Device and method for measuring surface temperature of plate blank online

A surface temperature and slab technology, which is applied in the field of devices for online measurement of slab surface temperature, can solve the problems of inaccurate temperature measurement data, difficulty in detecting the surface temperature of casting slab, and inability to uniformly reflect temperature changes, etc. The effect of temperature accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

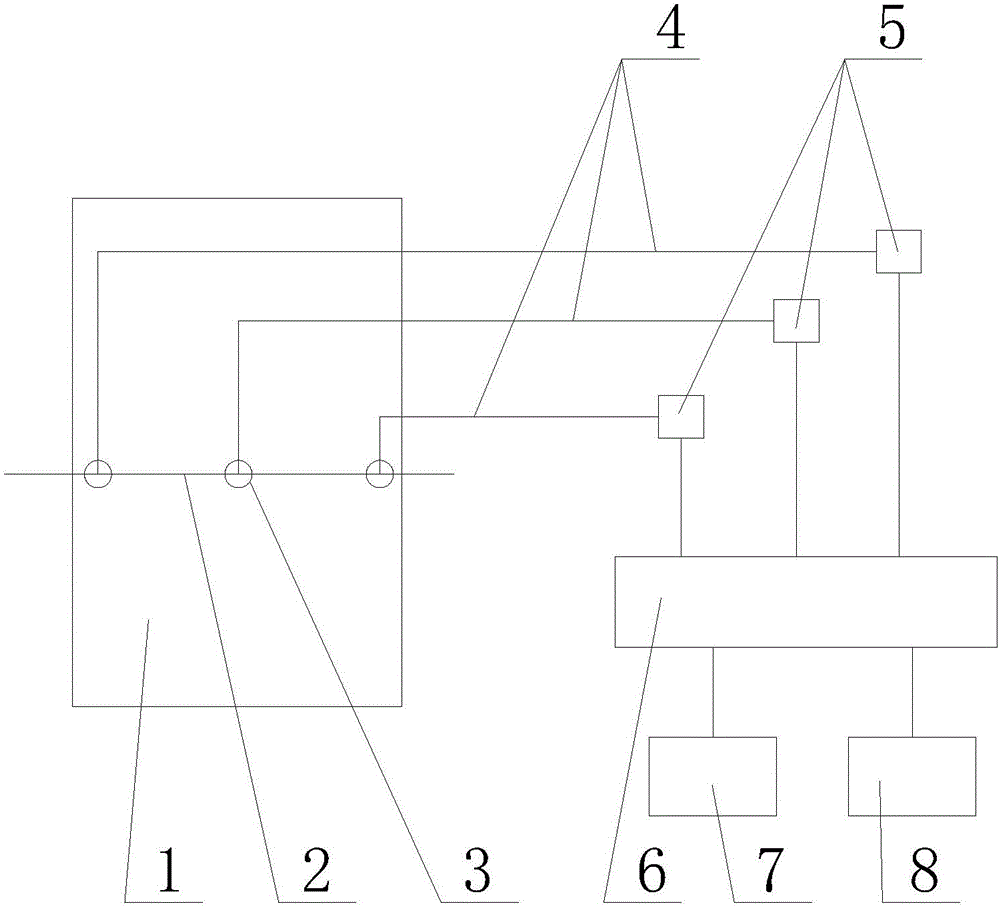

[0044] A device for online measurement of slab surface temperature provided by the present invention includes:

[0045] Temperature measuring components, fixed components.

[0046] The temperature measuring component is placed in the segment of the secondary cooling zone of the slab 1 through the fixing component.

[0047] The temperature measurement components include: a temperature measurement probe, a temperature measurement optical fiber and a metal hose 4 .

[0048] The temperature measuring probe is arranged at the head of the temperature measuring optical fiber; the temperature measuring optical fiber is placed in the metal hose 4 .

