Servo electric cylinder controller parameter setting method based on experiments

A servo electric cylinder, parameter setting technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of complex parameter setting and large performance difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific steps of an experiment-based servo electric cylinder controller parameter setting method are as follows:

[0055] The first step is to build a servo electric cylinder control system

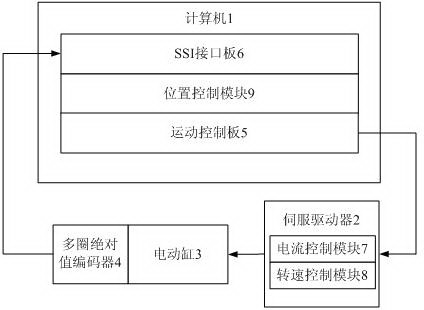

[0056] Servo electric cylinder control system, including: computer 1, servo drive 2, electric cylinder 3, multi-turn absolute position sensor 4, motion control board 5, SSI interface board 6, current control module 7, speed control module 8 and position control module 9 .

[0057] The motion control board 5 and the SSI interface board 6 are installed in the computer 1, the output end of the motion control board 5 is connected to the input end of the servo drive 2, the output end of the servo drive 2 is connected to the input end of the electric cylinder 3, and the multi-turn absolute position The sensor 4 is coaxially connected with the lead screw of the electric cylinder 3 , and the output end of the multi-turn absolute position sensor 4 is connected with the input end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com