Regeneration opportunity control method for DPF (Diesel Particulate Filter) of diesel engine

A particle trap and regeneration timing technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of burning out carriers, local carbon load exceeding the standard, and uneven carbon adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

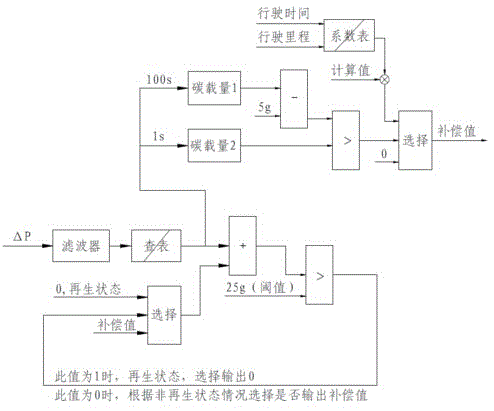

[0018] See figure 1 The present invention uses a differential pressure sensor to collect the differential pressure signal ΔP at both ends of the DPF, and obtains the DPF (Diesel Particulate Filter) carbon load corresponding to the filtered ΔP by referring to the correspondence table between the differential pressure value and the carbon load (soot) estimated value.

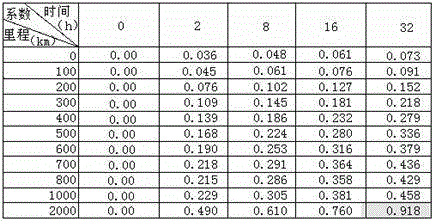

[0019] Table 1: Correspondence table of pressure difference and carbon loading

[0020] SOOT_INDEX SOOT_MASS 0.130 0.382.3 0.944.8 1.386.6 1.949.1 2.511.4 2.9413.4 3.4415.4 418.3 4.4421.6 5.0625.4 5.527.9 5.9430.2 6.5633.7 735.8 1260

[0021] In Table 1, SOOT_INDEX refers to the standard pressure drop coefficient produced only by carbon deposits, and SOOT_MASS refers to the weight of carbon deposits.

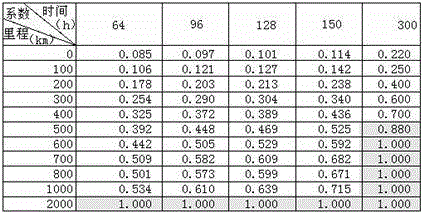

[0022] The estimated carbon load is divided into three ways, one is used for regular regeneration timing selection, the estimated carbon load is greater than the acceptable threshold (the maximum carbon load calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com