LED substrate for LED light bar and LED light bar with large light emitting angle

A technology of LED strips and LED substrates, which is applied in the direction of semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, which can solve problems such as poor ductility and toughness, poor heat dissipation performance, and complicated processes, and achieve the effect of reducing restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

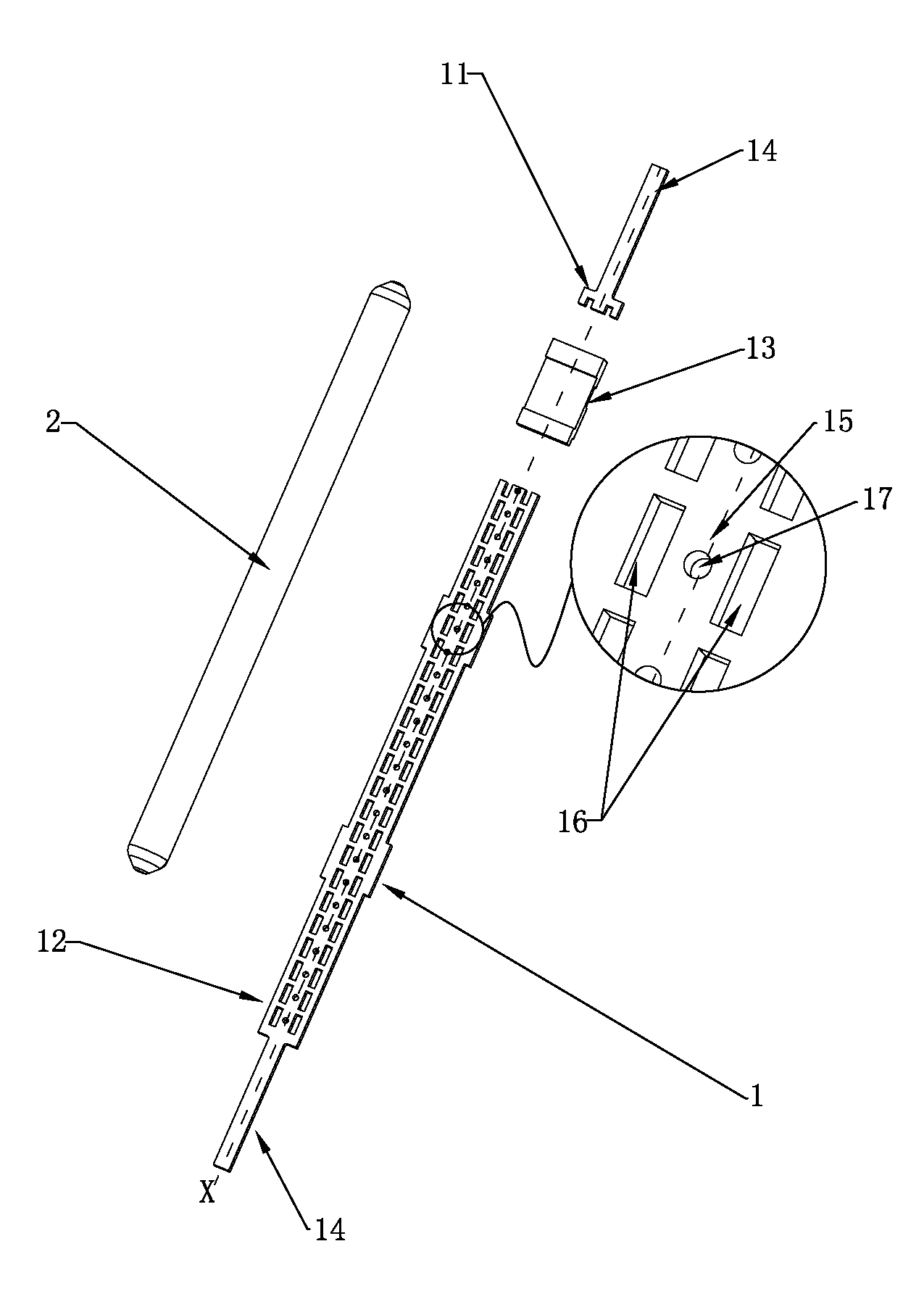

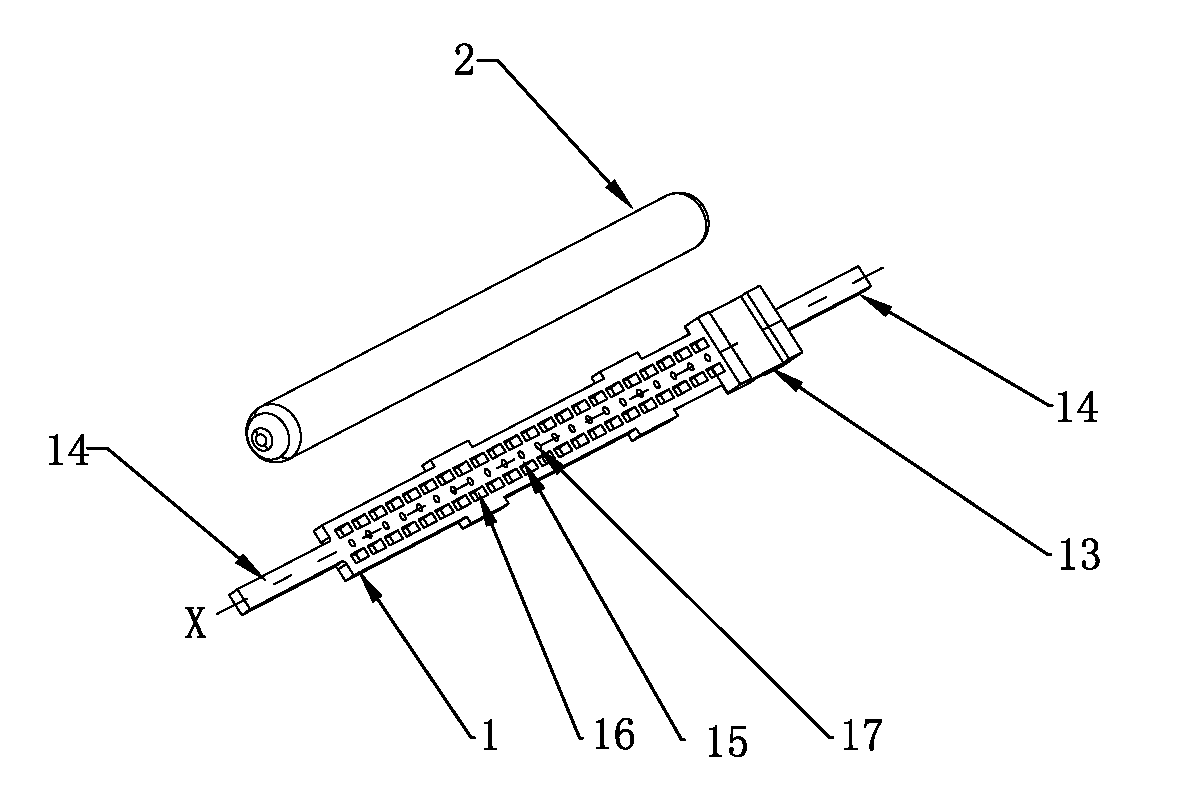

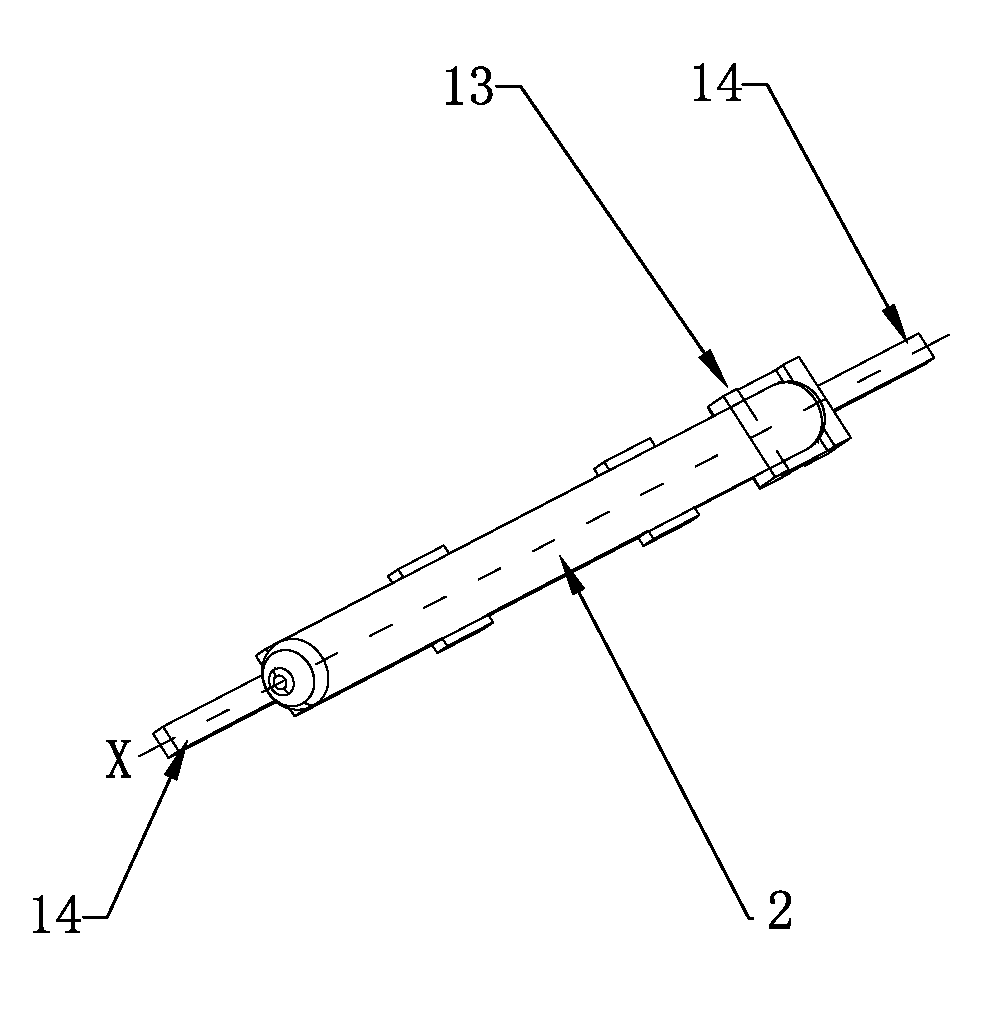

[0026] One of the specific implementation modes of the present application, such as Figure 1 to Figure 4 As shown, this embodiment takes a wick tube product used to form an LED wick column (see background art) as an example, which is composed of an LED substrate 1 , an LED crystal 3 , a fixing glue 4 and a fluorescent tube 2 .

[0027] The LED substrate 1 is in the shape of a strip, including a positive electrode copper sheet 11, a negative electrode copper sheet 12 and an insulating block 13. The positive electrode copper sheet 11 and the negative electrode copper sheet 12 are connected to the insulating block 13 respectively, so that the positive electrode copper sheet 11 and the negative electrode copper sheet 12 Structurally connected but electrically insulated, that is, the positive copper sheet 11 and the negative electrode copper sheet 12 are equivalent to the first electrode and the second electrode of the LED substrate 1 . Both the positive copper sheet 11 and the ne...

Embodiment 2

[0036] In the second embodiment of the present application, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 lies in that the crystal-bonding sites 15 on the front side and the crystal-bonding sites 15 on the back side of the crystal-bonding area are arranged in dislocation. In other words, odd-numbered crystal-bonding positions 15 such as 1, 3, and 5 fix the LED crystal 3 on the front of the LED substrate 1, and even-numbered crystal-bonding positions 15 such as 2, 4, and 8 fix the LED crystal 3 on the LED substrate 1. the opposite of . In this way, the purpose of more uniform light emission on both sides of the LED substrate 1 can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com