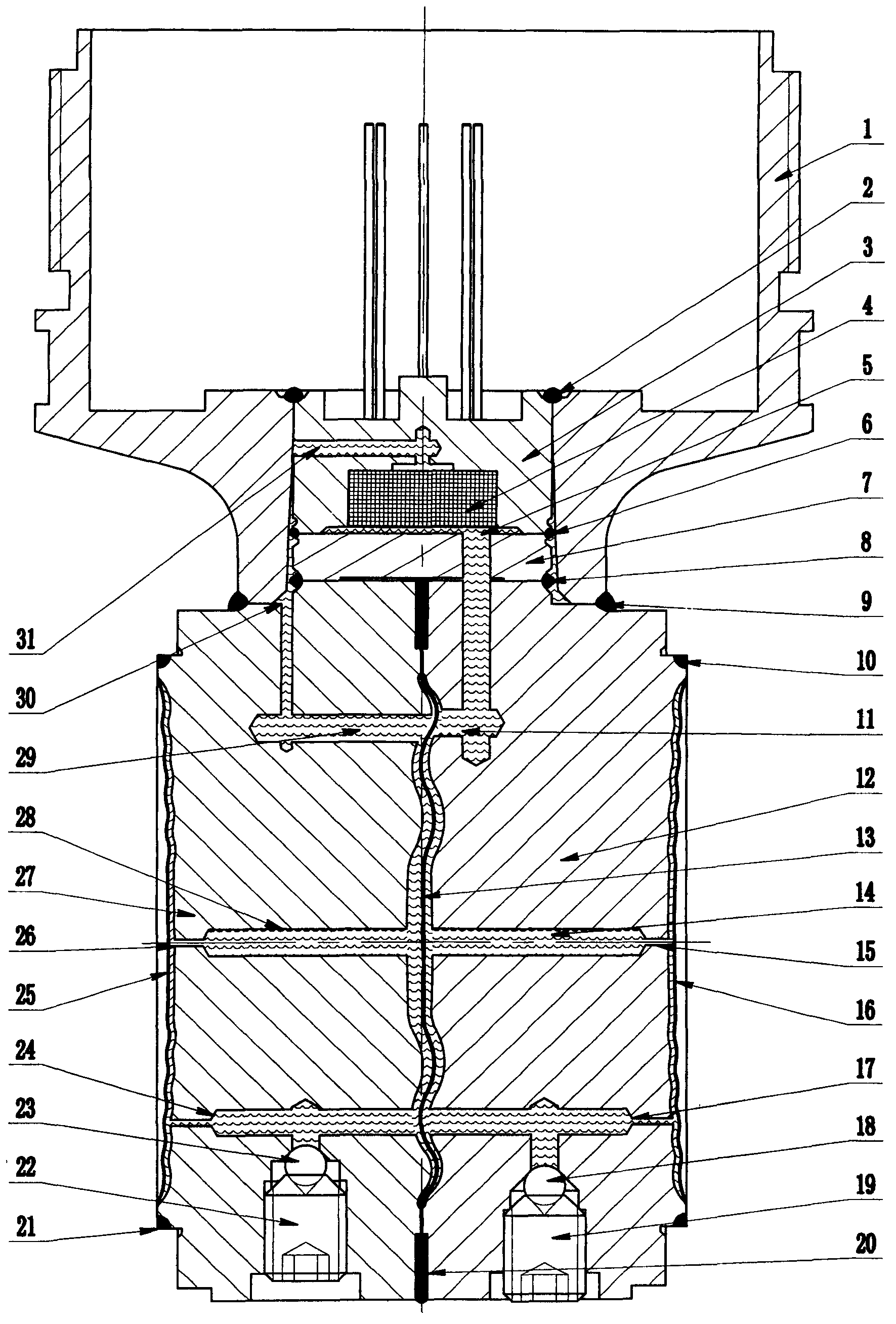

[0018] There is a pair of positive pressure side base 12 and negative pressure side base 27 arranged together. A central diaphragm 13 is arranged between the inner end corrugated surfaces of the positive pressure side base and the negative pressure side base. The upper and lower corrugated outer peripheries of the inner ends of the base on the pressure side and the base on the negative pressure side are fixed together, the upper ends of the base on the positive pressure side and the base on the negative pressure side are fixed with a connecting piece 1, and the positive pressure side A cushion block 7 is arranged at the middle upper end of the base and the negative pressure side base, a silicon sensor 3 is fixed on the upper end of the cushion block, and a silicon chip 4 is arranged at the center of the lower end of the silicon sensor; a positive pressure side is arranged at the center of the positive pressure side base and the cushion block. The pressure introduction hole 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com