Environmental protective automatic continuous paraffin-embedding device

A paraffin embedding and automatic technology, applied in the preparation of test samples, etc., can solve the problems of inconvenience and single function, and achieve the effect of reducing work trouble, convenient observation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

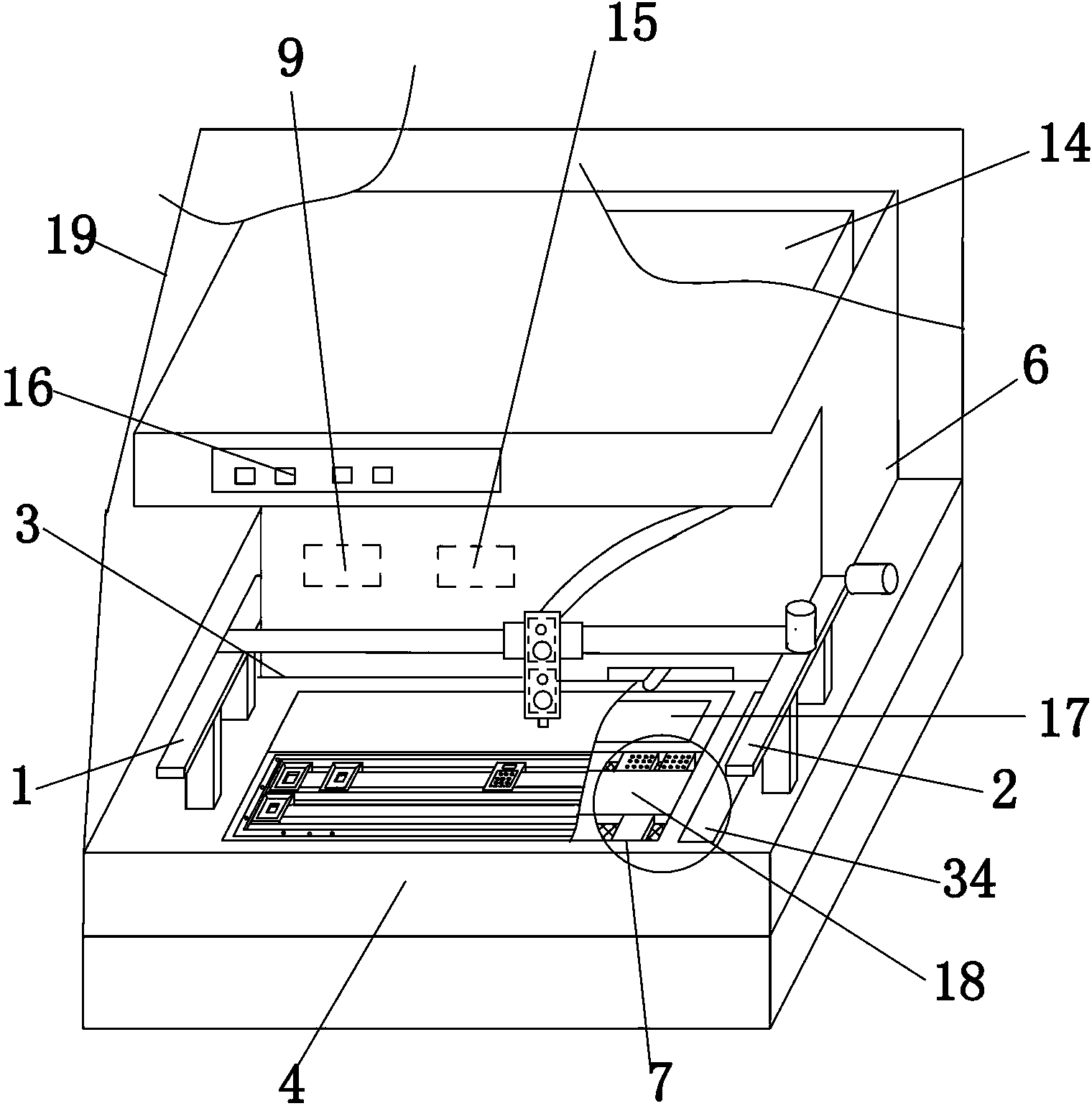

[0041] The environment-friendly automatic continuous paraffin embedding machine includes a housing 6 and a working table 4. The housing 6 is fixed on the workbench 4 .

[0042] A transmission device is provided on the workbench 4 , and the transmission device includes a first guide rail 1 , a second guide rail 2 and a third guide rail 3 . The first guide rail 1 and the second guide rail 2 are fixedly supported on the workbench 4 by two brackets respectively.

[0043] The first guide rail 1 and the second guide rail 2 with the same structure are respectively arranged on both sides of the workbench 4 and are parallel to each other. The two ends of the third guide rail 3 are fixed on the sliders of the first guide rail 1 and the second guide rail 2 respectively. The slider of the first guide rail 1 and the slider of the second guide rail 2 move synchronously.

[0044] A first installation slot 7 is opened on the workbench 4, and a wax box 18 and a cold box 17 are arranged in th...

