Magnetic-solid magnetic liquid damper

A magnetic liquid and shock absorber technology, applied in the direction of springs/shock absorbers, magnetic springs, springs, etc., can solve the problems of limited energy dissipation, low effective energy consumption, complex structure, etc. Improved energy efficiency and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

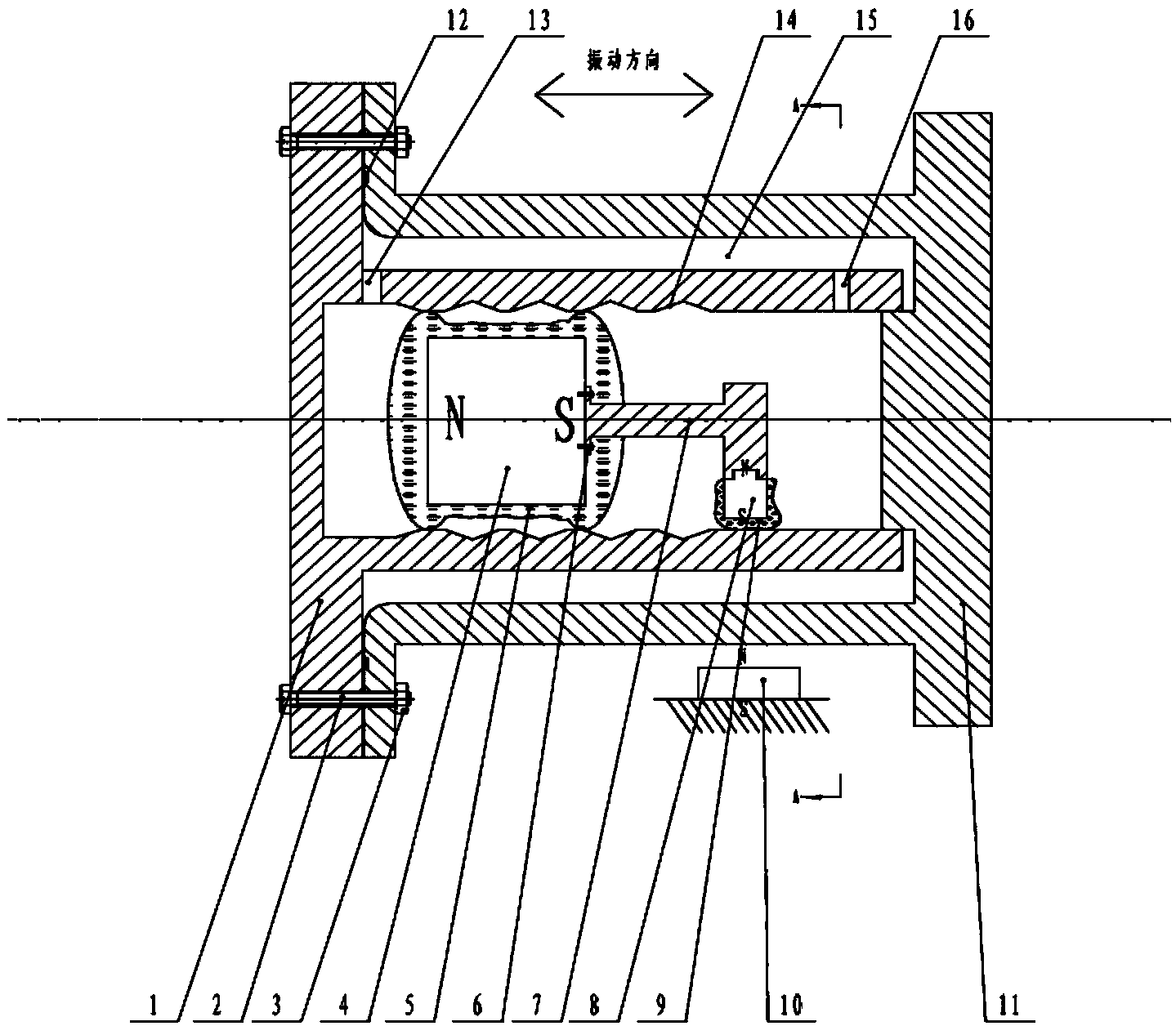

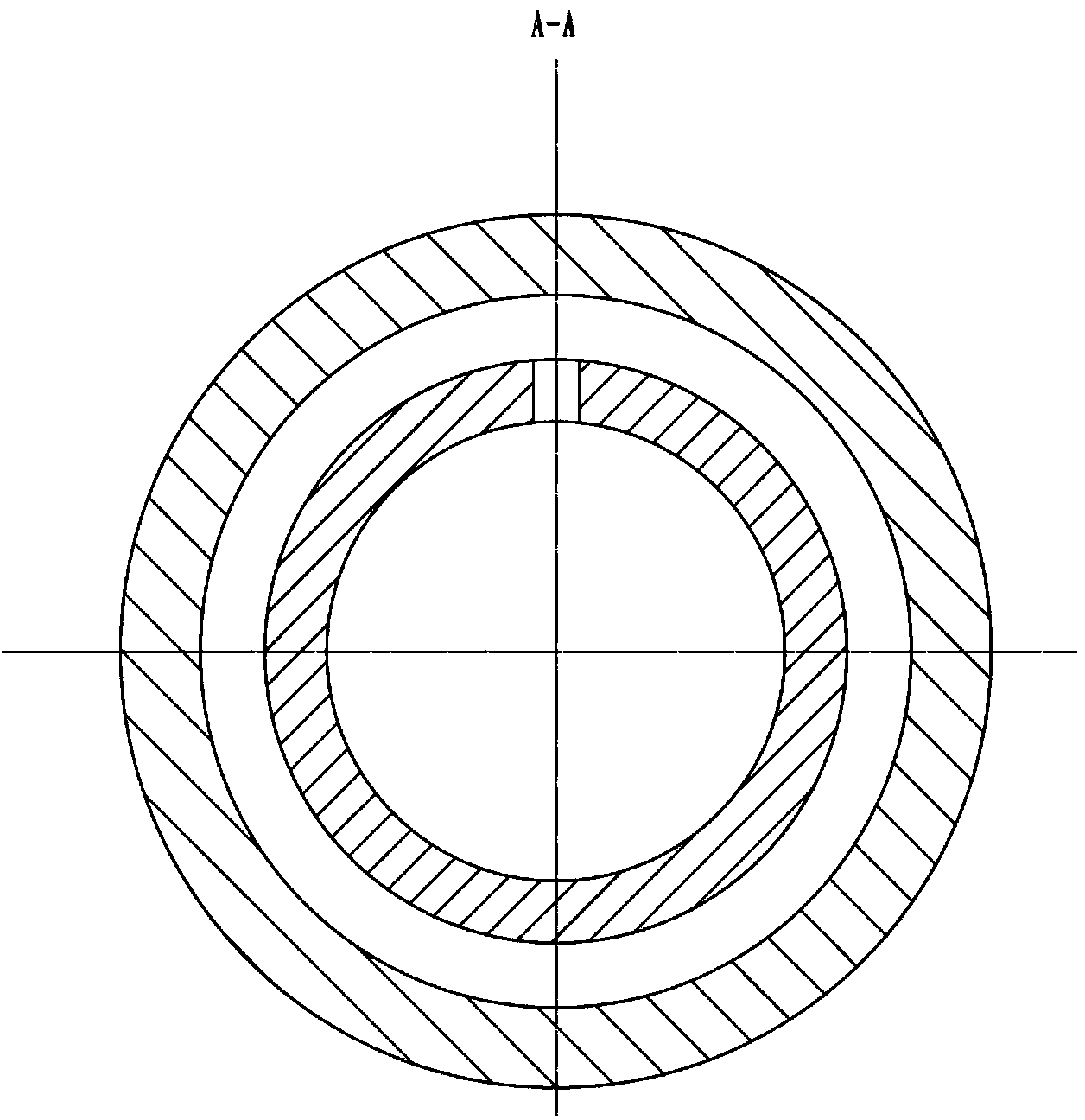

[0013] Utilize accompanying drawing to further illustrate the present invention:

[0014] The cylindrical permanent magnet (4) is rigidly connected to the internal permanent magnet sheet (8) by using a non-magnetically conductive right-angle connecting rod (7), adding magnetic liquid to the cylindrical permanent magnet (4) and the internal permanent magnetic sheet (8) in sequence, and Put the rigid body formed by connecting the cylindrical permanent magnet (4) and the internal permanent magnet sheet (8) into the non-magnetic shell (1), and seal the O-shaped rubber sealing ring through the bolt (2) and the nut (3). The non-magnetic shell (11) of (12) is rigidly connected with the non-magnetic shell (1). Utilize the mutual magnetic field force between the coaxial inner permanent magnet sheet (8) and the outer permanent magnet sheet (10), realize the non-distortion of the outer permanent magnet sheet (10) on the motion state of the inner permanent magnet (4) of the magnetic liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com