A kind of 160mm thick q235c low compression bit thick steel plate and its preparation method

A technology of extra-thick steel plate and bit reduction, which is applied in the field of metallurgy, can solve problems such as low yield, slow production cycle, and harsh production environment, and achieve the effects of fast production rhythm, stable production process, and uniform structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

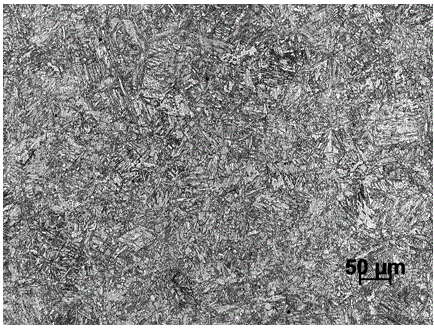

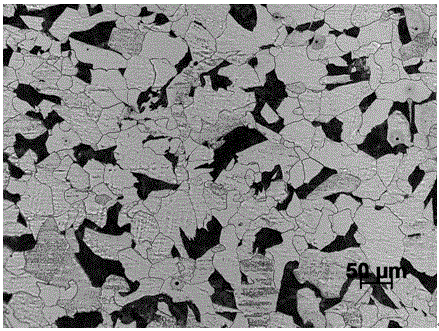

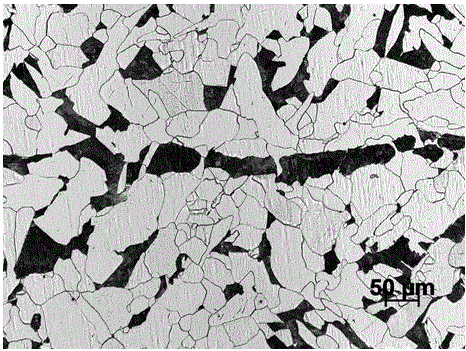

[0027] Examples 1-2 are a 160mm thick Q235C steel plate and its manufacturing method. It adopts a medium-carbon, low-phosphorus, low-sulfur smelting process, adopts one-stage rolling and reciprocating water cooling technology, and the main production process route is: hot metal desulfurization pretreatment →Converter smelting→LF refining→RH refining→Continuous casting→Slab inspection and judgment→Slab acceptance→Slab heating→Descaling→Rolling→Cooling→Flaw detection→Cutting, sampling→Spray printing mark→Storage.

[0028] The main chemical composition of embodiment 1~2 is as shown in table 1:

[0029] Table 1 Main chemical composition (wt%) of the embodiment of the present invention

[0030] Example

C

Si

mn

P

S

Alt

Ceq

Example 1

0.15

0.21

0.91

0.0017

0.0025

0.028

0.31

Example 2

0.14

0.19

1.20

0.0014

0.0019

0.035

0.34

[0031] As can be seen from Table 1, the chemical composition of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com