Water-culture planting device

A planting device and hydroponics technology, applied in the fields of cultivation, soilless cultivation, botany equipment and methods, etc., can solve problems such as difficulty in realizing batch cultivation, inability to realize multi-layer stacking, and relatively high strength requirements for planting bed materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

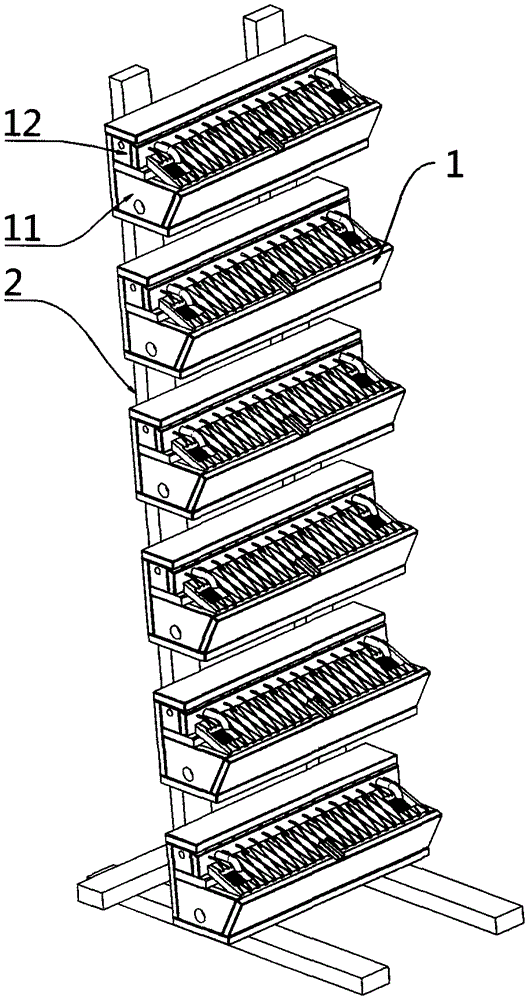

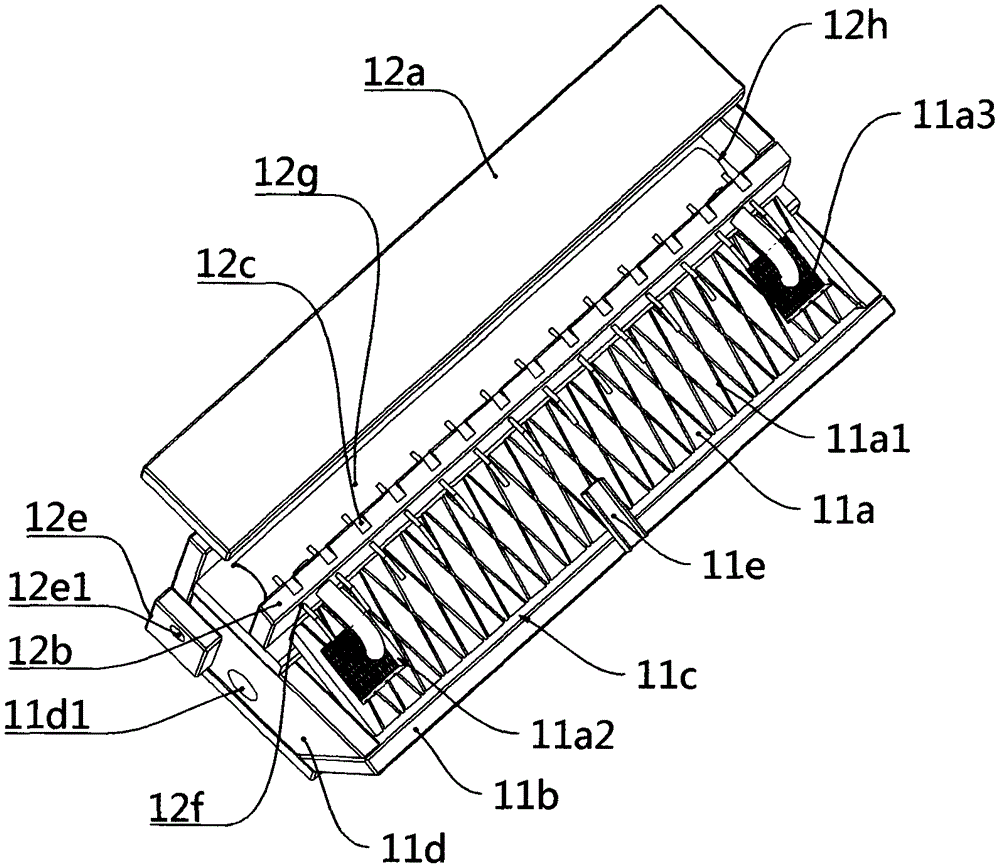

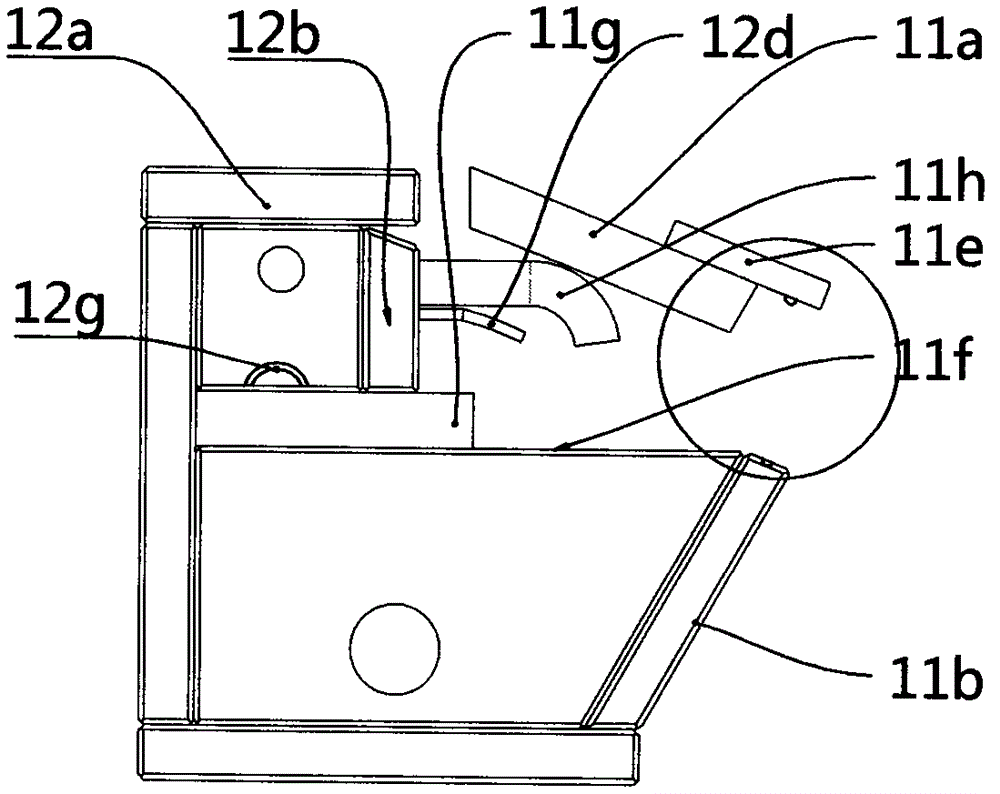

[0034] Embodiment 1: as Figure 1 to Figure 3As shown, a hydroponic planting device, the hydroponic planting device 1 includes a cultivation pool 12 and a liquid storage tank 11 arranged up and down, and the cultivation pool 12 and the liquid storage tank 11 are respectively connected to the corresponding water inlet 12e1 and water outlet 11d1; The hydroponic planting device 1 is fixed on the supporting frame 2 at equal intervals up and down in multiple layers, and the water outlet 11d1 of the liquid reservoir 11 on the upper layer is connected to the water inlet 12e1 of the cultivation pool 12 on the next layer; the side wall 12b of the cultivation pool 12 is set Several planting holes 12c and overflow flow holes 12f connected to the inner wall and outer wall of the side wall 12b of the cultivation pond 12, several planting holes 12c and overflow flow holes 12f are set at the same height respectively and the height of the overflow flow holes 12f is lower than the planting hole...

Embodiment 2

[0045] Embodiment 2: as image 3 In this embodiment, on the basis of Embodiment 1, it is further set that two rows of planting holes 12c and overflow channels are symmetrically arranged on the two side walls 12b corresponding to the two side walls 12b of the cultivation pool 12 of the elongated tank body in the axial direction. The hole 12f and the liquid storage tank 11 are provided with two corresponding openings 11f and the heat-conducting cover plate 11a thereof; the corresponding planting device can realize planting on the two side walls 12b, 11b of the cultivation tank 12 and the liquid storage tank 11 respectively. , increasing the planting area of a single planting device, thereby greatly increasing the planting area of a multi-layered planting device, and facilitating the realization of industrialized planting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com