Reciprocating impact type excavator lubricating method and reciprocating impact type excavator lubricating system implementing method

A technology for lubrication systems and excavators, applied in the direction of engine lubrication, lubrication pumps, lubrication parts, etc., can solve the problems of no lubrication system, low block material rate, low efficiency, etc., and achieve flexible and adjustable installation positions and maintenance The effect of small quantity and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

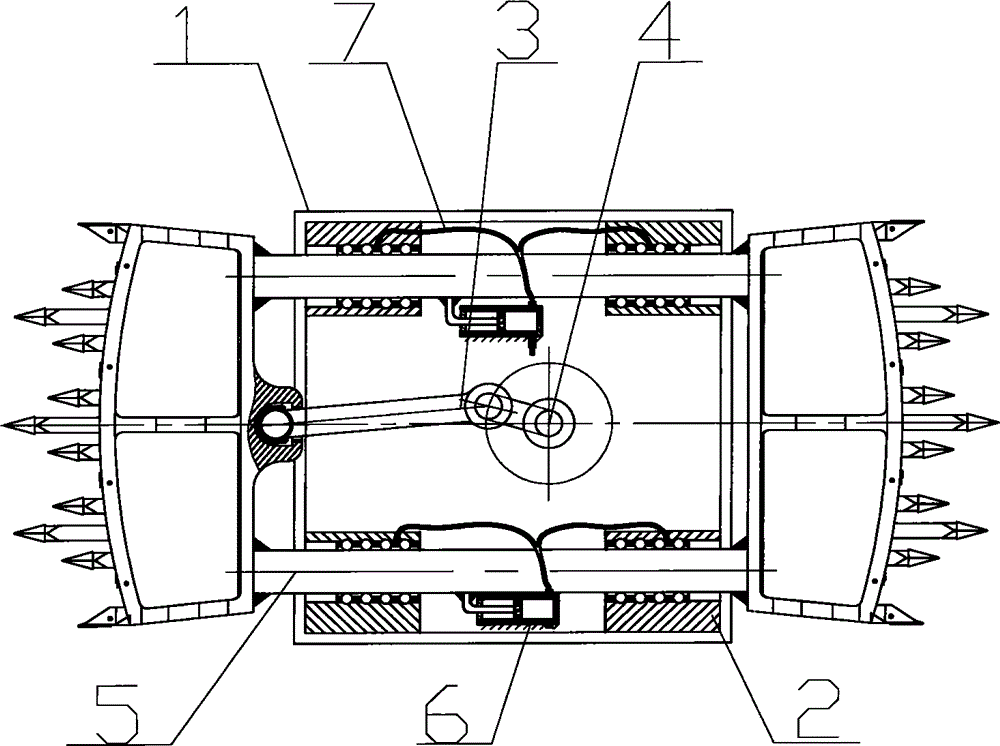

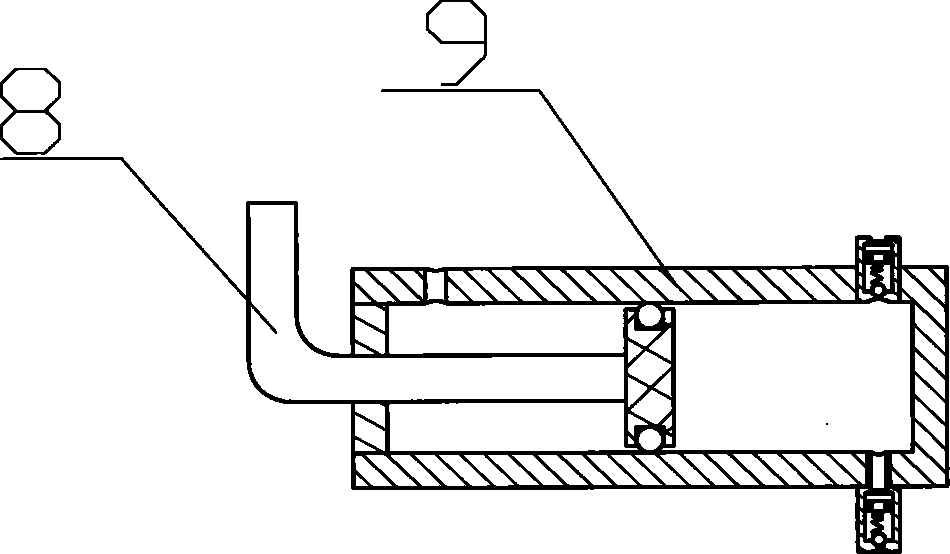

[0061] Figure 1 to Figure 2 It is the reciprocating impact mining machine lubrication system described in embodiment 1. The reciprocating impact mining machine lubrication system includes an impact power box 1, a pipeline 7 and a liquid suction pump lubrication device 6, etc., the liquid suction pump lubrication device 6 is arranged inside the impact power box 1, and the pipeline 7 and the liquid suction pump lubrication device 6 connection, the impact power box 1 includes the box body 2, the impact guide rod 5 and the power impact member 3, etc., the power impact member 3 drives the impact guide rod 5 to reciprocate, the liquid suction pump lubrication device 6 includes the plug rod 8 and the plug rod pump The cavity 9 is combined, etc. When the plug rod pump cavity 9 is fixed on the box body 2, the plug rod 8 that cooperates with it to reciprocate relatively is fixed on the impact guide rod 5, and the impact guide rod 5 drives the plug rod 8 and the plug rod. The relative ...

