Connector

A technology of connectors and pins, which is applied to contact parts, parts of connecting devices, connections, etc., can solve the problems of undisclosed one-time stamping and deep drawing technology, and can not process connectors, etc., to improve strength and rigidity , convenient processing, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

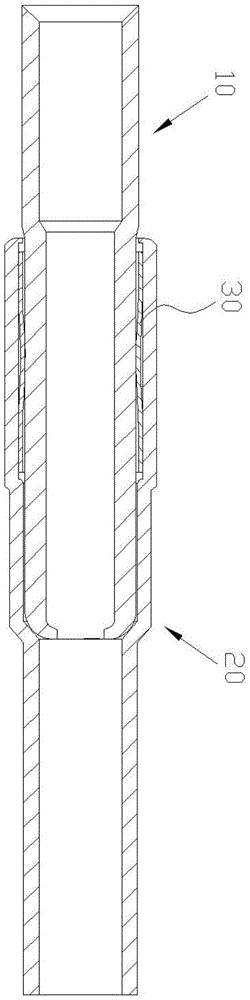

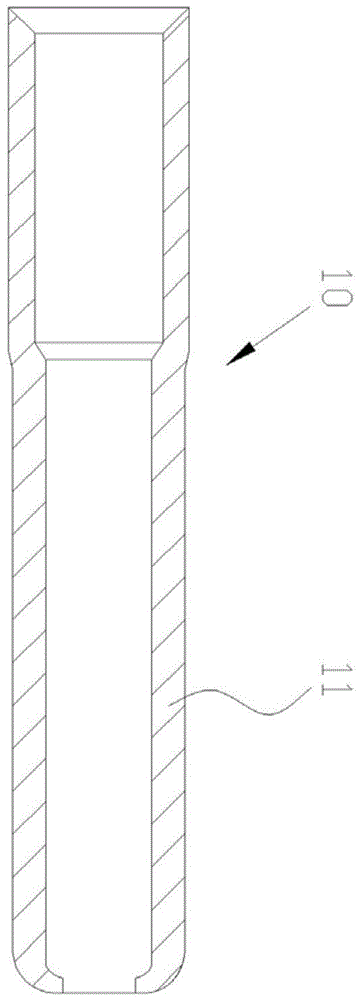

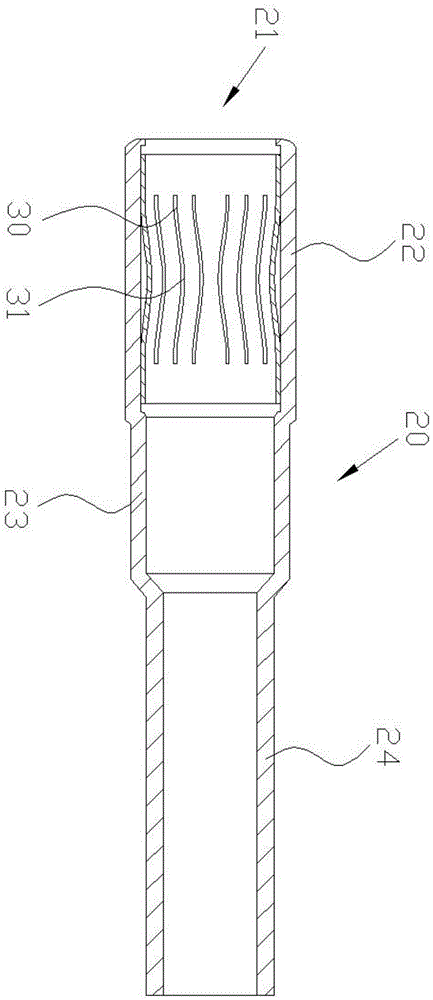

[0022] Such as Figure 1 ~ Figure 4 As shown, a connector of the present invention includes a hollow pin 10 inside and a sleeve 20 used in conjunction with the pin 10. The pin 10 is provided with a rod 11, and the sleeve 20 is An insertion hole 21 is provided, and the pin 10 is formed by one-time stamping and deep drawing of a brass sheet material. The ratio of the diameter of the pin 10 to the diameter of the brass sheet material is greater than that of the brass sheet material. The ultimate drawing coefficient of the material. As a further improvement of the present invention, the pin 10 may be stepped. At this time, the ratio of the smallest step diameter to the diameter of the brass sheet material is greater than the limit drawing coefficient of the brass sheet material. Wherein, the brass sheet material may be H62 brass or H68 brass. The ultimate drawing coefficient of H62 brass is 0.52~0.54, and the limiting drawing coefficient of H68 brass is 0.50~0.52. When the relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com