Shield segment joint anti-penetrability performance test device

A technology of shield segment and test device, which is applied in the direction of using liquid/vacuum to measure liquid tightness and detecting the appearance of fluid at the leakage point, etc., which can solve the problem of lack of test devices and achieve simple operation and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

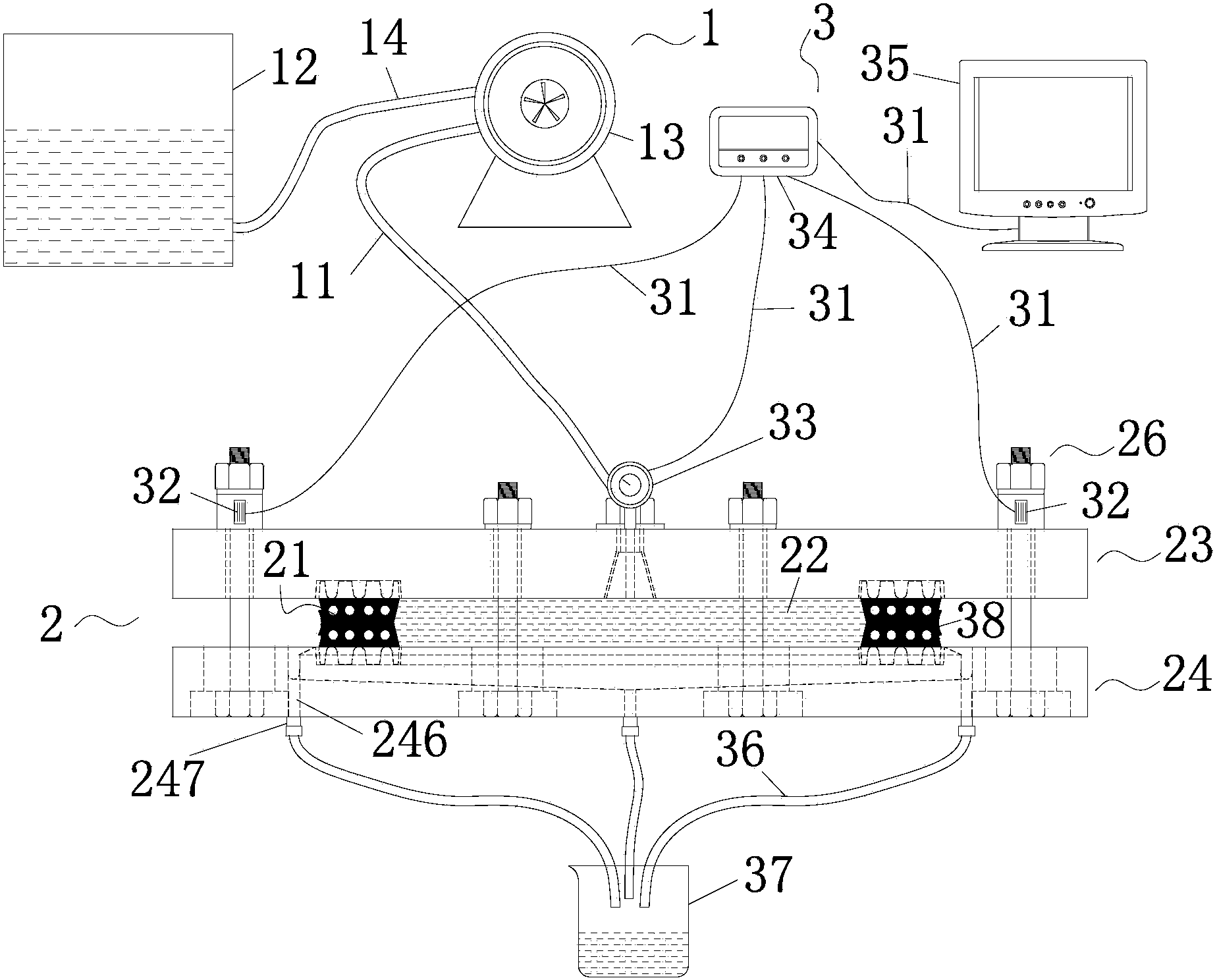