Embodiment 2

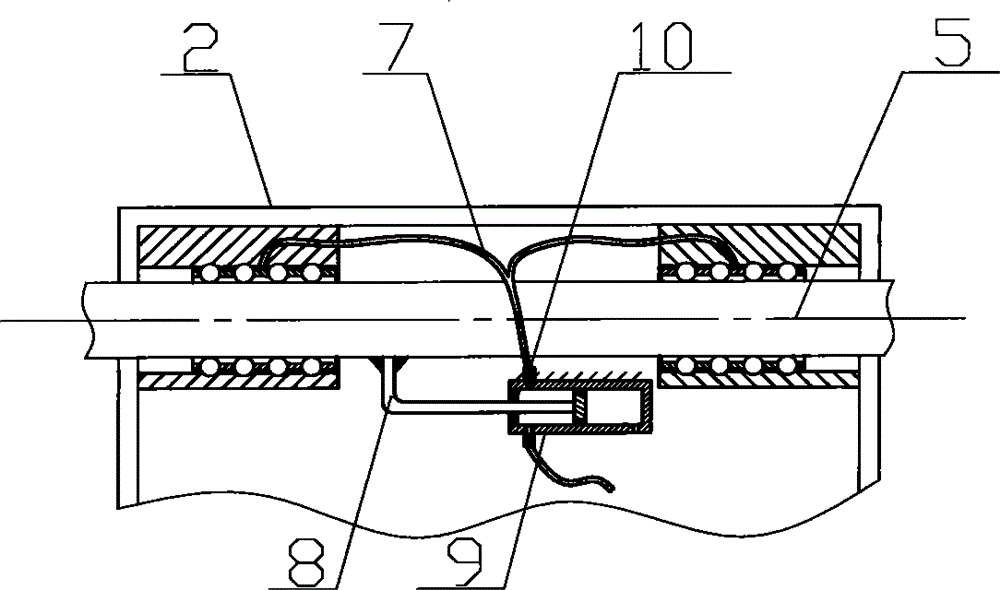

[0069] like image 3 As shown, it is the reciprocating impact type excavator lubrication system shown in Embodiment 2. The difference from Embodiment 1 is that the liquid suction pump lubrication device 6 includes a combination of a plug rod 8 and a plug rod pump cavity 9, etc., and the plug rod pump cavity The body 9 is fixed on the box body 2, and the plug rod 8 is connected with the impact guide rod 5. The impact guide rod 5 drives the plug rod 8 to reciprocate relative to the plug pump cavity 9, and a check valve 10 is provided at the liquid outlet 27 of the plug pump cavity 9, and the check valve 10 is connected with the pipeline 7, and the tube The outlet of Road 7 is connected to the part that needs to be lubricated.

[0070] Others are with embodiment 1.

Embodiment 3

[0072] like Figure 4 Shown is the reciprocating impact mining machine lubrication system shown in Embodiment 3, which is different from Embodiment 1 in that: the liquid suction pump lubrication device 6 includes a combination of a plug rod 8 and a plug rod pump cavity 9 and the like. The plug rod pump cavity 9 is fixed on the impact guide rod 5 and the plug rod 8 which cooperates with it to reciprocate relatively is fixed on the box body 2 .

[0073] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com