A pre-smelting process for electrolytic aluminum liquid

A technology for electrolysis of molten aluminum and pre-smelting, applied in the field of aluminum processing, can solve problems such as low cost, low pollution, high pollution, etc., and achieve the effects of reducing the pressure of subsequent processing, improving cleanliness, and reducing slag and burning loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: 100% electrolytic aluminum solution production of anodic oxidation 6063 alloy rod

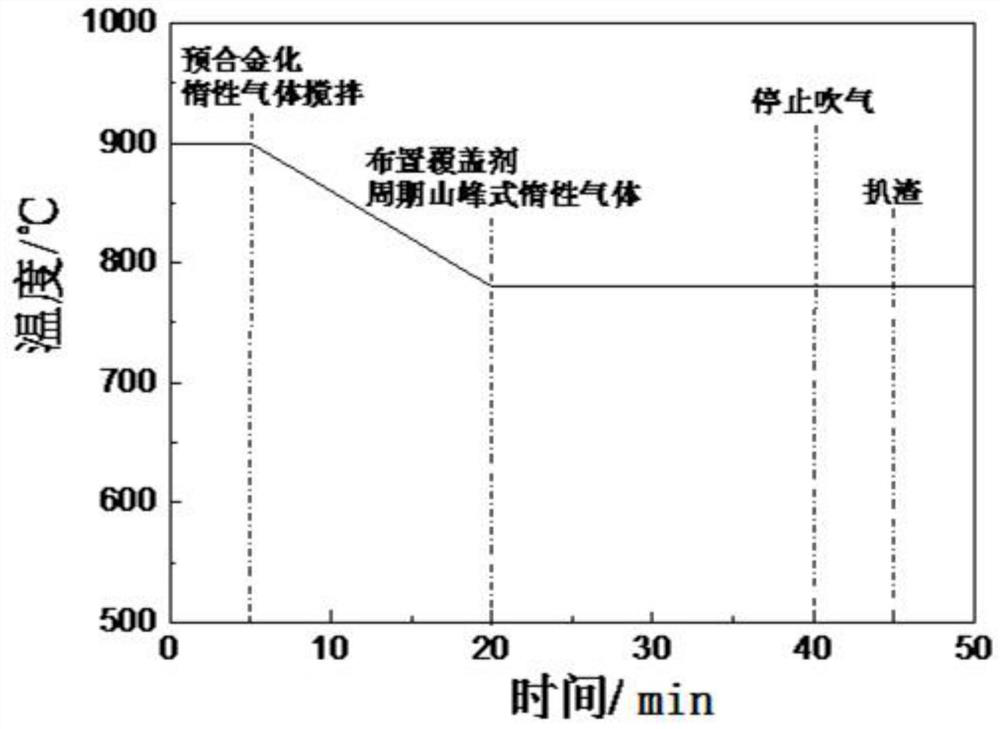

[0067] (1) The vacuum package has an aluminum capacity of 8T. After the electrolyte aluminum liquid enters a vacuum package, the test residue content is 0.28 mm. 2 / kg, hydrogen content was 0.39 ml / 100g. After 160kg of aluminum silicon (20%), after the bottom of the vacuum packet was blown into high purity argon, the flow rate was 12 l / h, the pressure was 0.6 MPa.

[0068] (2) After 15 min, the intermediate alloy is completely melted, and the cover is arranged on the surface of the aluminum melt, and the gas flow peak is 5 l / h, the gas flow rate is 0.5 MPa, the time period is 8 minutes, and the cycle 3 Second-rate.

[0069] (3) Also stand for 5 min and remove the cover.

[0070] Sampling test residue content is 0.13mm 2 / kg, the hydrogen content was 0.23 ml / 100g. After the pre-melting refining, the Si content was 0.39%, and the component fine tuning after transferring th...

Embodiment 2

[0071] Example 2: Predicted 100% electrolytic aluminum liquid production high-end wire 5183 alloy rod

[0072] (1) The vacuum package used each time the aluminum capacity is 6T, and the electrolytic aluminum liquid enters the vacuum package, first test the residue content of 0.31 mm. 2 / kg, hydrogen content was 0.38 ml / 100g. After 250 kg of the magnesium ingot, it was started to blow high purity argon gas from the bottom of the vacuum pump, and the flow rate was 10 l / h, and the pressure was 0.6 MPa.

[0073] (2) After 15 minutes, the intermediate alloy is completely melted, and the cover is arranged on the surface of the aluminum melt, and the gas flow rate is 4 L / h, the gas flow peak is 0.5MPa, the time period is 6 minutes, and the cycle 4 is 6 minutes according to the cycle peak. Second-rate.

[0074] (3) Also stand for 5 min and remove the cover. Sampling test residue content is 0.14mm 2 / kg, the hydrogen content was 0.21 mL / 100g. After the pre-melting refining, the Mg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com