Embodiment 2

[0058] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0059] A telescopic device is also provided between the wax tube and the slider of the third guide rail 3 , and the telescopic device includes a chute 22 , an upper slider 23 and a lower slider 24 . The upper slider 23 and the lower slider 24 are installed in the chute 22, and the position is set up and down. Two chute positioning holes are provided on the chute 22, and two chute positioning holes are respectively opened on the upper slider 23 and the lower slider 24. Two upper positioning holes 25 and lower positioning holes 26, longitudinally offer two fixing holes on the slide block of the third guide rail 3, the positions of the chute positioning holes, the upper positioning holes 25, the lower positioning holes 26 and the fixing holes correspond to each other.

[0060] The upper positioning hole 25 of the fixing hole, the upper slide block and the chute positioning hole are fixedly assembl...

Embodiment 3

[0068] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

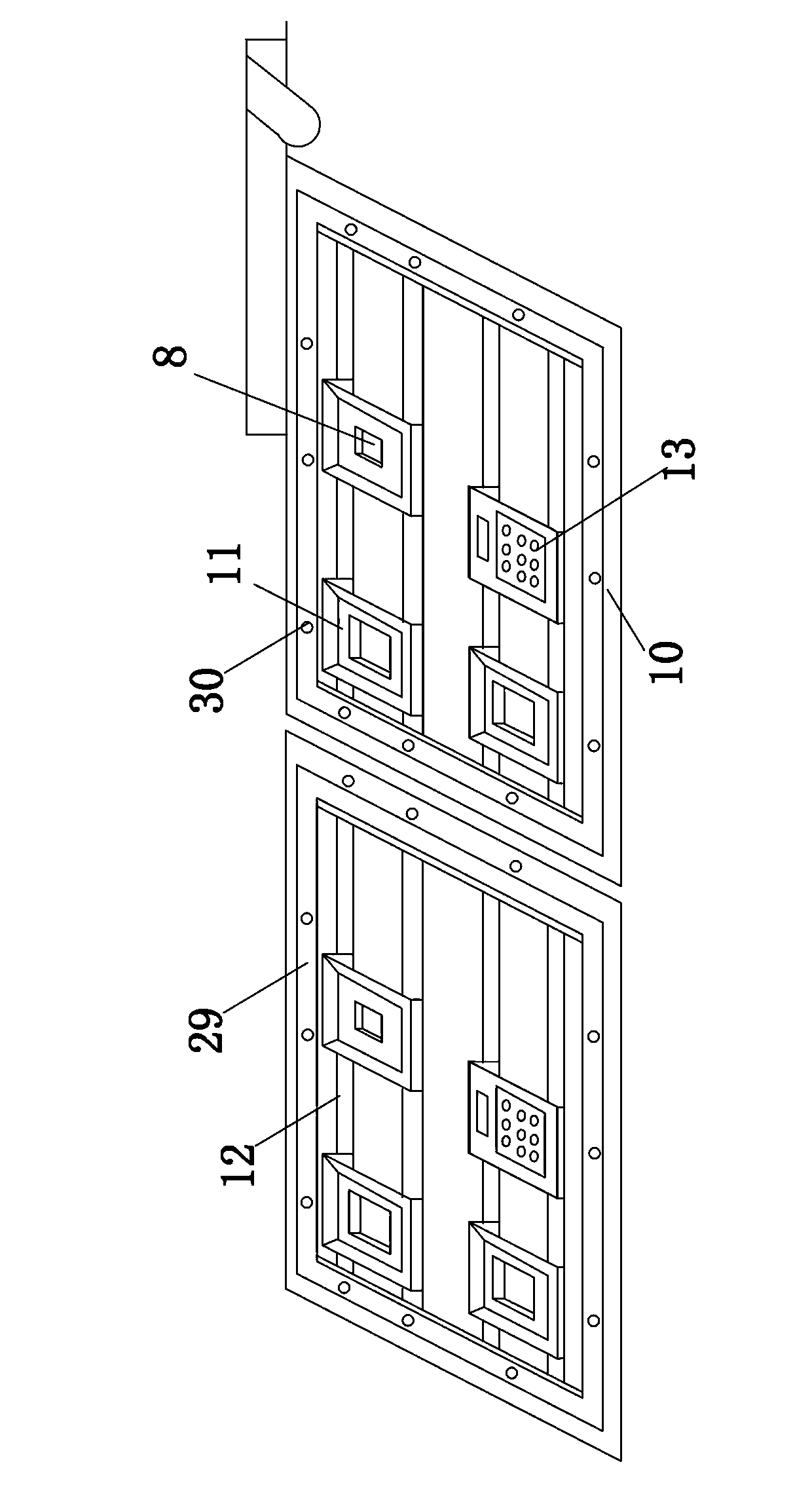

[0069] The embedding mold 11 and the embedding plate 10 are integrally designed. The embedding mold 11 is set on the embedding plate 10 and has an integrated structure with the embedding plate 10, and a wax groove 29 is set on the edge of the embedding plate 10, and a plurality of wax holes 30 are opened in the wax groove 29. (Such as image 3 shown). A cover plate may be provided on the heat tank 34 .

[0070] The heating device is a plurality of electric heating plates, and the plurality of electric heating plates are fixed on the outside of the bottom of the wax holding box 18 and the heat tank 34 . The electric heating plate is a known technology, so it will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com