Laser spot welding monitoring method and monitoring device

A laser spot welding and spot welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high cost and inability to fully reflect the quality of laser spot welding, and achieve the effect of fast speed and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

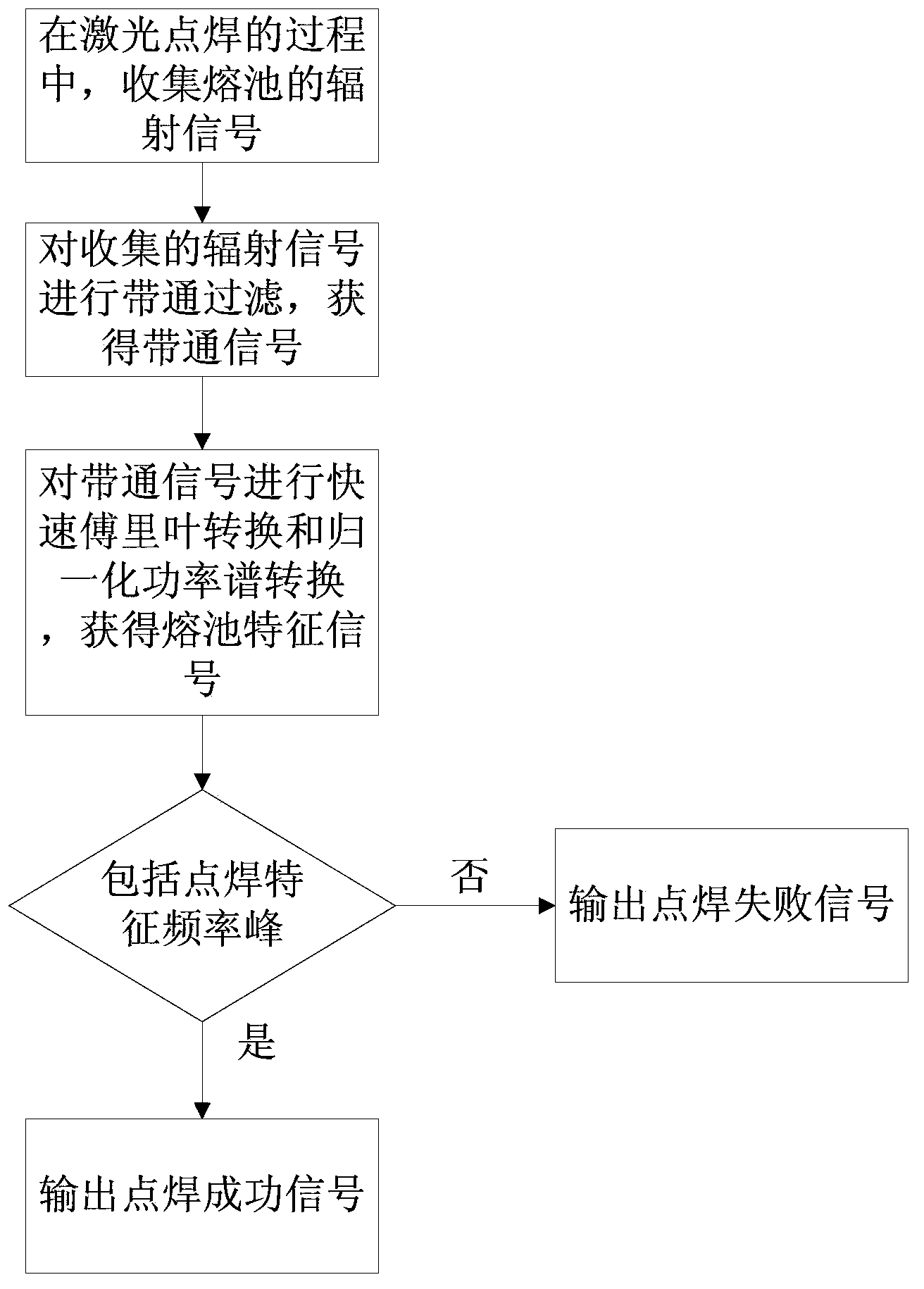

[0055] figure 1 , Fig. 2 is the working flow diagram of the laser spot welding monitoring method of the present invention, respectively corresponding to the monitoring in the spot welding process and the monitoring after the spot welding ends. It should be noted that the monitoring during the spot welding process and the monitoring after the spot welding only represent the time when the two monitoring signals are generated. In actual work, the two monitoring methods are carried out synchronously with the entire spot welding.

