Non-contact electricity verification device based on vertical field intensity difference distribution curve matching

A distribution curve, non-contact technology, applied in the direction of using digital measurement technology for measurement, can solve the problems of complicated operation process, reference value and alarm threshold value susceptible to external interference, low accuracy, etc., to avoid complex and changeable , Avoid multiple measurements and improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

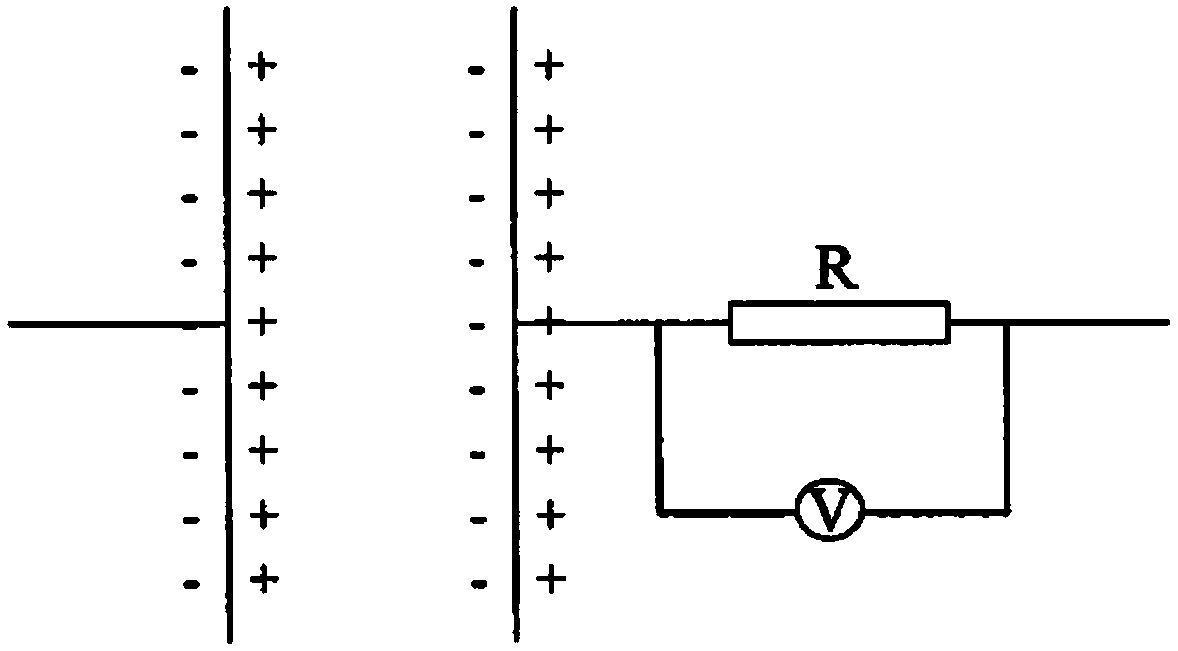

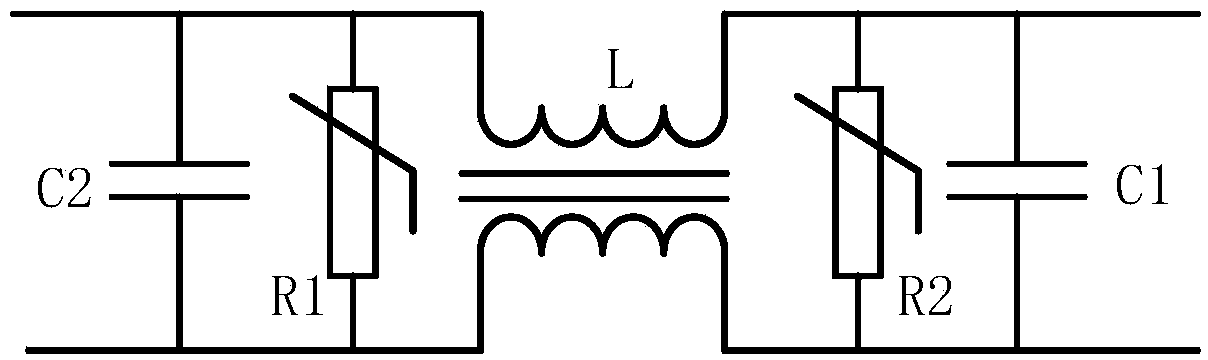

[0026] Such as figure 1 As shown, the non-contact electrometry device of the embodiment of the present invention includes a signal acquisition unit 1, a signal transmission unit 2 and a data analysis unit 3. The signal acquisition unit 1 collects the voltage signal on the high-voltage electrified body, and transmits it to the The data analysis unit 3 is used to analyze the signal data by the data analysis unit 3, so as to determine whether the charged body is charged.

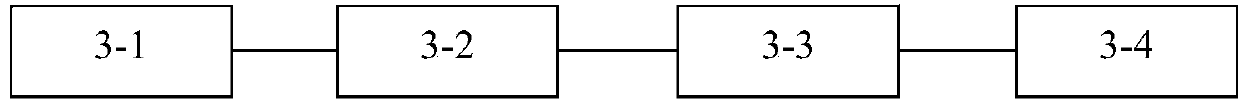

[0027] The signal acquisition unit 1 of the non-contact electroscope is composed of a sensing module 1-1, a filter module 1-2, an acquisition module 1-3 and an acquisition control module 1-4 connected in sequence. When the signal acquisition unit 1 is working, the sensing module 1-1 collects the voltage signal of the high-voltage electrified body, after being low-pass filtered by the filter module 1-2, it is sent to the acquisition module 1-3 for analog-to-digital conversion into a digital signal, which is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com