Oil-oil bushing cable outlet transformer test method without head removing

A test method and cable outlet technology, applied in the field of transformers, can solve problems such as failure to perform normally and inconvenient disassembly of transformers, and achieve the effects of ensuring safety, reducing equipment power outage time, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

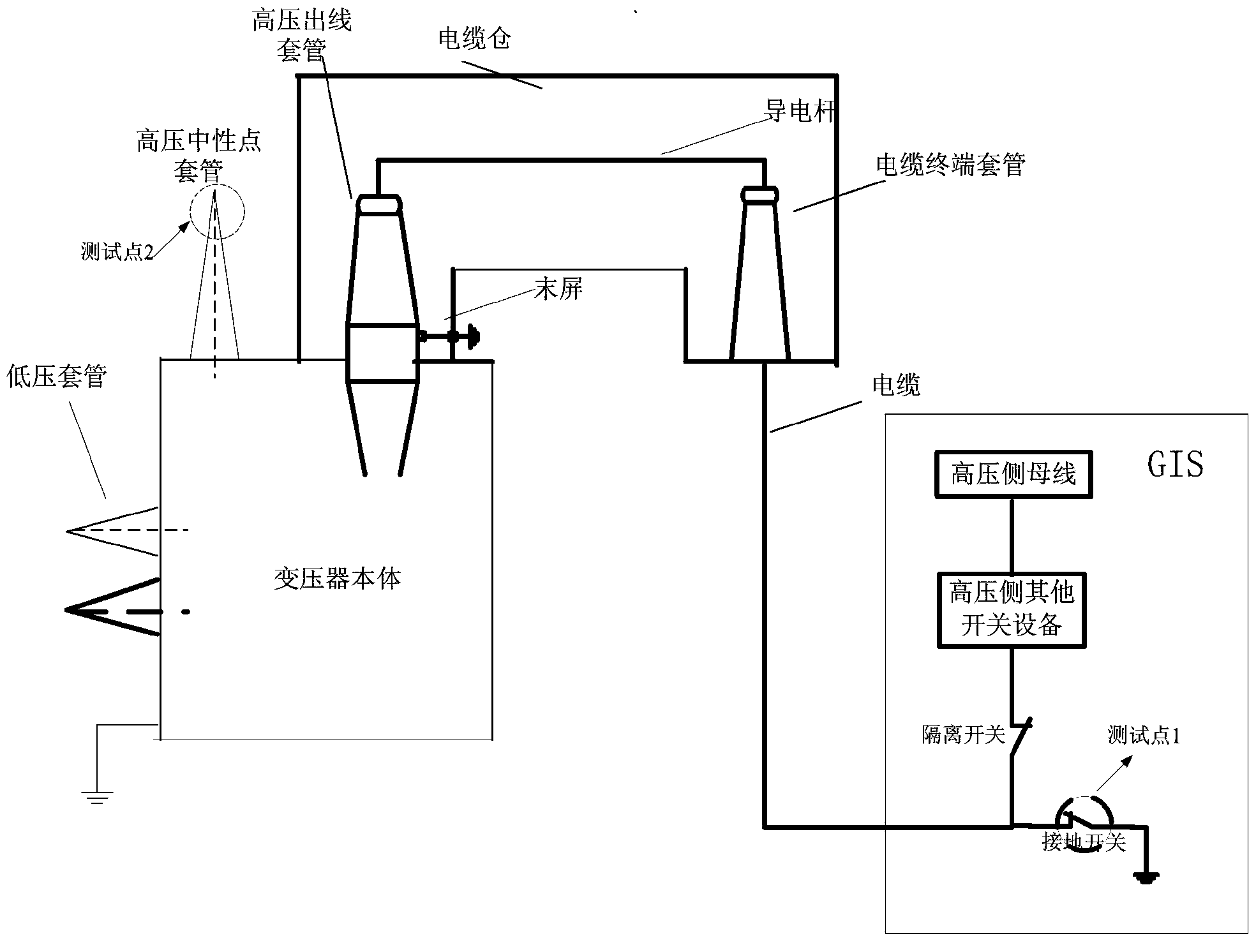

[0014] A test method for oil-oil bushing cable outlet transformer without removing the head, such as figure 1 shown, including the following steps:

[0015] Step 1. Perform the DC resistance test on the high voltage side: disconnect the isolating switch on the high voltage side busbar, close the grounding switch, open the grounding connection piece, and use a DC resistance tester at the grounding switch (test point 1) to conduct a DC resistance test on the high voltage side .

[0016] In this embodiment, a three-phase double-winding transformer is taken as an example, wherein the high-voltage side of the transformer adopts an oil-and-oil bushing cable outlet type.

[0017] Step 2. Carry out the insulation resistance, absorption ratio and polarization index test of the high-voltage side to the low-voltage side: restore the grounding connection piece, turn on the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com