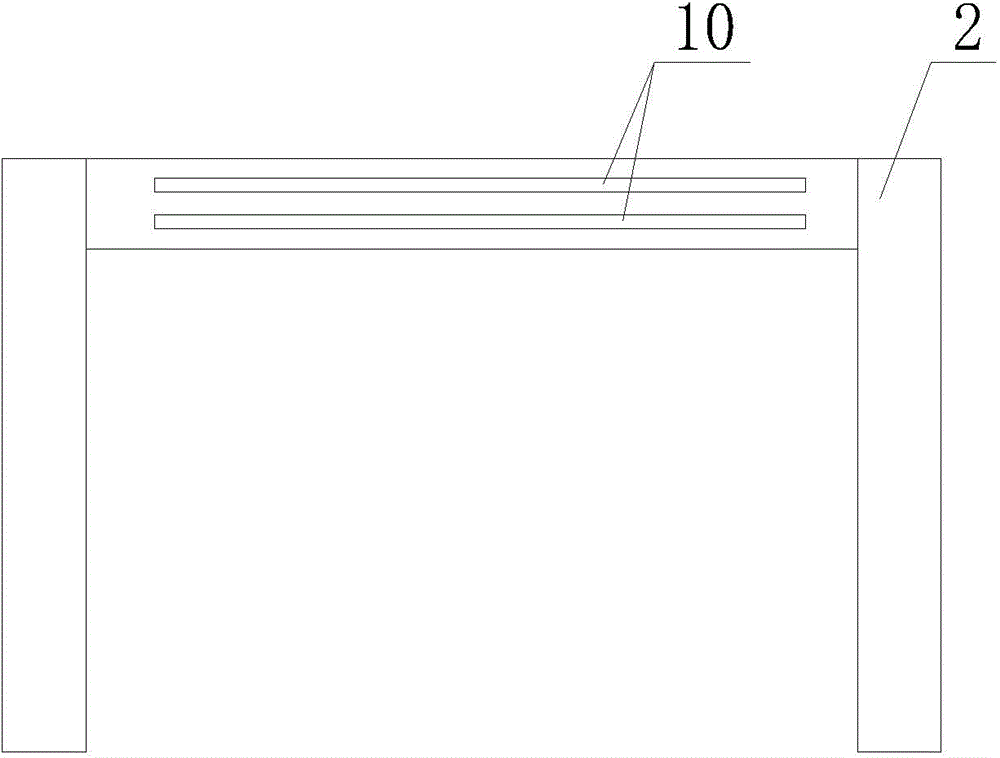

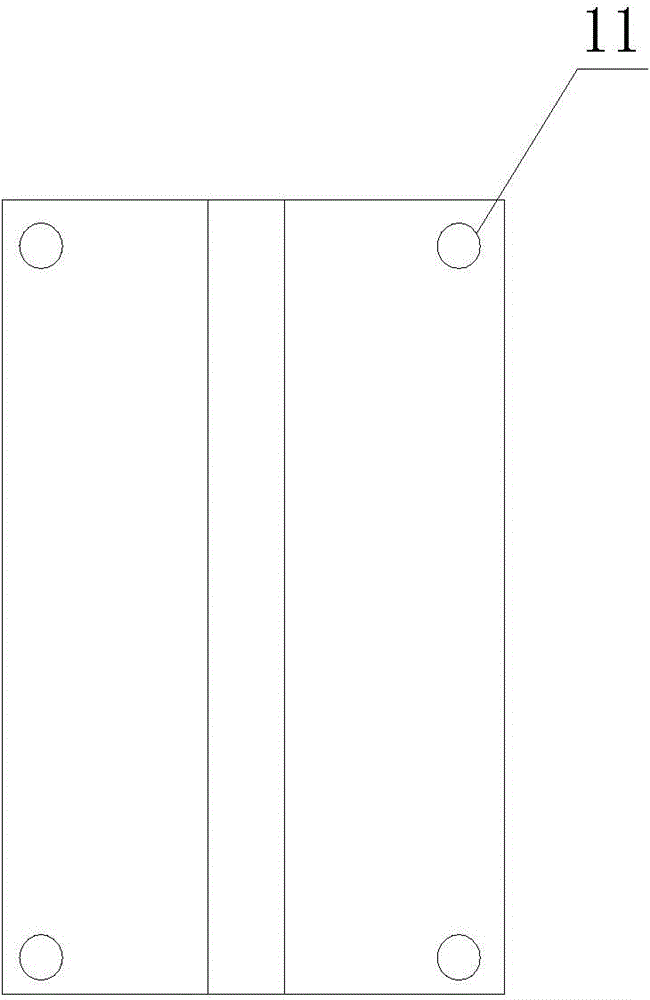

[0049] The fixing component includes: a probe fixing frame 2 , a connecting piece 9 and a probe protection sleeve 3 .

[0050] The connecting piece 9 is movably connected with the probe fixing frame 2; the probe protective sleeve 3 is fixedly connected with the connecting piece 9.

[0051] Among them, the temperature measuring probe is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com