Stamping die of shock-absorbing liner bushing inner sleeve and machining method of stamping die

A technology of shock-absorbing bushings and stamping dies, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, and fast tool wear, and achieve simple and safe operation and high production efficiency , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

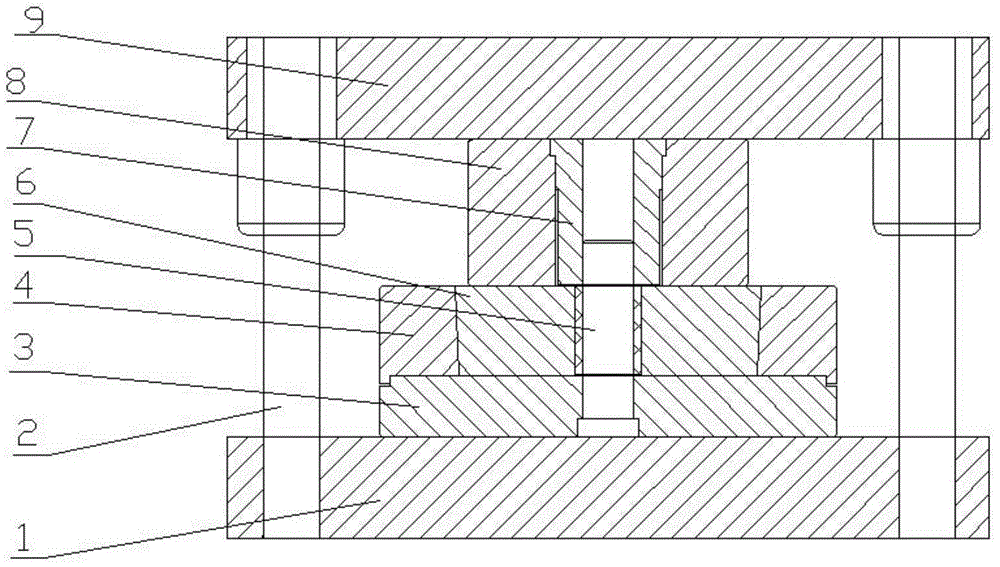

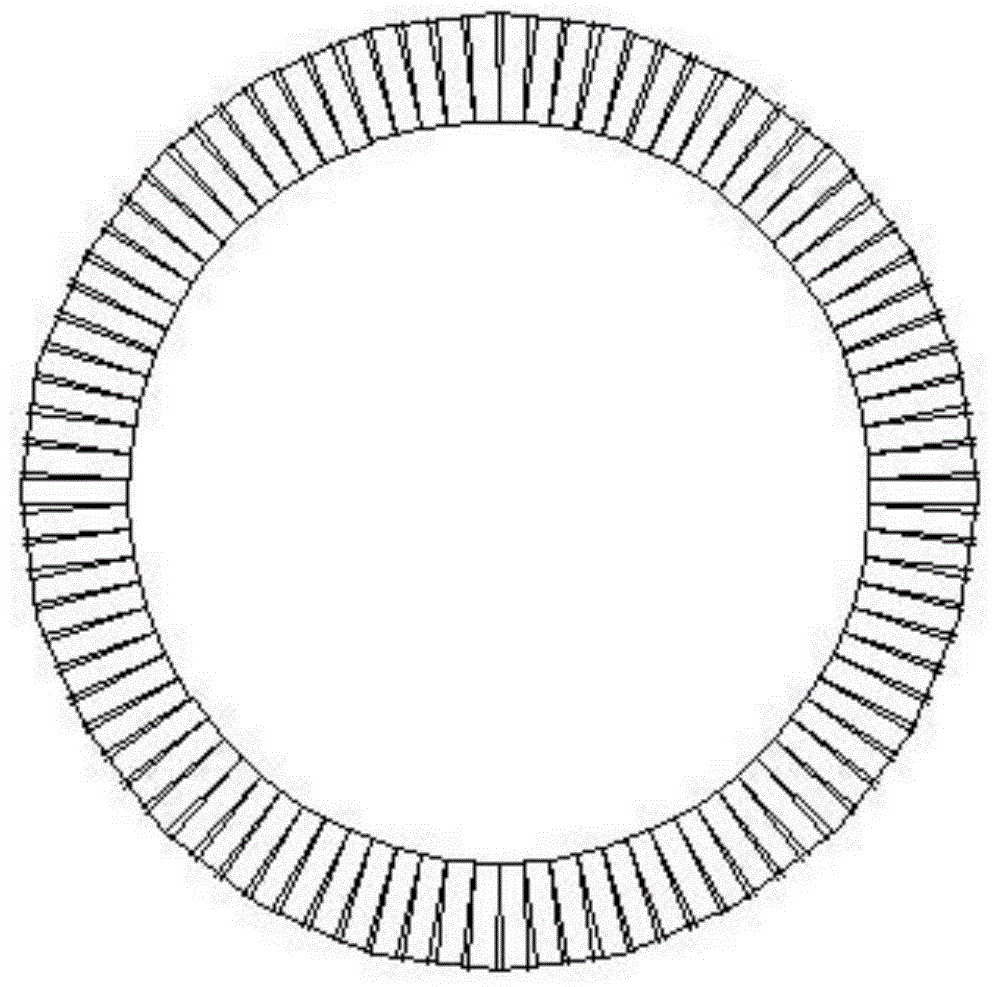

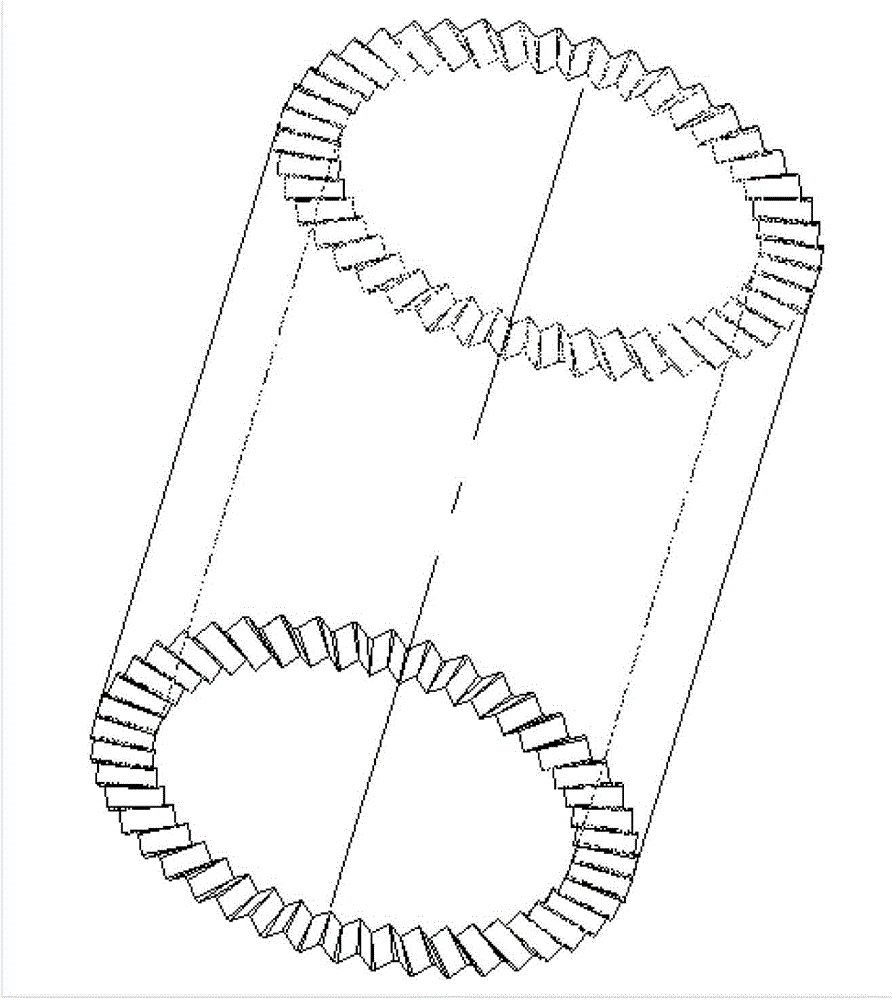

[0023] combine figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 The stamping die of the shock-absorbing bush inner sleeve shown includes an upper plate 9, a bottom plate 1, a positioning core 5, an upper mold fixing block 8 and a fixing ring 4; the outer edge of the upper plate 9 and the bottom plate 1 moves through two guide pillars 2 The two guide posts 2 are symmetrically distributed in the center; the bottom side of the upper plate 9 is connected with the upper die 7, and the center of the upper die 7 is provided with a first through hole, and the circumference of the bottom end of the first through hole is provided with a raised cutting edge of the upper die 10. The shape of the raised cutting edge 10 of the upper mold matches the sawtooth at the top of the inner sleeve of the shock-abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com