Method For Detecting Changes Of Position Of Shaftless Spinning Rotor And Spinning Unit

一种纺纱单元、转杯的技术,应用在纺纱机、轴和轴承、测量装置等方向,能够解决不能获得附加空间、昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

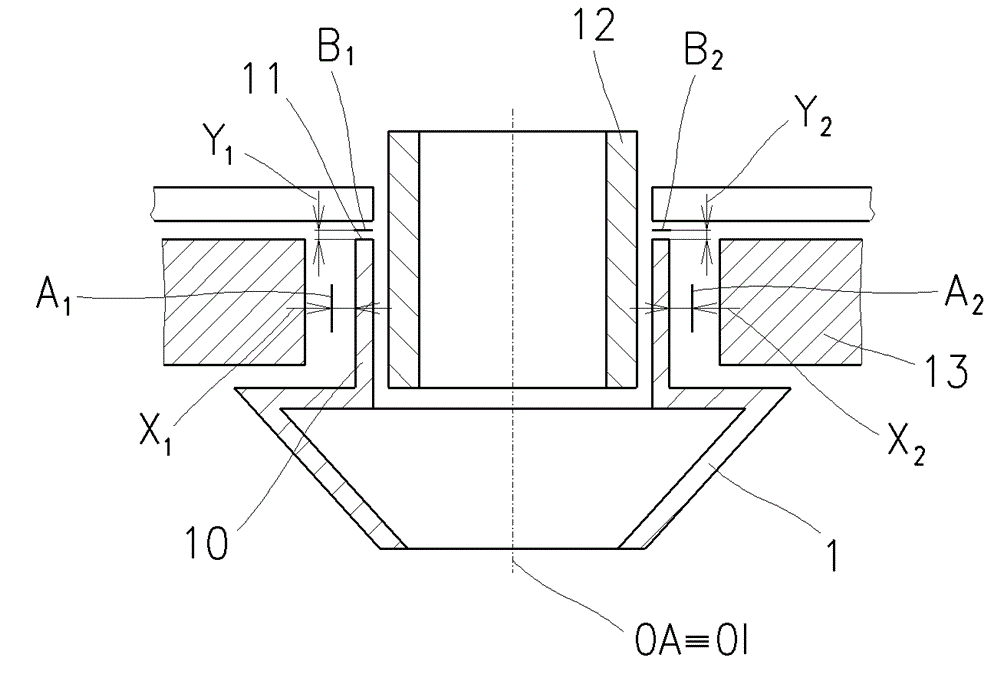

[0013] From the following description of an example of an embodiment of an active magnetic bearing with a shaftless spinning rotor for a spinning unit of an open-end spinning machine, the present invention will become clearer.

