Bus frame structure of full-carrying type pure electric bus

A pure electric passenger car and frame structure technology, applied in the field of pure electric passenger cars, can solve the problems that the mechanical structure of the body does not reach the optimal stable equilibrium state, the displacement of the chassis, and the upper and lower structures are not integrated, and achieve the reasonable layout of the bus and the center of gravity of the body. The effect of reducing and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

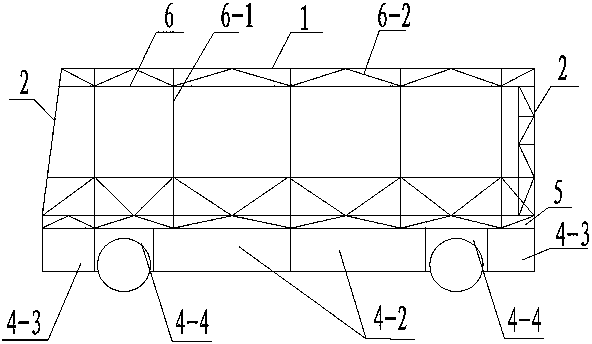

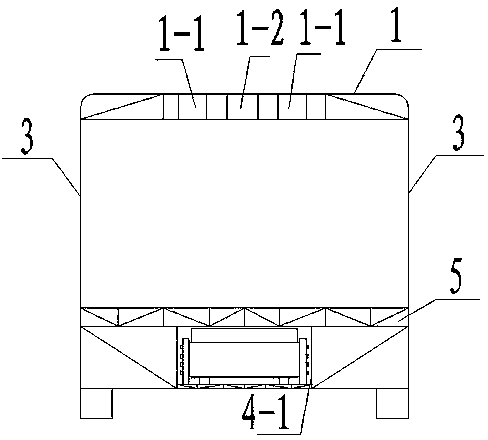

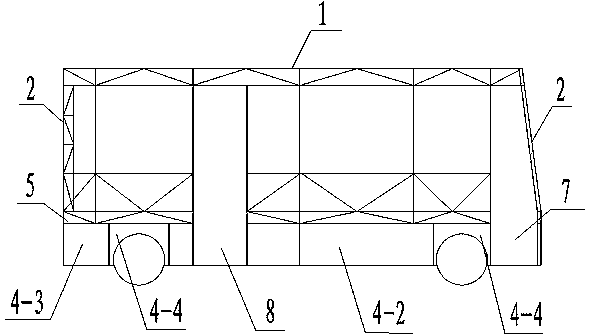

[0026] See attached figure 1 , 2 , 3, 4, 5, 6 and 7, a frame structure of a fully load-bearing pure electric bus, including a roof frame assembly 1, a front and rear frame assembly 2, a left and right side frame assembly 3, and a chassis frame assembly Assemblies, floor frame assemblies 5, each assembly is composed of truss structures, and the chassis frame assembly structure includes warehouse-type longitudinal beams 4-1 arranged at the center line of symmetry, and warehouse-type longitudinal beams 4-1 -1 warehouse-type attached beams 4-2 on both sides, warehouse-type auxiliary beams 4-3 arranged on both sides of the front and rear ends of the warehouse-type longitudinal beams 4-1, and the chassis frame assembly is limited by the suspension system 4-4 on the wheel axle. The setting of the warehouse-type longitudinal beam 4-1 in the chassis frame assembly realizes the support function of the overall central symmetrical beam of the bus, which can resist huge front and rear im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com