High solids water-based clear paint

A high solid content, clear paint technology, applied in the direction of coating, can solve the problems of low solid content of water-based resin, difficult to achieve fullness and transparency of clear paint, etc., to improve filling, improve film fullness, coating smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

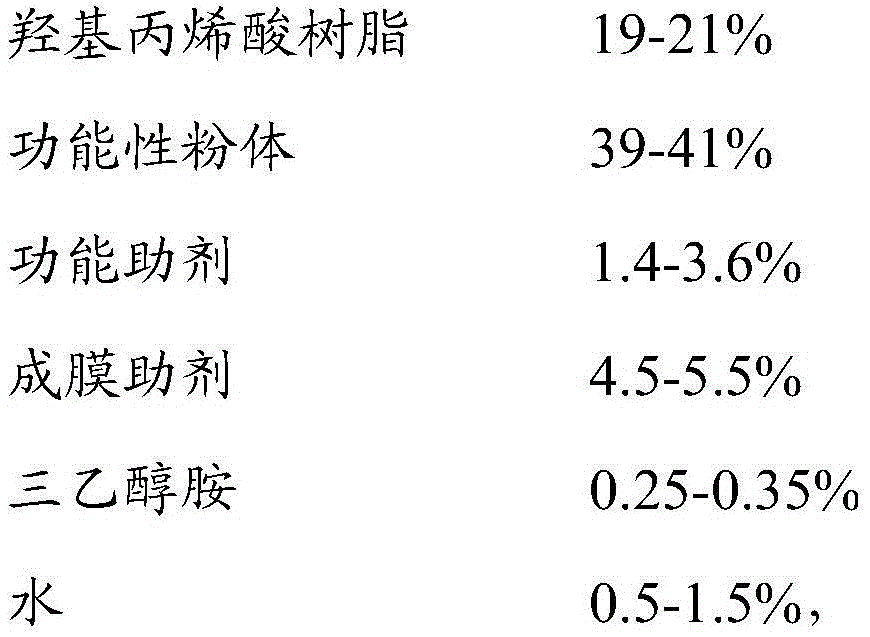

[0028] The present embodiment is a kind of high solid content waterborne transparent paint, comprises the raw material component of following mass percentage composition:

[0029]

[0030]

[0031] Wherein the functional powder includes the following raw materials in parts by weight:

[0032] 25 parts by weight of high acid value (69-80mgKOH / g) carboxyl-terminated polyester resin P5500;

[0033] 50 parts by weight of medium acid value (32-38mgKOH / g) carboxyl-terminated polyester resin SJ4E;

[0034] Low acid value (18-25mgKOH / g) carboxyl-terminated polyester resin P883 25 parts by weight.

[0035] The mass content of the hydroxyl group in the hydroxyl acrylic resin is 0.2-0.4%.

Embodiment 2

[0037] The present embodiment is a kind of high solid content waterborne transparent paint, comprises the raw material component of following mass percentage composition:

[0038]

[0039]

[0040] Wherein the functional powder includes the following raw materials in parts by weight:

[0041] 30 parts by weight of high acid value (69-80mgKOH / g) carboxyl-terminated polyester resin P5500;

[0042] Medium acid value (32-38mgKOH / g) carboxyl-terminated polyester resin SJ4E 40 parts by weight;

[0043] 30 parts by weight of low acid value (18-25 mgKOH / g) carboxyl-terminated polyester resin P883.

[0044] The mass content of the hydroxyl group in the hydroxyl acrylic resin is 0.2-0.4%.

Embodiment 3

[0046] The present embodiment is a kind of high solid content waterborne transparent paint, comprises the raw material component of following mass percentage composition:

[0047]

[0048]

[0049] Wherein the functional powder includes the following raw materials in parts by weight:

[0050] High acid value (69-80mgKOH / g) carboxyl-terminated polyester resin P5500 35 parts by weight;

[0051] Medium acid value (25-35mgKOH / g) carboxyl-terminated polyester resin SJ4E 30 parts by weight;

[0052] Low acid value (18-25mgKOH / g) carboxyl-terminated polyester resin P883: 35 parts by weight.

[0053] The mass content of the hydroxyl group in the hydroxyl acrylic resin is 0.2-0.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com