A camera resolution test device and method

A test device and camera technology, applied in image communication, television, electrical components, etc., can solve problems such as inaccurate test results, inability to adjust, and decreased contrast of black and white stripes, so as to avoid inhomogeneity of emitted light and avoid inaccuracy factors, the effect of test results being accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

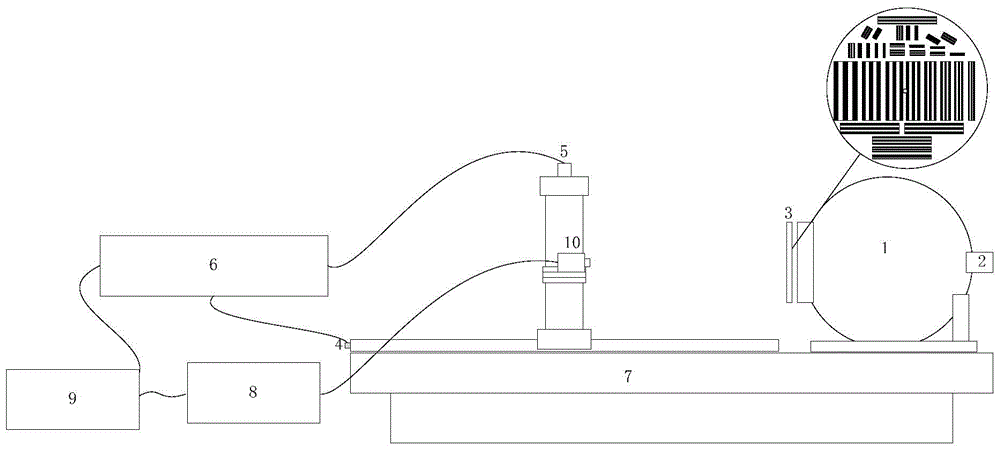

[0038] In order to achieve accurate testing of the camera resolution, the present invention uses a large field of view integrating sphere to achieve light source output, and a transmissive multi-group fringe discrimination rate board is placed at the light exit of the integrating sphere, and the camera is fixed on a long guide rail. Adjust the camera distance, use the computer to collect the output image of the camera and determine the narrowest stripe width that the camera can distinguish, so as to realize the accurate test of the resolution of the camera under any output format at a certain focal length and a certain camera distance.

[0039] Attached below figure 1 , The device of the present invention is described in detail:

[0040] A camera resolution test device, comprising an optical stabilization platform 7, an image acquisition unit 8, a computer 9, and a large field of view integrating sphere 1, an integrating sphere light source 2, and a transmissive multi-group fringe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com