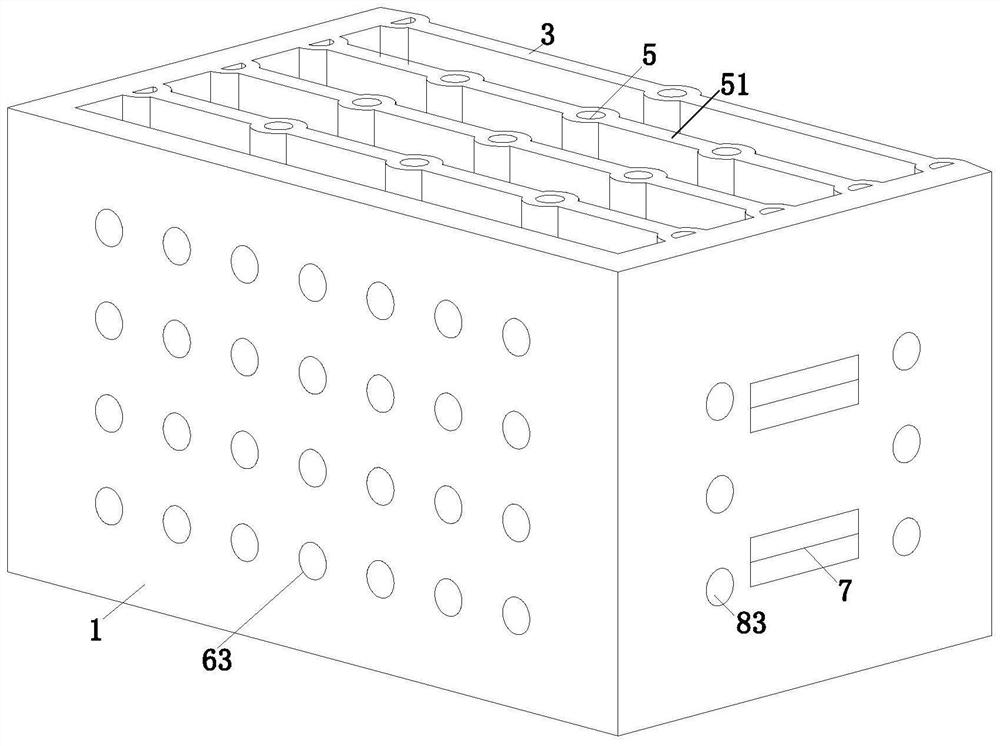

A kind of refractory brick for kiln

A refractory brick and body technology, applied in the field of refractory material manufacturing, can solve the problems of different expansion coefficients between metal and refractory bricks, reduce the thermal insulation performance of refractory bricks, loosen and fall off refractory bricks, etc., to reduce heat loss, improve heat insulation performance, and prevent Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

