Liquid outlet easy to open

A liquid outlet and integrated technology, applied in the field of easy-to-open liquid outlets, can solve the problems of small-diameter liquid outlets lacking easy-to-open sealing parts, easy to break, etc., and achieves the effects of low production cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

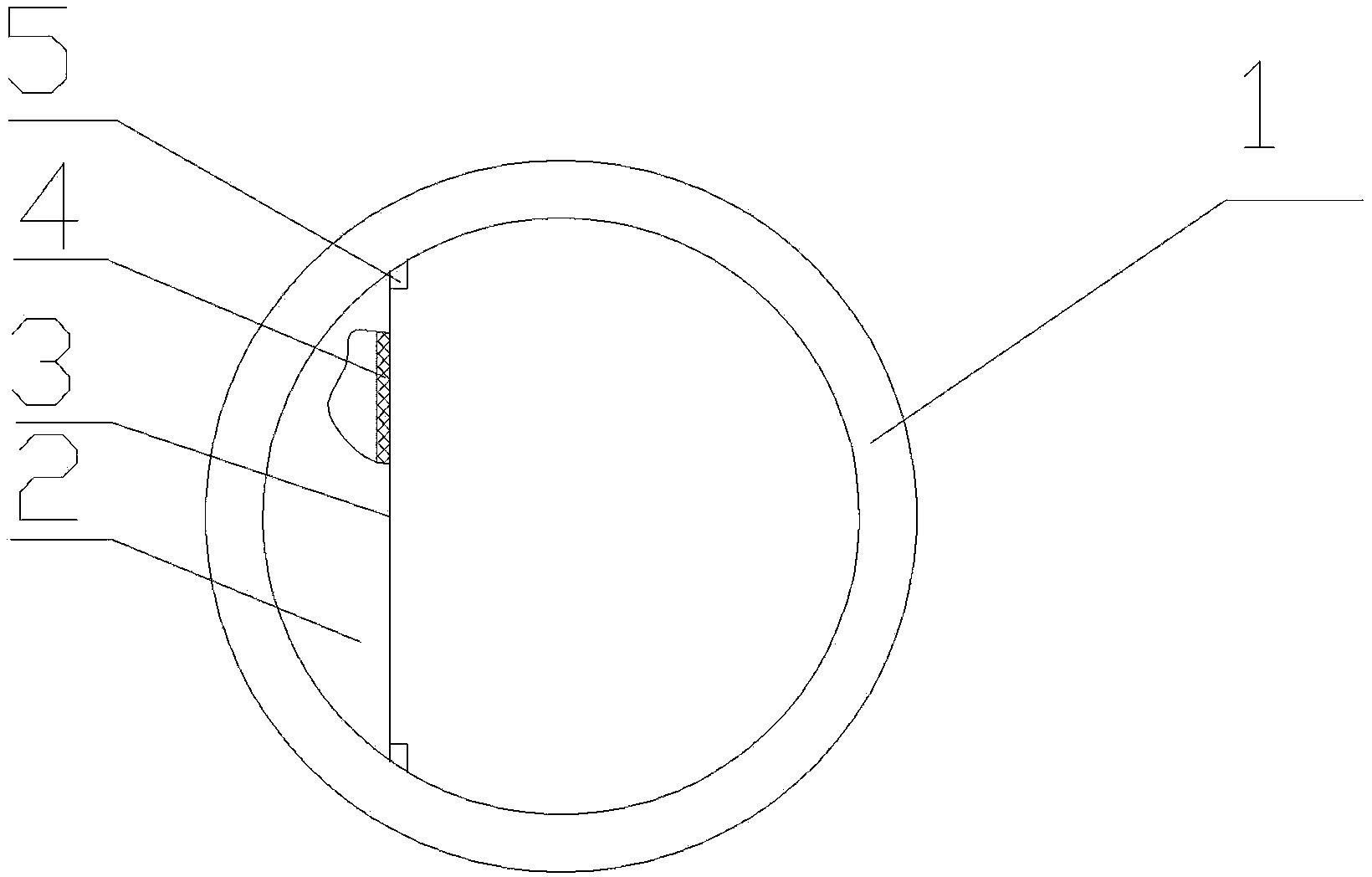

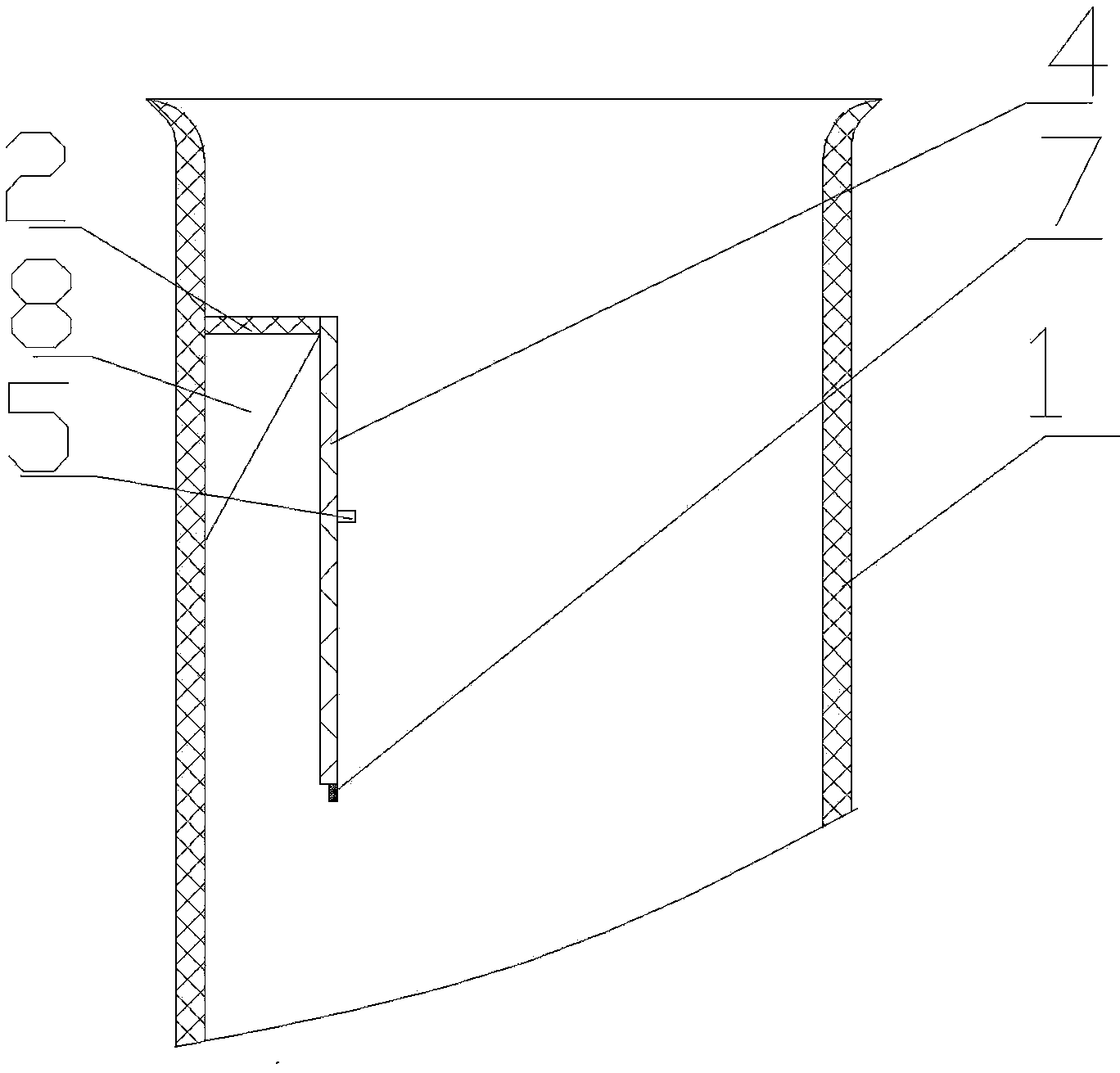

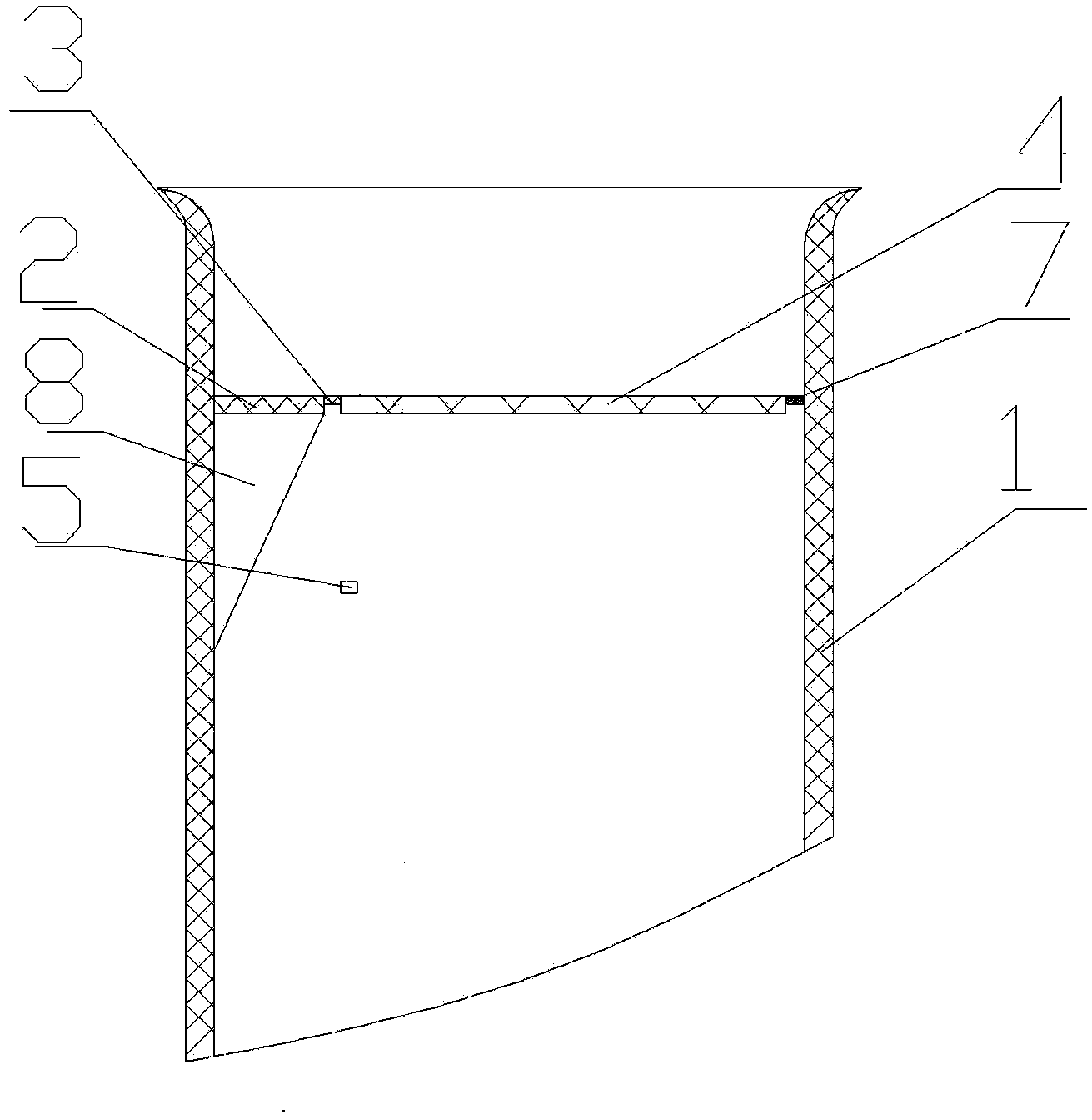

[0039] as attached Figure 1-4 As shown, an easy-to-open liquid outlet on the container cover includes a liquid outlet wall 1 and a sealing sheet arranged in the middle of the liquid outlet wall 1, and the sealing sheet includes a fixed sheet 2, a movable connection Part 3, easy-to-open sheet 4 and the easy-to-open connector 7 arranged on the edge of the easy-to-open sheet, the