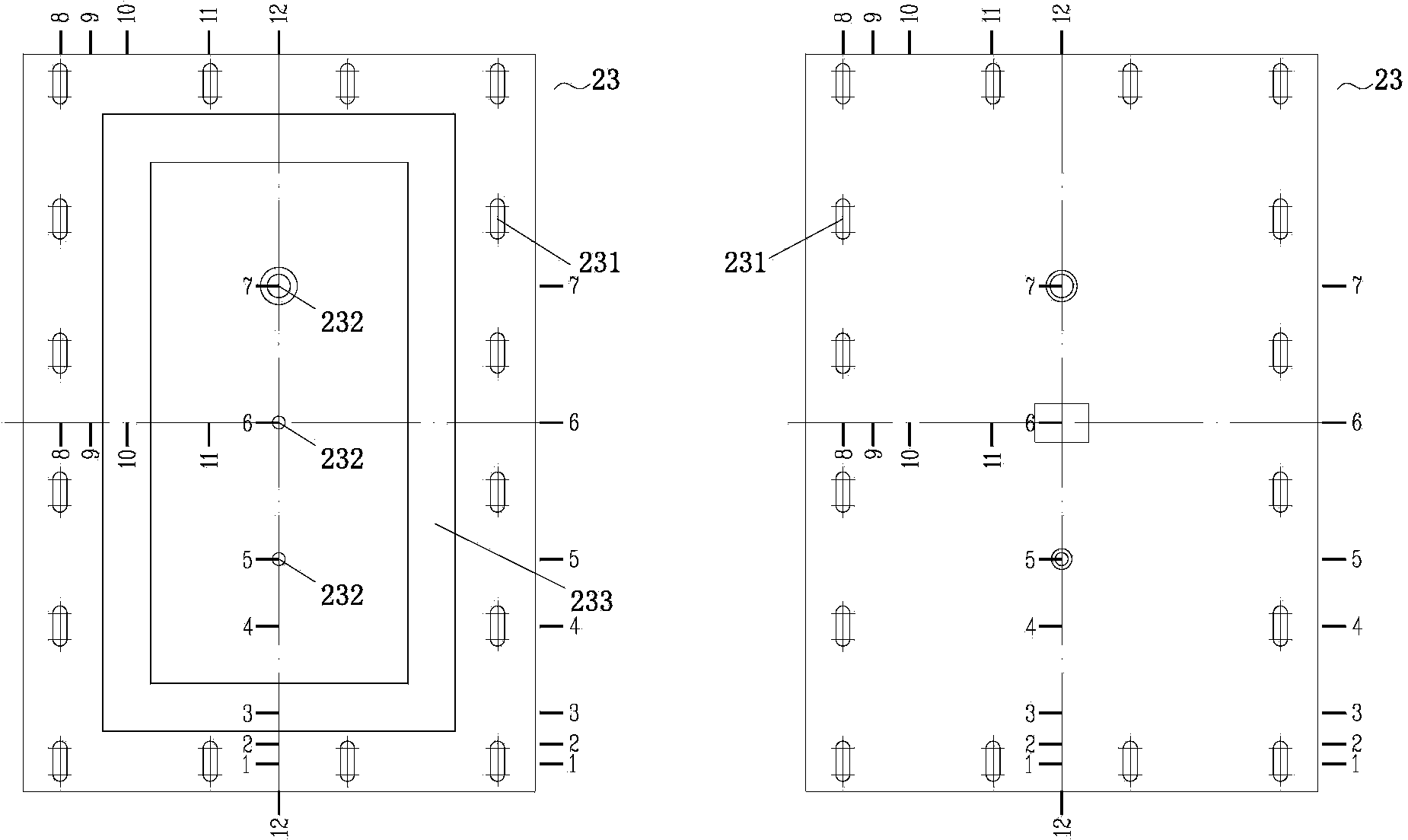

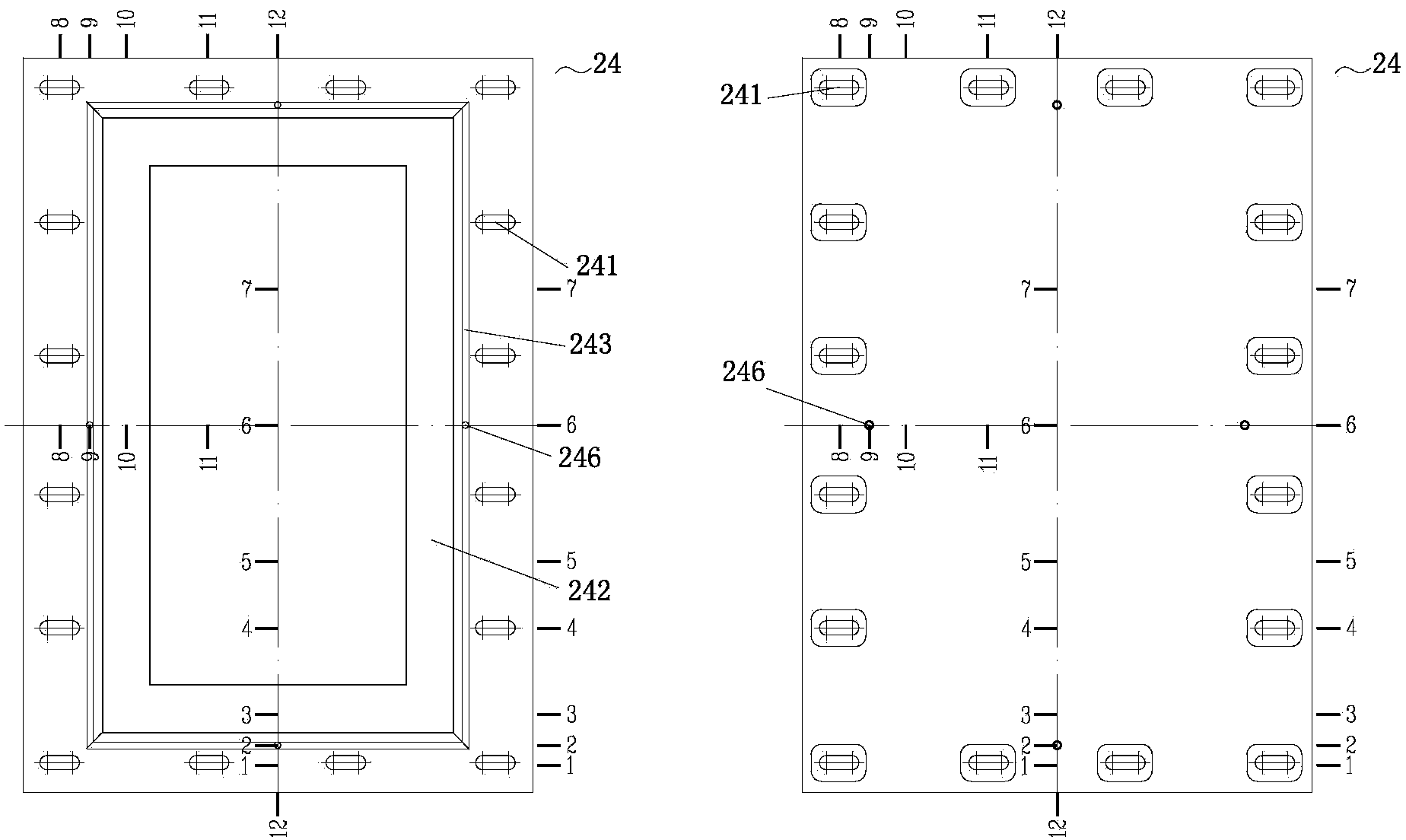

[0047] like figure 1 As shown, the shield segment joint anti-seepage performance test device of the present invention includes: a high-pressure water supply system 1 for providing test pressure water 22; a test bench 2 for installing a test piece 21, providing a pressure water 22 action space and Realize the simulation of the contact state of the segment joint; the measurement system 3 is used to set the test working condition parameters and measure the test process data; the pressurization system 1 and the test bench 2 are connected by a high pressure resistant hose 11; the quantity The measuring system connects the strain sensor 32 and the pressure sensor 33 installed on the test bench 2 with the recorder 34 and the computer 35 through cables 31 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com