Resin composition for display substrates

A technology of resin composition and display, applied in the direction of instruments, coatings, optics, etc., can solve the problems of not having low linear expansion characteristics, expensive products, lack of versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

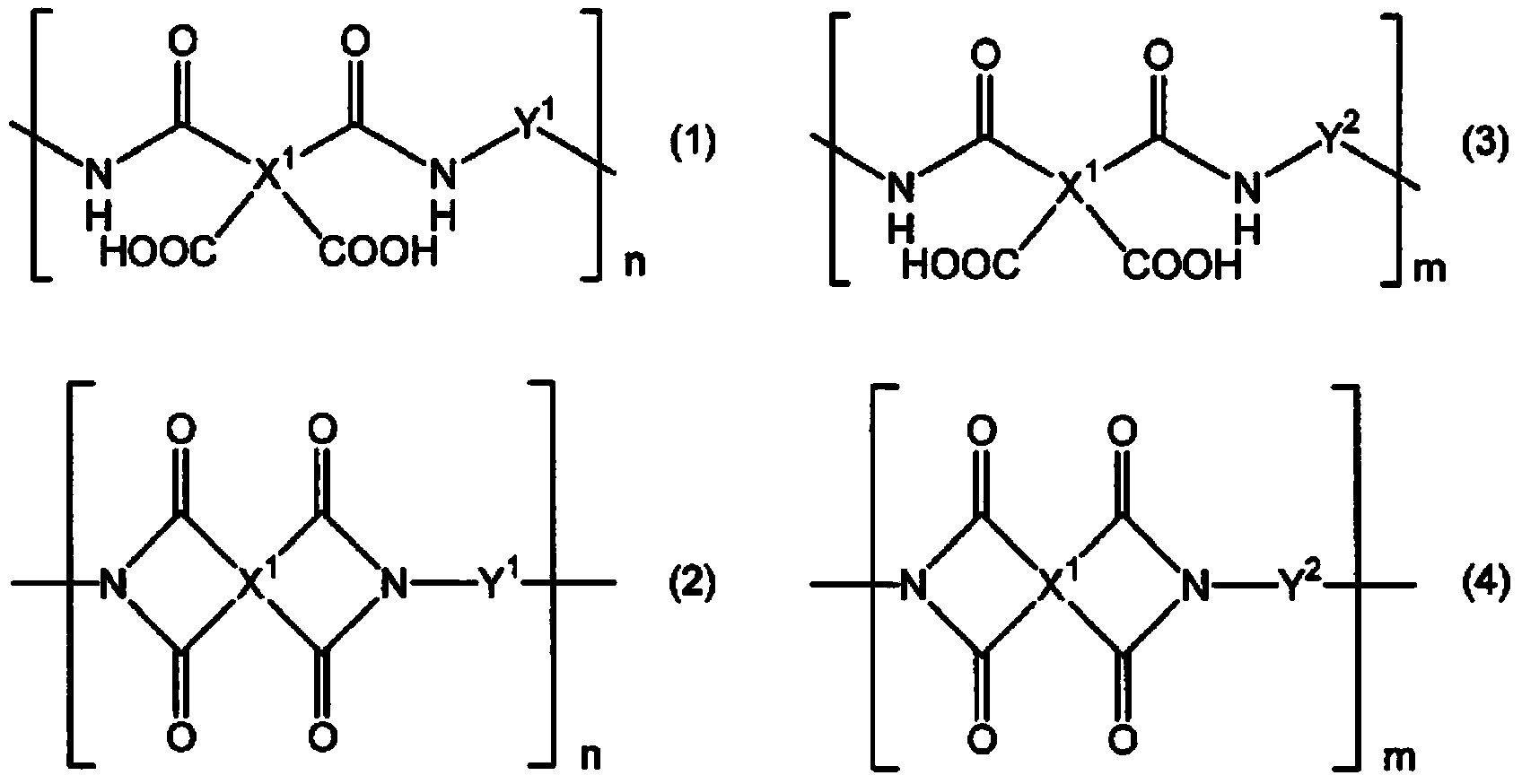

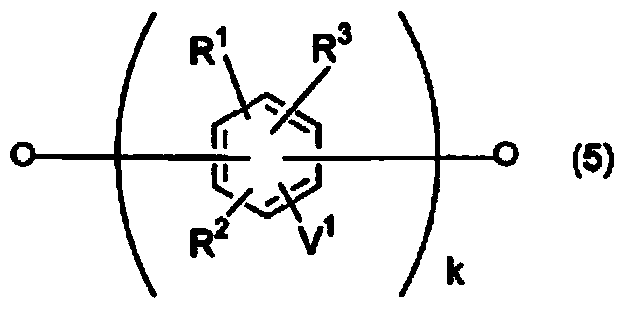

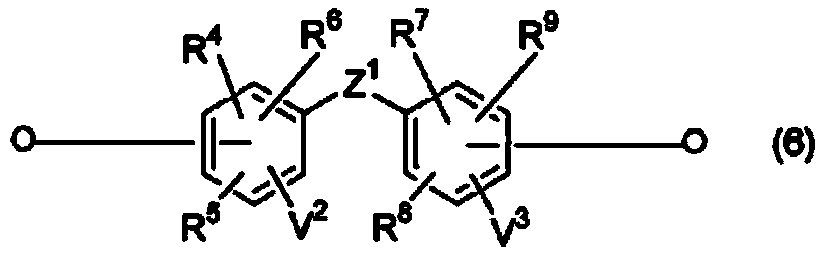

Method used

Image

Examples

Embodiment

[0214] Examples are given below to describe the present invention more specifically, but the present invention is not limited to the following examples.

[0215] [Abbreviated symbols used in Examples]

[0216] The meanings of the abbreviations used in the following examples are as follows.

[0217]

[0218] BP-TME: 4,4'-biphenyl bis(trimellitic acid monoester anhydride) (manufactured by Honshu Chemical Industry Co., Ltd.) (the following formula (12))

[0219] [chemical 19]

[0220]

[0221] TAHQ: p-phenylene bis(trimellitic acid monoester anhydride) (manufactured by Manac Co., Ltd.) (the following formula (13))

[0222] [chemical 20]

[0223]

[0224]

[0225] PDA: p-phenylenediamine (manufactured by Tokyo Chemical Industry Co., Ltd.)

[0226] HAB: 4,4'-diamino-3,3'-dihydroxybiphenyl (manufactured by Wakayama Seika Kogyo Co., Ltd.)

[0227] 4BP: 3,3'-diamino-4,4'-dihydroxybiphenyl (manufactured by Wakayama Seika Kogyo Co., Ltd.)

[0228]

[0229] V8000-C7: Na...

Synthetic example P1

[0234]

[0235] The PDA (0.154 mole) of 16.7g and the HAB (0.039 mole) of 8.34g are dissolved in the NMP of 700g, and the BP-TME (0.189 mole) of 101g is added, then the NMP of 74g is added again, under nitrogen atmosphere, make It was reacted at 23°C for 24 hours. The Mw of the obtained polymer was 129,000, and the molecular weight distribution was 2.5.

Synthetic example P2

[0236]

[0237] The PDA (0.156 mole) of 19.1g and the 4BP (0.039 mole) of 4.24g are dissolved in the NMP of 700g, and the BP-TME (0.192 mole) of 102g is added, then the NMP of 74g is added again, under nitrogen atmosphere, make It was reacted at 23°C for 24 hours. The Mw of the obtained polymer was 136300, and the molecular weight distribution was 2.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com