Copper belt automatic winding and disc changing process and device with clutch telescopic shaft

A technology of telescopic shaft and copper strip, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., to achieve the effect of reliable action, simple structure and simplified mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

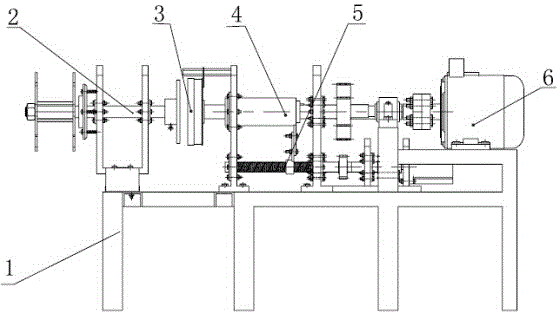

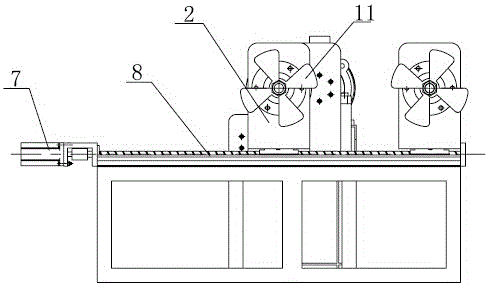

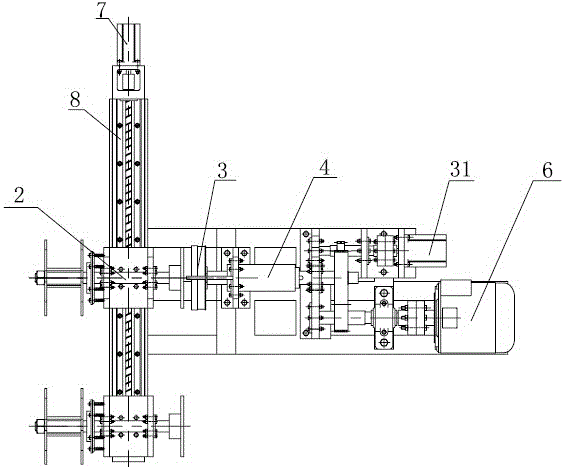

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] As shown in the figure, the copper strip automatic winding and disc changing process with a clutch telescopic shaft described in the present invention is specifically: the winding starts, the telescopic shaft is at the limit position of elongation, and the stopper 12 of the winding disc changing assembly 2 and The winding reel 11 is spaced for a certain distance, and the copper tape enters the space between the baffle disk 12 and the winding reel, and the telescopic shaft retreats, so that the baffle disk and the winding reel press the copper tape together, that is, the clamping and locking of the copper tape is completed. crimping motion; then carry out winding motion, when winding just started, ensure that the head of the copper strip is wound under the clamping state of the baffle plate 12 and the winding reel 11, after winding a certain number of turns, it is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com