Wire harness fastening device

A wire harness and connector technology, which is used in the field of vehicle wire harnesses and wire harness fixing devices, can solve the problems of small application range, small contact area, and high matching accuracy requirements, achieve a wide range of applications and prevent bosses from rotating. , connection and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 A harness fastening device

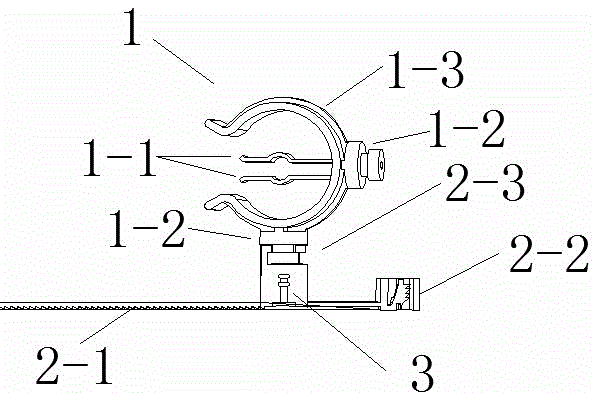

[0048] This embodiment includes a cable tie, a connector 2-3 for fixed connection with the cable tie, and an open C-shaped claw 1 that can be clamped on the outer periphery of the pipeline 4 for fixed connection with the connector 2-3.

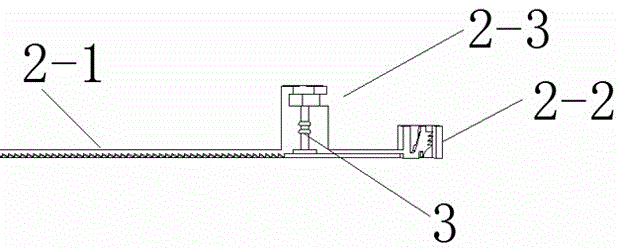

[0049] Such as figure 2 , Figure 4 As shown, the cable tie includes a belt body 2-1 and a lock tongue 2-2. The working surface of the belt body 2-1, that is, the front has barbs to ensure that the free end of the belt body 2-1 passes through the lock tongue in one direction. After 2-2, it can be locked without releasing.

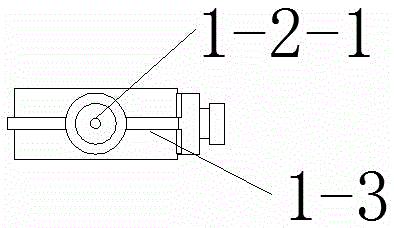

[0050] refer to figure 1 and image 3 , The outer peripheral surface of the claw 1 is provided with an I-shaped cylindrical structure boss 1-2 protruding in the radial direction, and the boss 1-2 is a coupling point between the claw 1 and the connecting piece 2-3. A plurality of bosses 1-2 are arranged at intervals along the circumferential direction on the outer periphe...

Embodiment 2

[0055] Example 2 A harness fastening device

[0056] The difference between this embodiment and embodiment 1 only lies in:

[0057] The main body of the claw is an open ellipse;

[0058] The outer peripheral surface of the claw is provided with a plurality of boss fixing points spaced apart along the extending direction of the outer peripheral surface. The boss is a prefabricated structure, which can be fixed on the boss by welding, riveting, threaded connection, etc. according to the required angle. fixedly connected to the jaws. This connection method determines the number of bosses and installation angles according to the actual situation during assembly, which can avoid waste of components, reduce the weight of components, reduce the volume of components, and avoid interference with surrounding components.

Embodiment 3

[0059] Example 3 A harness fastening device

[0060] The difference between this embodiment and Embodiment 1 is that: the main body of the claw is an open ellipse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com