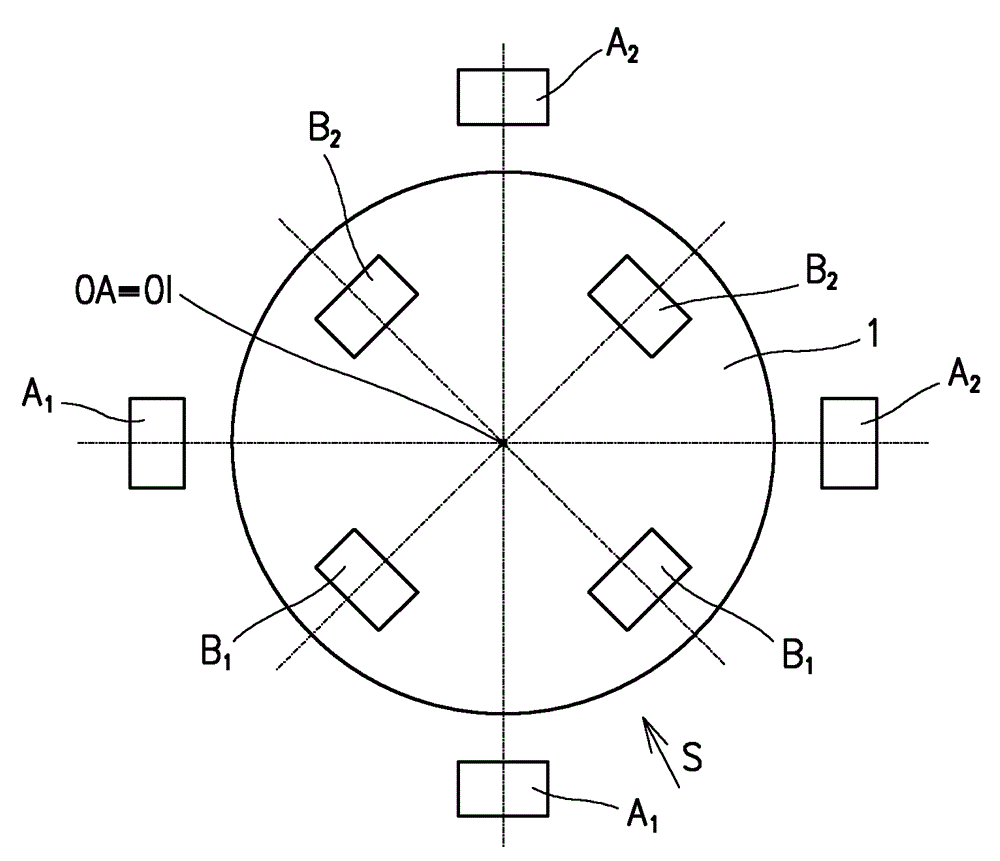

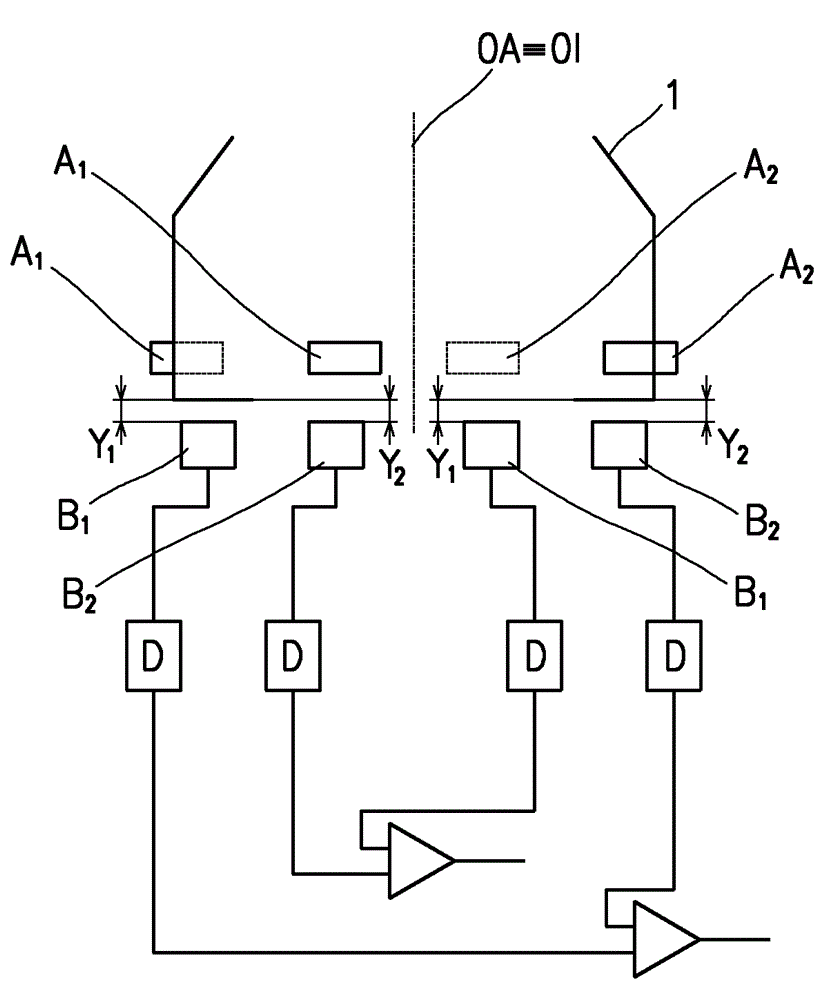

[0014] The open-end spinning machine includes at least one row of operating units positioned adjacent to each other. In addition to a number of other components, each operating unit also includes a spinning unit arranged with an active magnetic bearing, and the shaftless spinning rotor 1 is rotatably installed in the active magnetic bearing. The active magnetic bearing ensures that the position of the spinning rotor 1 relative to the other components of the spinning unit is maintained by the controlled magnetic stabilization system 13. The driving of the spinning rotor 1 is ensured by a controlled electromagnetic driving system 12.

[0015] Below the position of the spinning rotor 1, we understand that the spinning rotor 1 is positioned in a three-dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com