Cast aluminum heat exchanger of gas-fired boiler

A gas-fired boiler and heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of water inlet pipe and water outlet pipe assembly, high cost, large overall volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

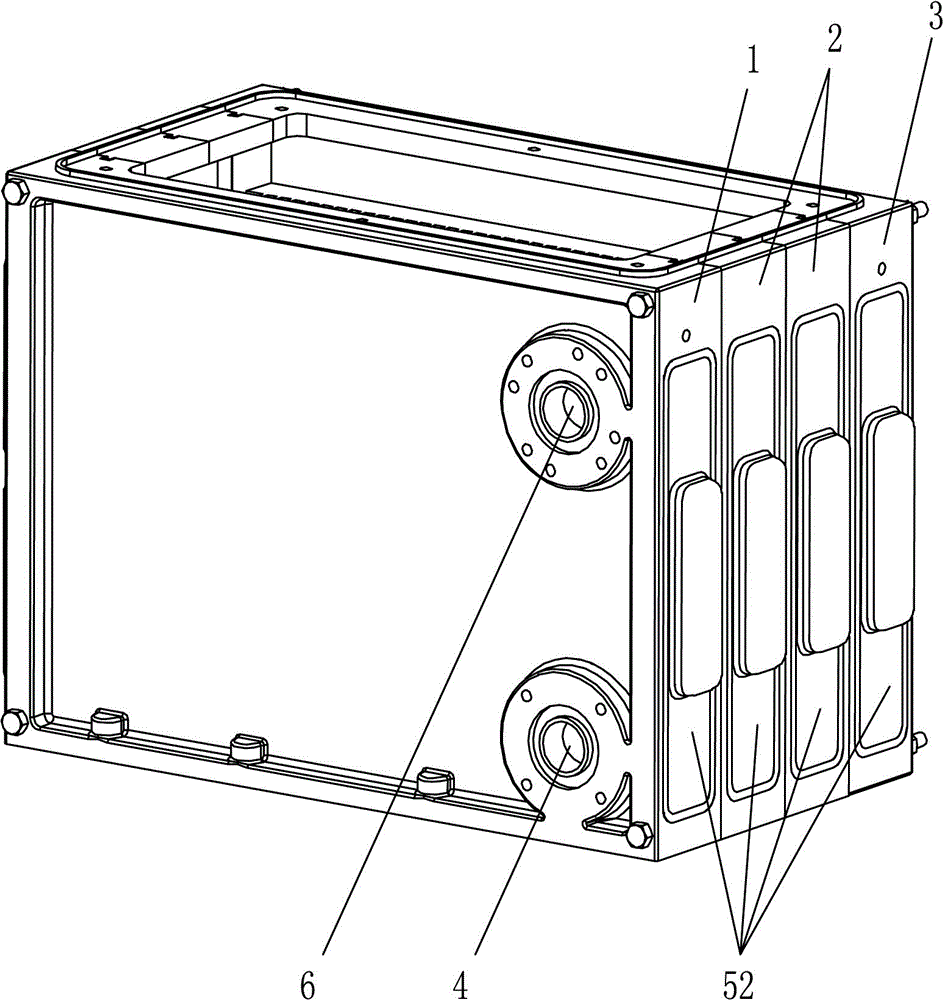

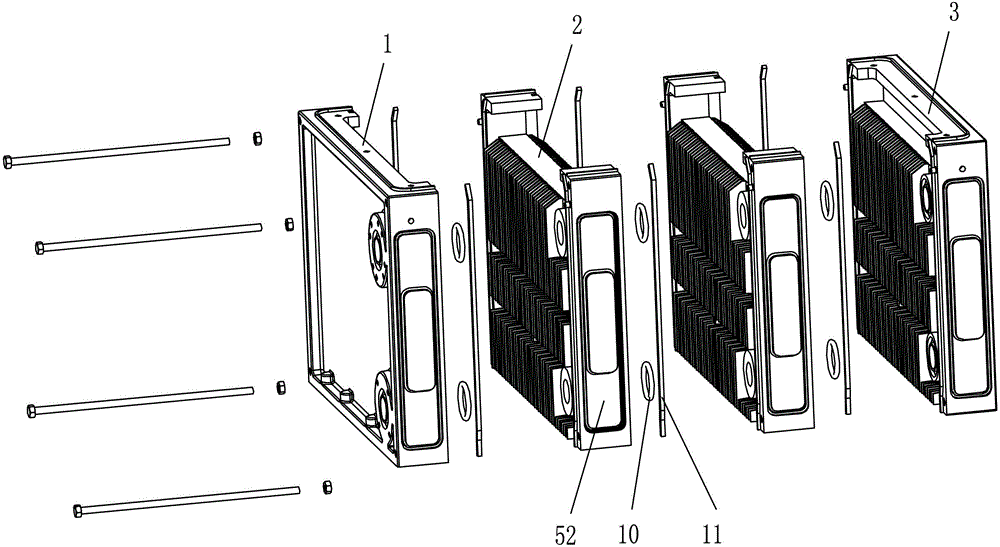

[0020] like Figure 1 to Figure 6 As shown, this embodiment includes a front module 1, a middle module 2 and a back module 3, four middle modules 2 are sandwiched between the front module 1 and the back module 3, and the front module 1, the middle module 2, and the back module 3 are all die-casted. , and are fastened together by bolts.

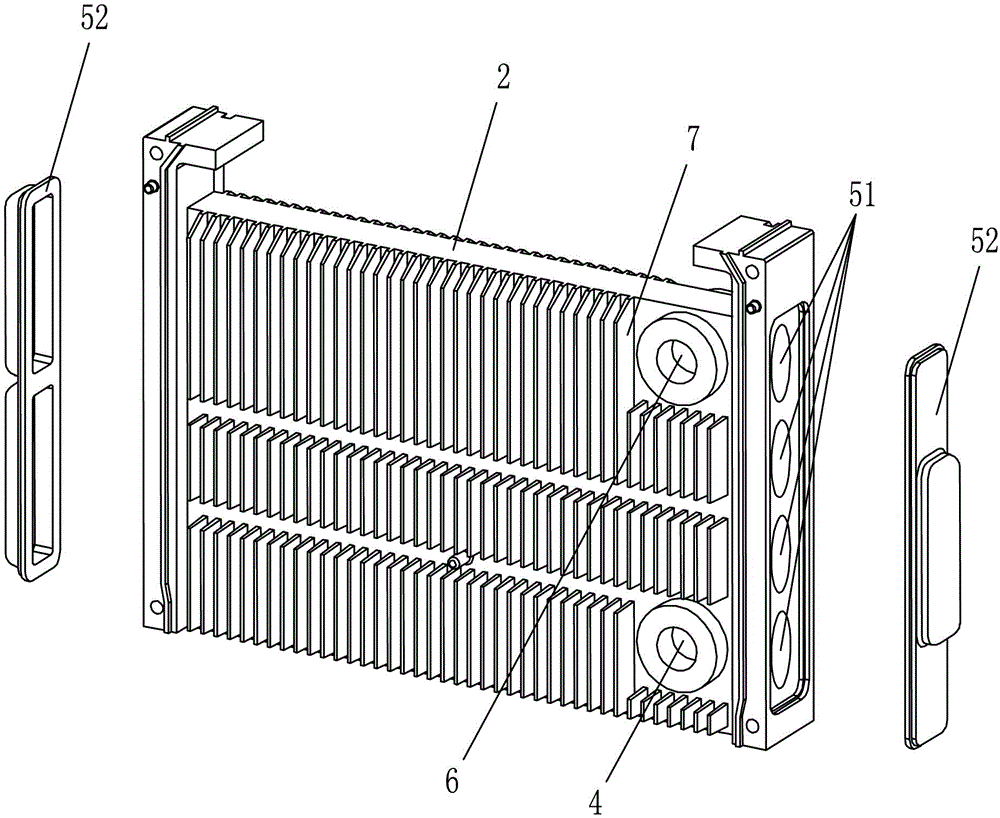

[0021] like figure 2 , image 3 , Figure 5 and Image 6 As shown, each module is provided with a water channel inside, and the water channel is composed of a main water inlet 4 , a water exchange channel 5 and a main water outlet 6 . The water exchange channel 5 in each module is connected with the total water inlet 4 and the total outlet 6, the total water inlet 4 of the adjacent modules is connected, the total outlet 6 of the adjacent modules is connected, and there are water channels between adjacent modules sealing ring 10. The total water inlet 4 is linearly arranged at the lower part of the module, the total water outlet 6 is lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com