Model Control Method of Heating Furnace Temperature

A technology of model control and heating furnace, applied in the direction of temperature control, adaptive control, general control system, etc., can solve the problems of energy waste, abnormal heating quality of products, abnormal measurement accuracy of furnace temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of model control method of heating furnace temperature, comprises the following steps:

[0041] Step 1. First, based on the actual production performance data, establish a gas statistical sample for each single product in the heating furnace under a stable production rhythm, and match the product index with the gas statistical sample one by one to represent the best furnace condition in the actual production process; content as follows:

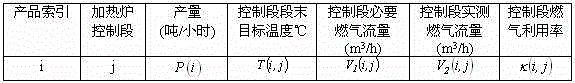

[0042]

[0043] Stable production rhythm for a single product: The steel grades and specifications of the products heated in the heating furnace are exactly the same, the product index is i, and the steel pumping rhythm of the heating furnace is stable, and the unique index corresponding to the specific steel grade and specific specification;

[0044] The actual temperature of the single product with index i at the end of the jth control section under the stable production state, which is obtained by tracking the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com