squeeze water mop

A mop and mop rod technology, applied in the field of mops, can solve the problems of damage, some of which break within a month or two, limited tensile and bending strength of plastic parts, large volume and weight of the mop head, etc., to overcome weather resistance Poor performance, good positioning and guiding effect, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

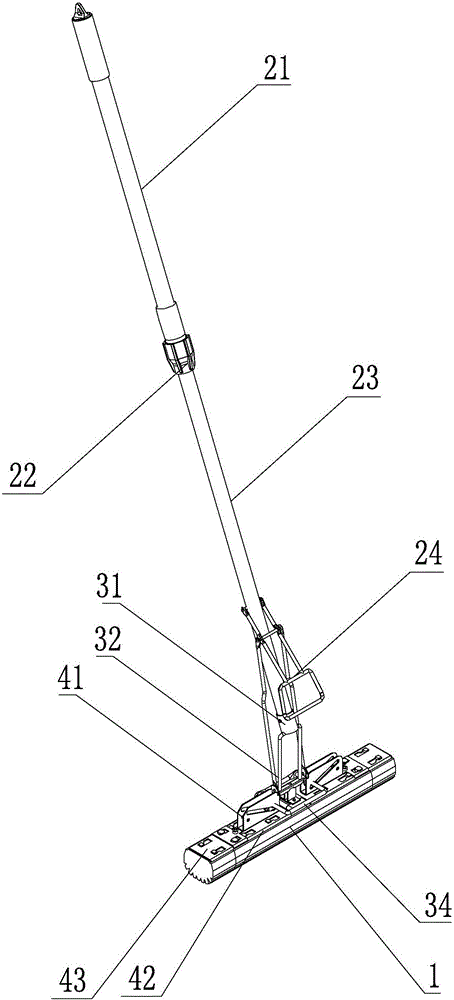

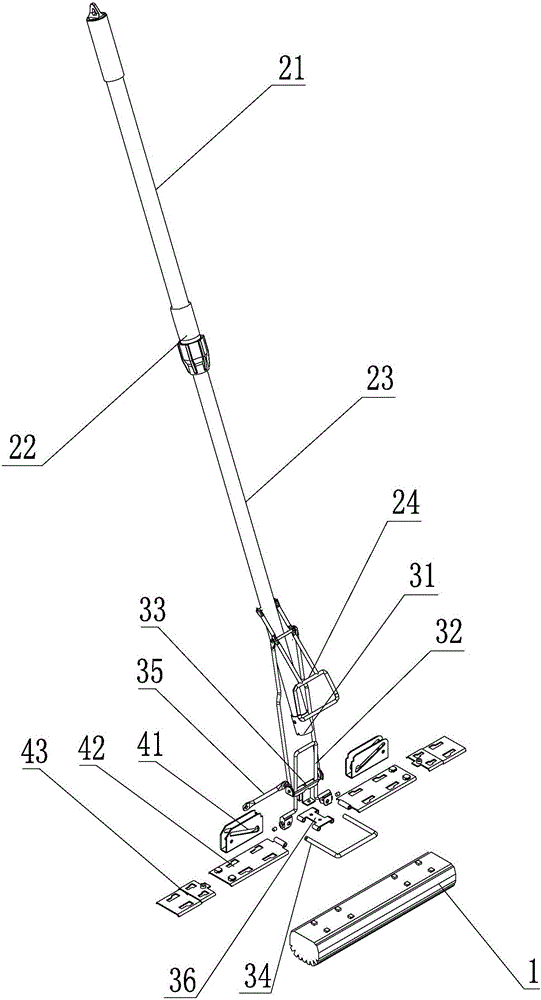

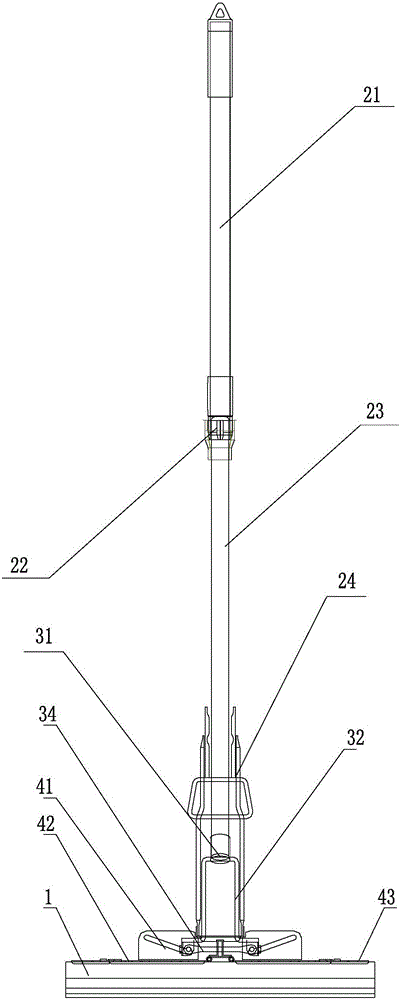

[0035] The squeeze mop of the present embodiment is as figure 1 , figure 2 and image 3 As shown, it includes a mop head 1 and a mop rod, wherein the mop head 1 is a strip made of collodion, and the mop rod is relatively fixed by the upper rod body 21 and the lower rod body 23 that are nested with each other through the bundle sleeve 22 . A fixed sleeve 31 is installed at the bottom of the lower rod body 23, and a main frame 32 formed by bending a metal bar is welded on the fixed sleeve 31. The main frame 32 is door-shaped and has a beam and two columns, wherein the beam and the fixed sleeve 31 welding, the bottom of the column is welded with a pair of sliders, the column is covered with a sliding sleeve 33, the two sides of the sliding sleeve 33 are connected to the handle 24 on the mop rod through the pull rod, and the bottom of the sliding sleeve 33 is fixedly connected with the center plate 36 A pair of splints 42 are hinged on both sides of the center plate 36, the mop...

Embodiment 2

[0041] The squeeze mop of the present embodiment is as Figure 6 , Figure 7 and Figure 8 As shown, it includes a mop head 1 and a mop rod 2, wherein the mop head 1 is a strip made of collodion. There is a handle 21 at the bottom of the mop rod 2, and a main frame 32 is installed at the bottom end of the mop rod. The main frame 32 is punched into a door shape by sheet metal, and has two uprights and a crossbeam on the top. Sleeved on the bottom end of the mop rod 2. The top plate of the beam is provided with a guide hole for passing through the pull rod 33 , and the bottom end of the pull rod 33 is fixedly connected with the central plate 35 and the cover plate 34 . A pair of splints 42 are hinged on both sides of the center plate 35. The mop head 1 is clamped under the splint 42. The back of the splint 42 is welded with a chute seat 41. The chute seat 41 has two parallel vertical plates. Between, and slidingly match with the chute on the vertical plate through the pin s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com