Corrugated box feeding device

A corrugated box and pole technology, which is applied in the field of corrugated box feeding devices, can solve the problems of high labor intensity and no reduction in the workload of handling corrugated paper, and achieve the effects of reduced work risk, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

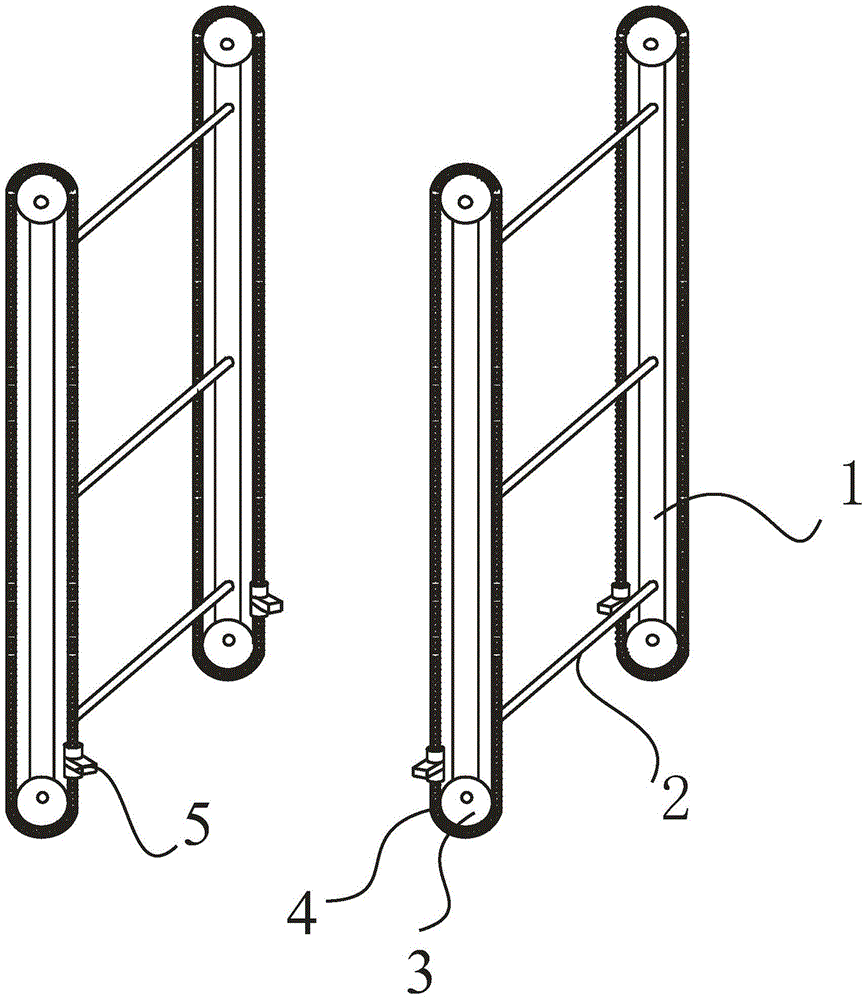

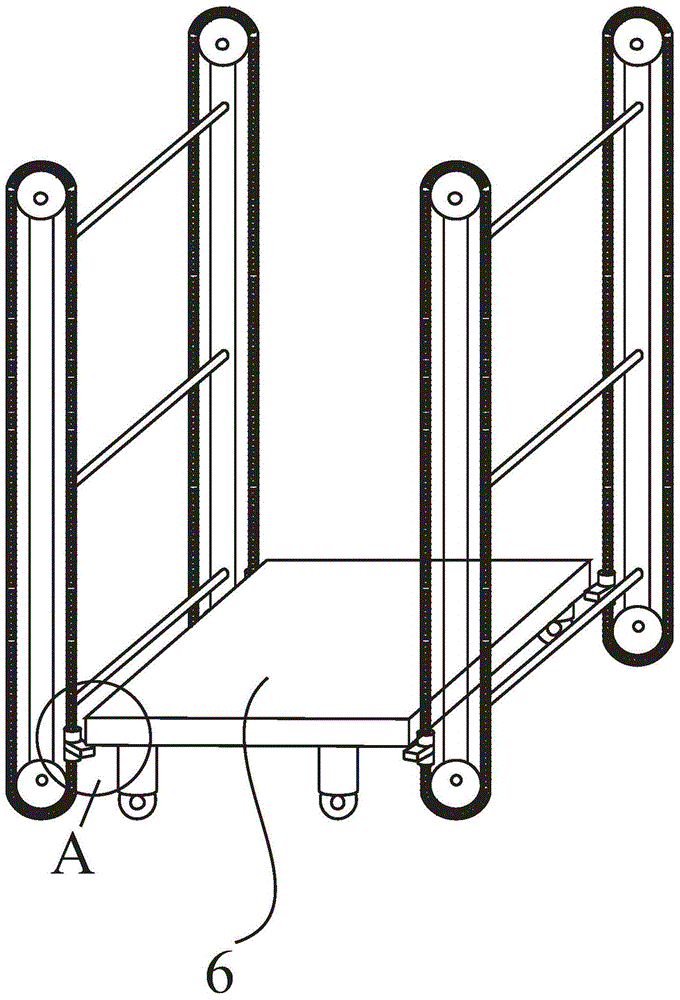

[0016] Such as figure 1 As shown in , a corrugated box feeding device includes two frames fixed to the ground and a transport vehicle 6, the frame includes a pole 1 and a crossbeam, which are welded and fixed between the two; the two poles of the pole 1 The ends are respectively provided with runners 3 , and the outer