Civil engineering material deformation experimental instrument suitable for multipoint measurement

A material deformation, multi-point measurement technology, applied in the direction of material thermal expansion coefficient, mechanical solid deformation measurement, etc., can solve the problems of inability to obtain experimental results, insufficient height, falling off, etc., to achieve the effect of maintaining experimental conditions, convenient measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

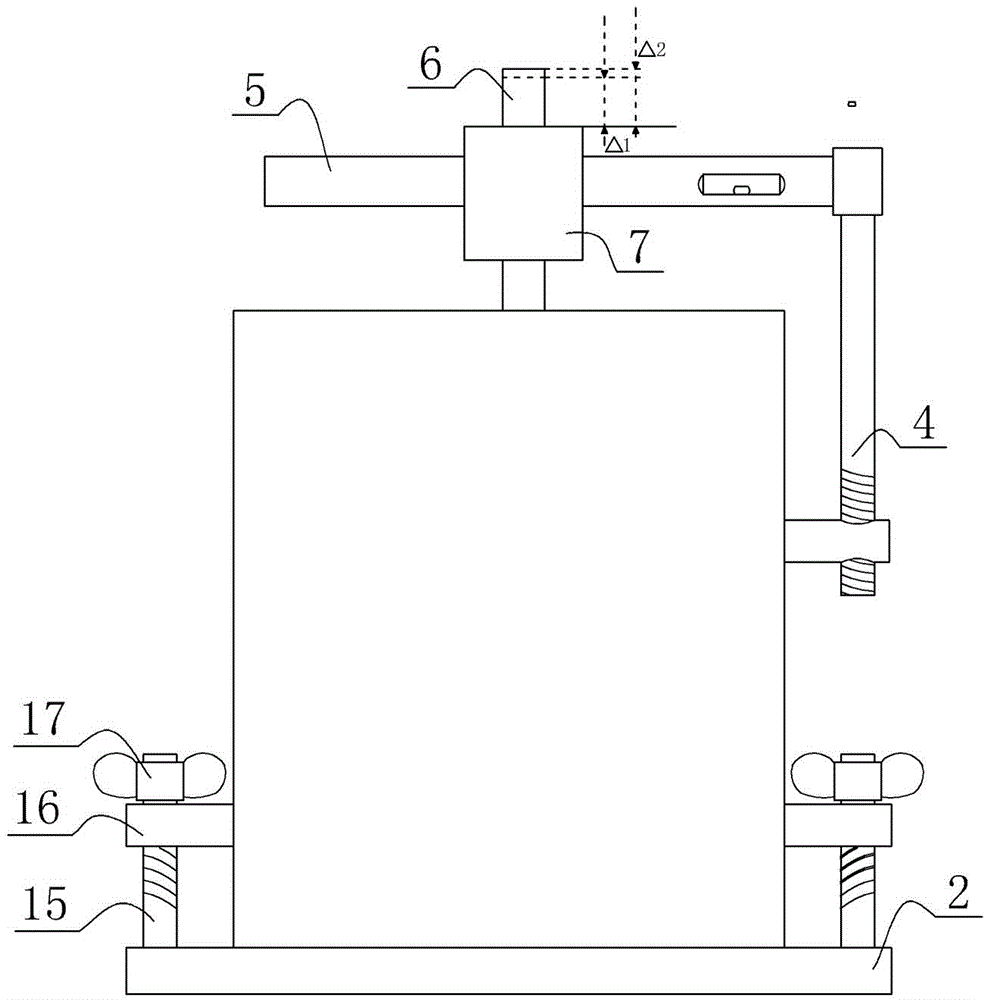

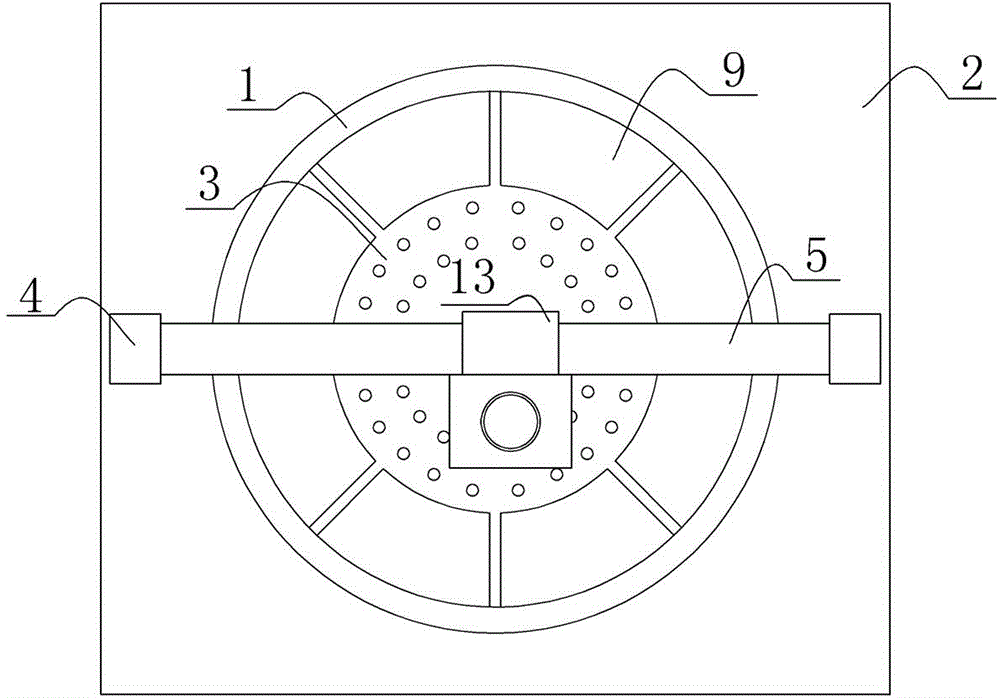

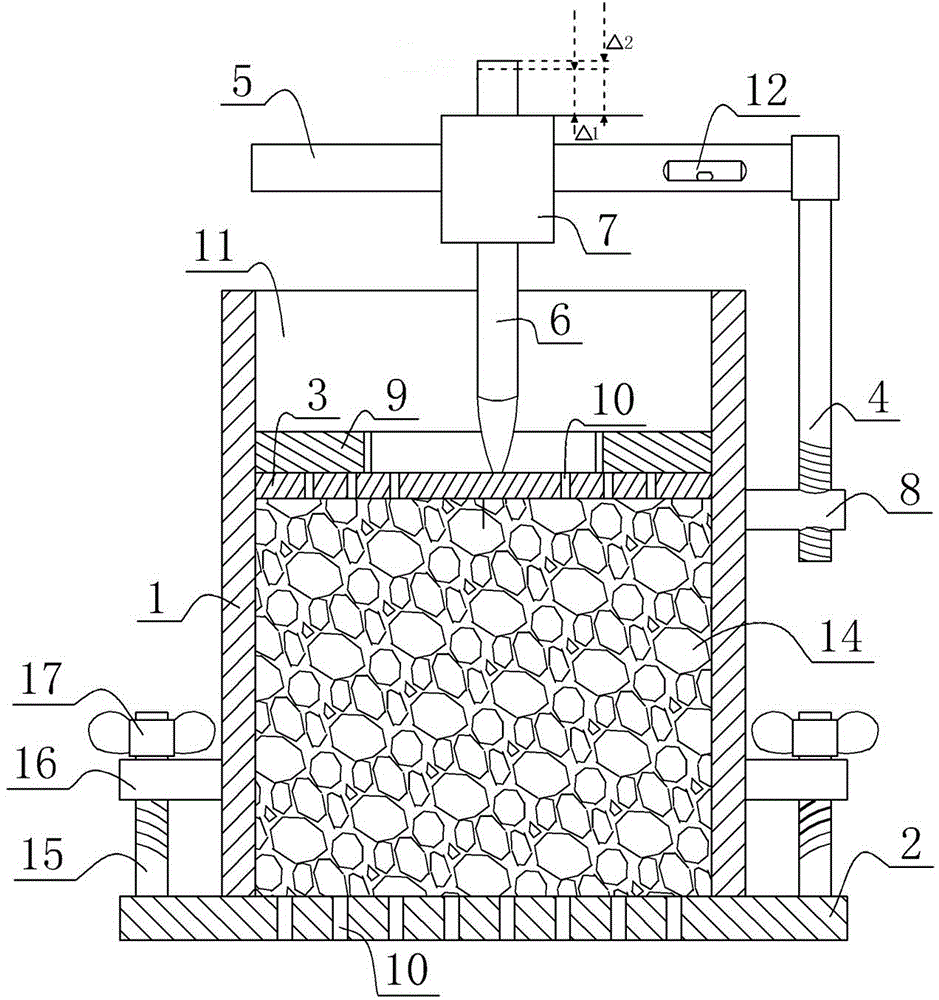

[0016] Such as figure 1 , figure 2 with image 3 As shown, the front view, top view and cross-sectional view of the civil material deformation tester of the present invention are provided, which include a metal cylinder 1, a lower perforated plate 2, an upper perforated plate 3, a supporting vertical beam 4, a supporting beam 5, and a contact rod 6. Spring contacts 7, support rods 8; the inside of the metal cylinder 1 shown is a cylindrical cavity 11 for holding experimental materials 14, the lower perforated plate 2 is fixed on the lower part of the metal cylinder 1, and the upper perforated plate 3 is set On the top of the experimental material 8, the upper perforated plate 3 and the lower perforated plate 2 are provided with a plurality of through holes 10. Due to the existence of the through holes 10, it is convenient for moisture and heat to ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com