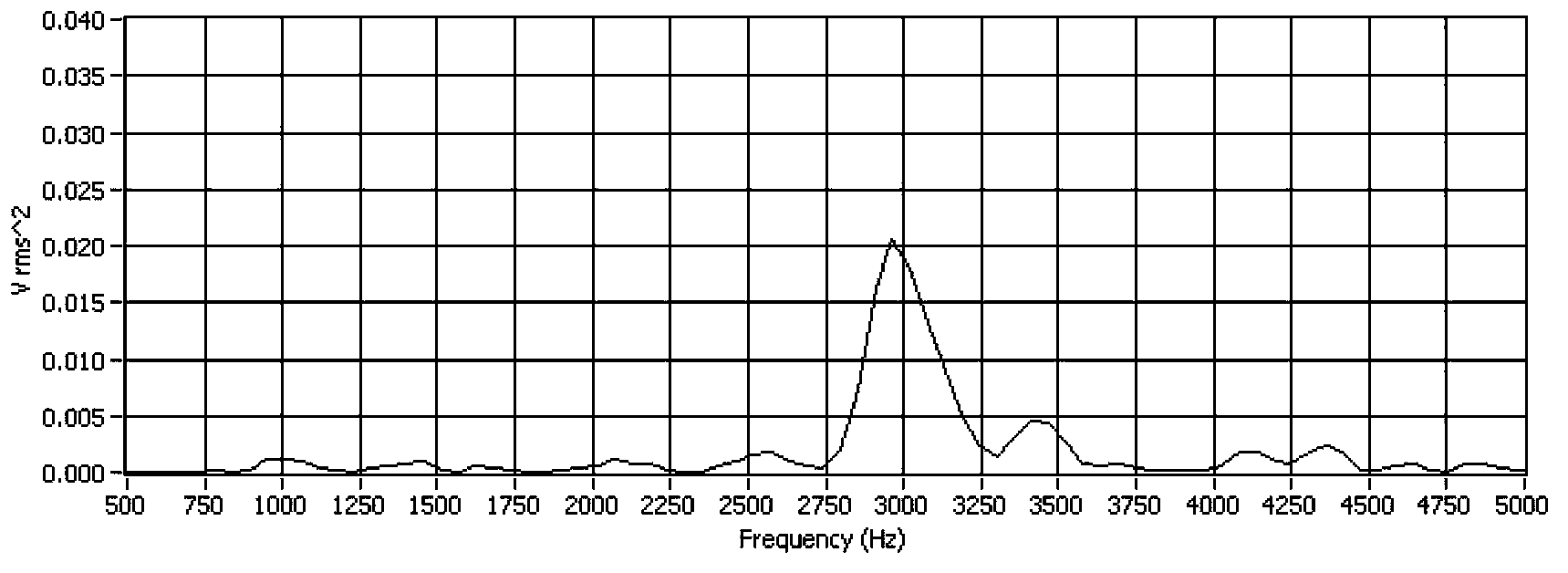

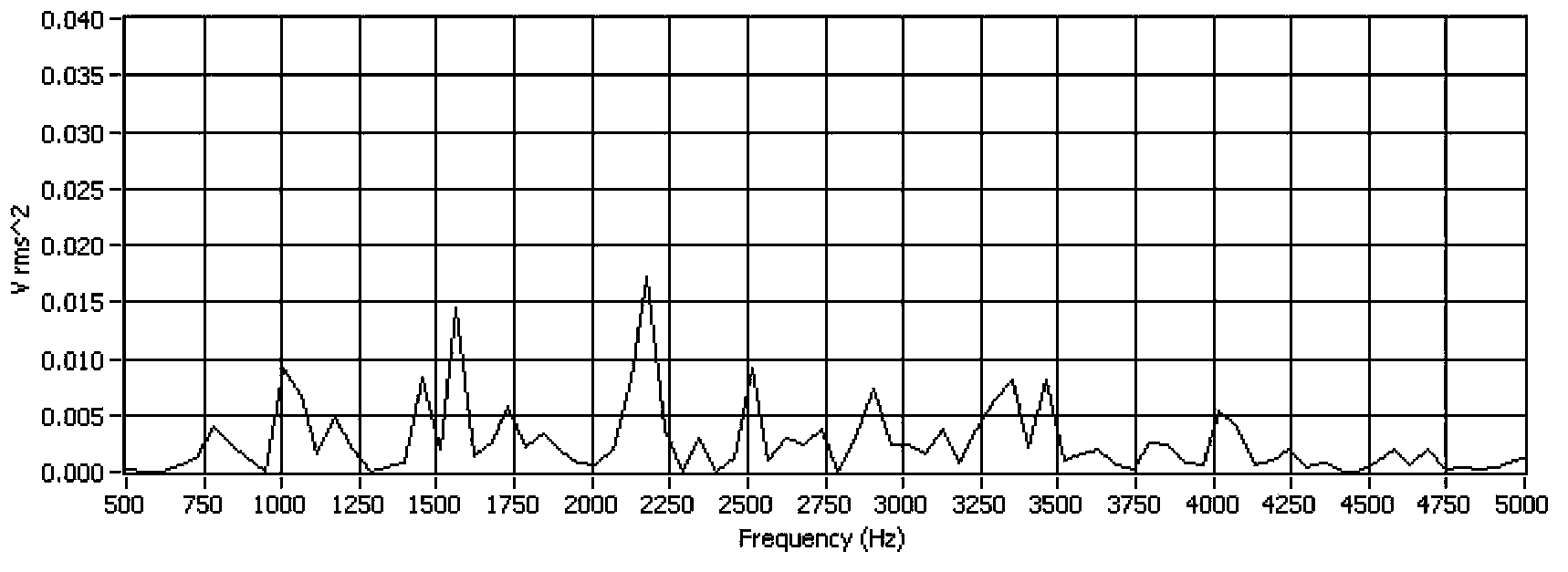

[0056] figure 1 It is a flow chart of monitoring during spot welding. When laser spot welding is working, a strong laser is irradiated on the welding sample to generate a molten pool, and signals will be radiated from the molten pool. The present invention first collects these radiated signals, band-pass filters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com