Heat pipe radiator integrated with heat transmission and heat radiation and manufacturing technology thereof

A technology of heat pipe radiator and manufacturing process, which is applied to indirect heat exchangers, lighting and heating equipment, etc. It can solve the problems of increasing the weight and volume of heat dissipation products and reducing heat conduction efficiency, and achieves high heat dissipation efficiency and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

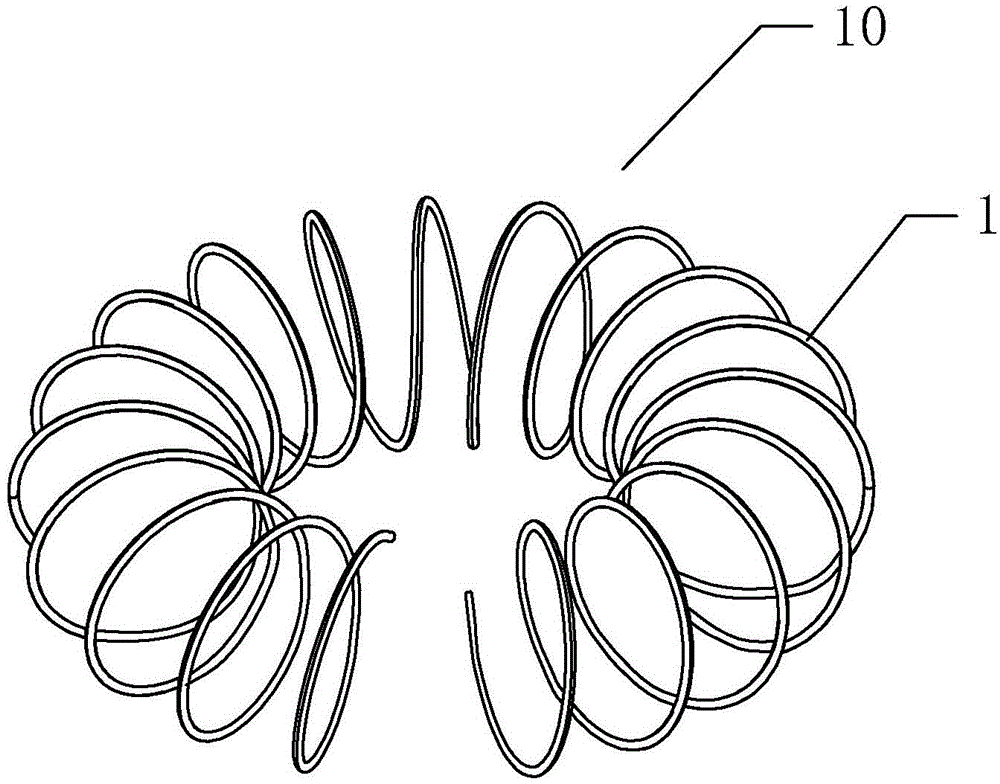

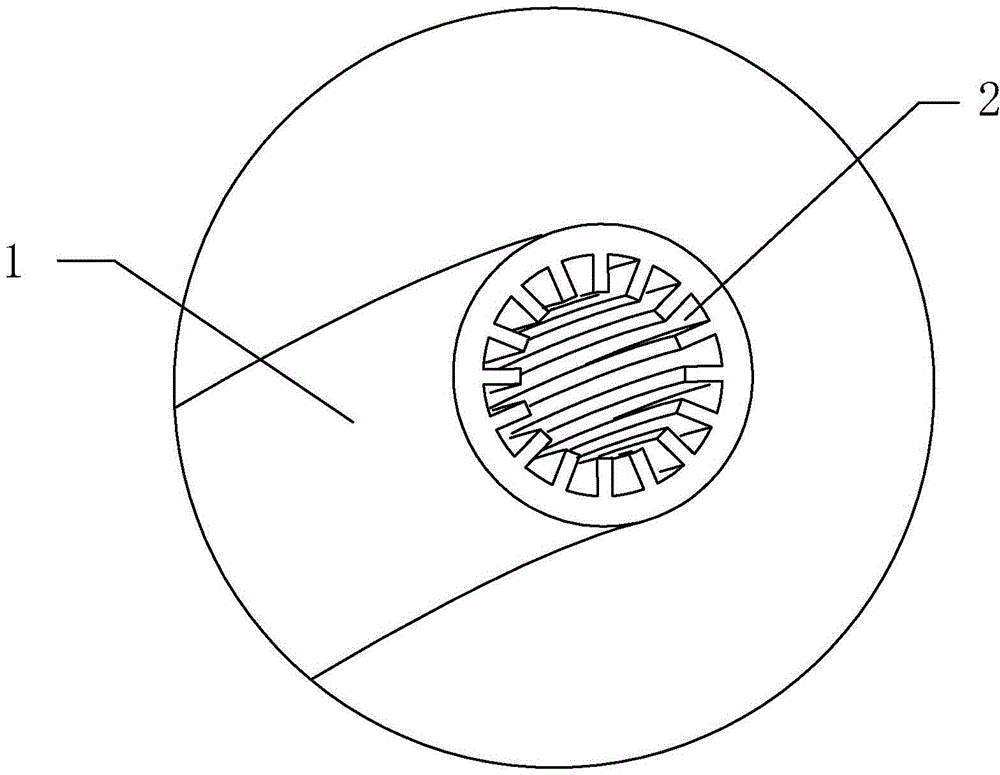

[0030] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a heat pipe radiator integrating heat transfer and heat dissipation includes a heat pipe radiator main body 10, and the heat pipe radiator main body 10 includes a heat pipe 1 coiled into a spiral structure , the inner wall of the heat pipe 1 is axially provided with several grooves 2, and the diameter of the heat pipe 1 is selected from 2 mm to 5 mm. In this embodiment, the main body 10 of the heat pipe radiator is bent into an annular structure. Among them, the heat pipe radiator main body 10 can also be bent into a square, oval, drop-shaped or other irregular shapes according to the shape of the required heat dissipation product.

[0031] The manufacturing process of the heat pipe radiator integrating heat transfer and heat dissipation of the present invention can be realized through the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com