shape of the entire sealing sheet matches the internal shape of the liquid outlet, which is circular in the embodiment, and the fixed sheet 2 is made of A small semicircle composed of inferior arc and chord, the inferior arc is fixedly connected with the liquid outlet wall 1, the lower part of the fixed piece 2 is provided with a reinforcing rib 8 fixedly connected with the liquid outlet wall 1, and the chord of the fixed piece passes through the movable connector 3 Connected with the easy-open piece 4, the easy-open piece 4 is a large semicircle composed of a superior arc and a chord, and the superior ...

Embodiment 2

[0045] A container cover comprising an easy-to-open liquid outlet of the present invention, which includes a cover body 100, an upper cover 10 hinged with the cover body 100, a liquid outlet wall 1 is arranged inside the cover body 100, and the A sealing sheet is arranged in the liquid outlet wall 1, and the sealing sheet includes a fixed sheet 2, an easy-open sheet 4 connected with the fixed sheet 2, the fixed sheet 2 is fixedly connected with the liquid outlet wall 1, and the easy-to-open sheet 4 The opening piece 4 is fixedly connected with the liquid outlet wall 1, and the thickness of the connection part A11 formed between the easy-open piece 4 and the liquid outlet wall 1 is smaller than the connection formed between the fixed piece 2 and the liquid outlet wall 1 The thickness of the part B12, the thickness of the connection part C13 formed by the fixing piece 2 and the easy-open piece 4 is greater than the thickness of the connection part A11 formed by the easy-open piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com