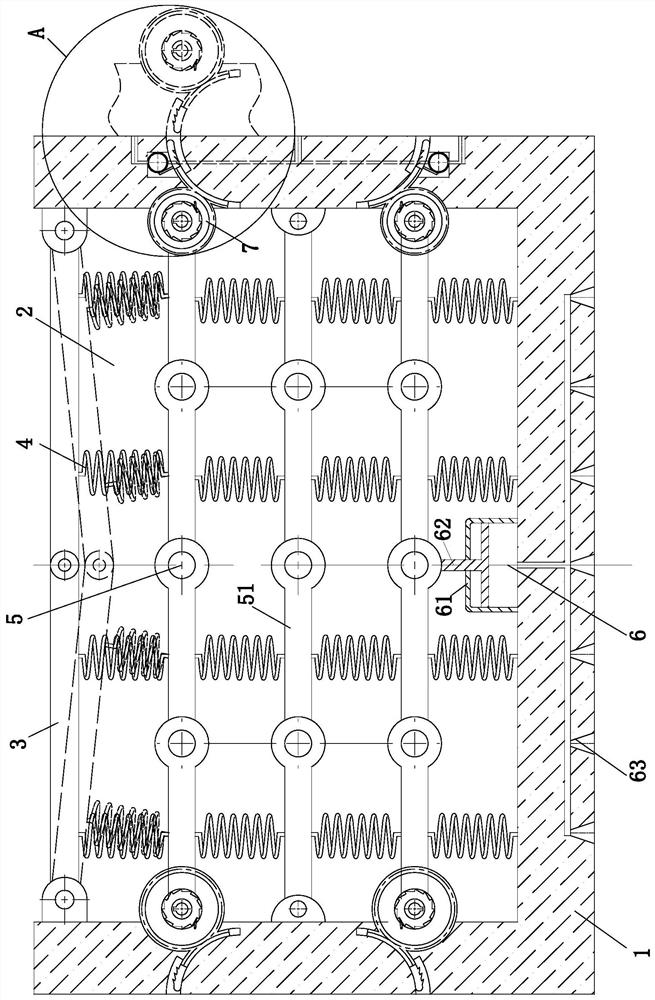

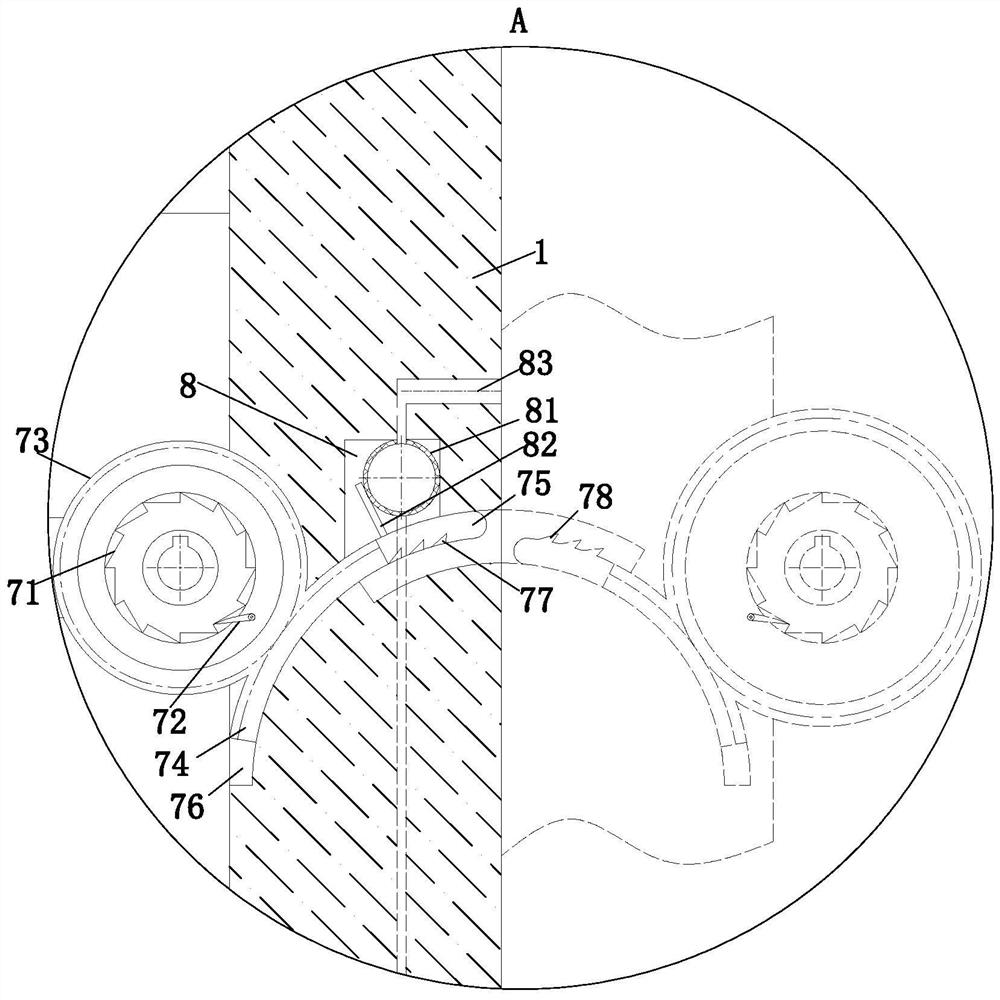

[0023] As an embodiment of the present invention, a set of sawtooth 78 is provided on the outer side of the arc of the bar 75 on one side of the refractory brick body 1; The tooth groove 77; the sawtooth 78 cooperates with the tooth groove 77 to further increase the connection strength of the adjacent firebrick body 1 and prevent the firebrick body 1 from falling off; after the adjacent firebrick body 1 is installed and fixed, the clamping strips 75 are interlaced and inserted In the corresponding slot 76, the elastic sawtooth 78 snaps into the tooth groove 77 to prevent the strip 75 from falling off, further increase the connection strength of the adjacent refractory brick body 1, and ensure the normal operation of the kiln body.

[0024] As an embodiment of the present invention, a cavity 8 is provided in the refractory brick body 1 on the side away from the arc-shaped center of the clip strip 75; a rubber bag 81 is provided in the cavity 8, and a There is mud; the clip 75 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com