circumference of the runners 3 is provided with a rack 4 surrounding the vertical pole 1 , and the runners 3 are connected with a transmission; the rack 4 is fixedly connected with a pin 5 .

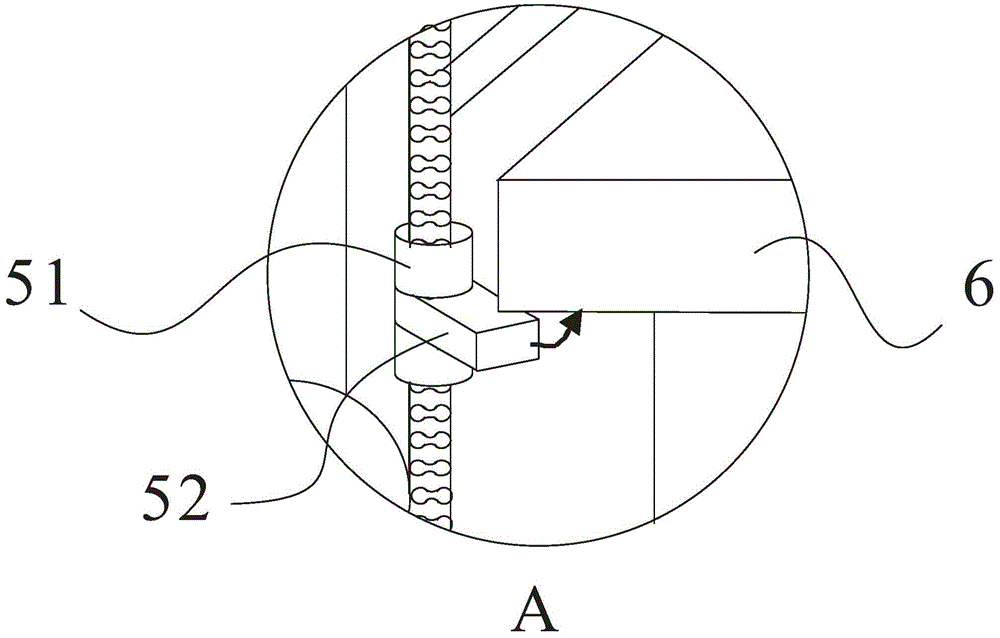

[0017] Such as image 3 As shown, the pin shaft 5 is a rotating pin shaft, and the rotating pin shaft includes a column 51 and a cross arm 5 , and the cross arm 5 can rotate around the column 51 .

[0018] The column 51 is welded to the rack 4 .

[0019] When working, the rack 4 is driven upward by the runner 3 on the pole 1, and the pin shaft 5 fixed on the rack 4 will also move upward, and the pin shaft 5 is located under the transport vehicle 6, which will drive the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com