A pit-in-pit steel drum drainage method

A pit-in-pit and steel-drum technology, which is applied in construction, infrastructure engineering, etc., can solve problems such as high cost, complicated operation, and poor water-stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

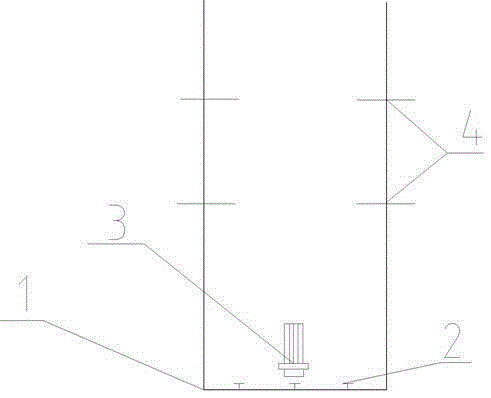

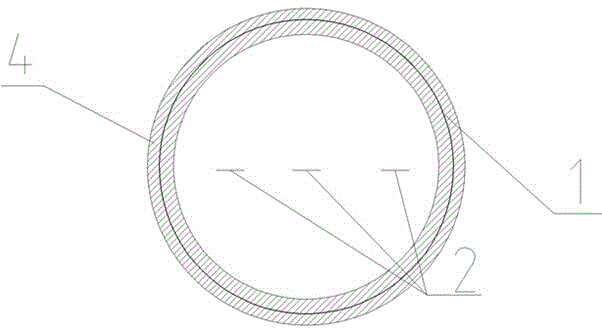

[0024] Attached below Figure 1-4 And embodiment, the present invention is described further.

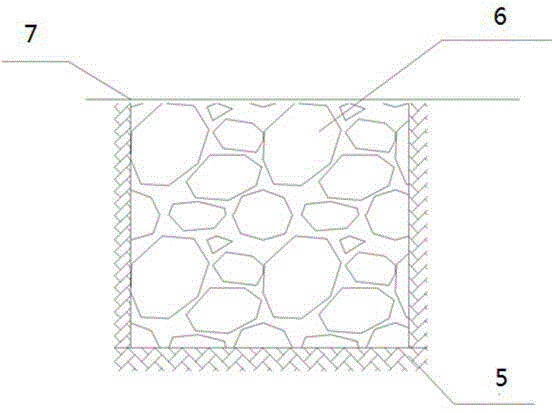

[0025] A pit-in-pit steel drum dewatering method, the implementation steps are: making a cylindrical steel drum (1) with a diameter of 800 mm to 1200 mm and a thickness of 5 mm, the height of which is determined by the thickness of the poured raft. Holes are opened at the bottom of steel drums (1) and gate valves (2) are installed, and water-stop rings (4) are welded around each 3000mm long steel drum (1). (8) Fill the bottom with a thickness of 100mm, introduce the water from other leaking points into the pit through the blind ditch, then put the steel drum (1) into the pit filled with the centimeter stone (8), and then use the centimeter stone (8) Fill up around the bottom of the steel drum (1), fill the blind ditch with dog head stones (6), and cover with a plastic film (7). Water from other leaking points is introduced into the deep pit through the blind ditch and enters throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com