Voltage source type direct-current deicing and static synchronous compensation device and control method thereof

A static synchronous compensation, DC ice melting technology, applied in the installation of cables, reactive power adjustment/elimination/compensation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

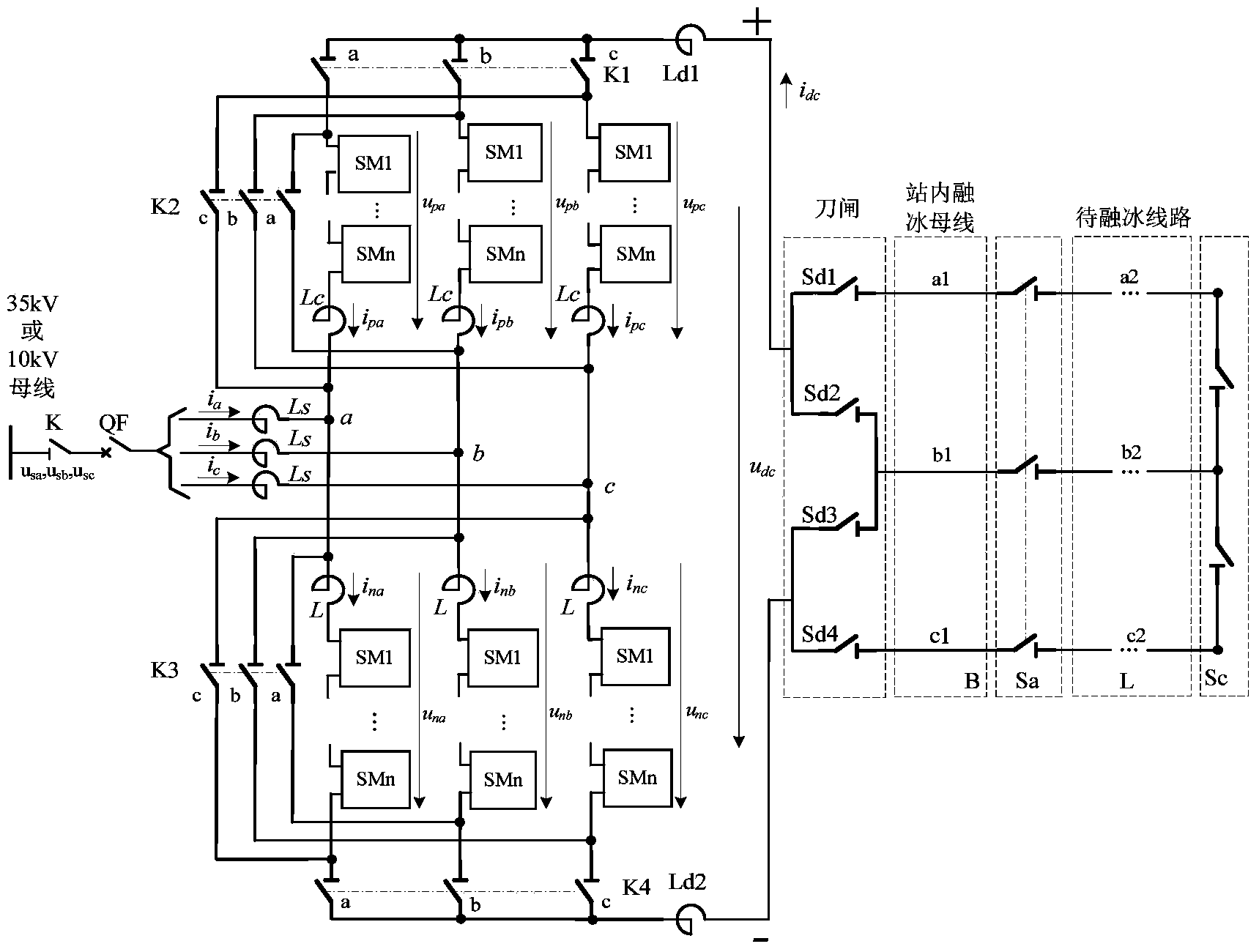

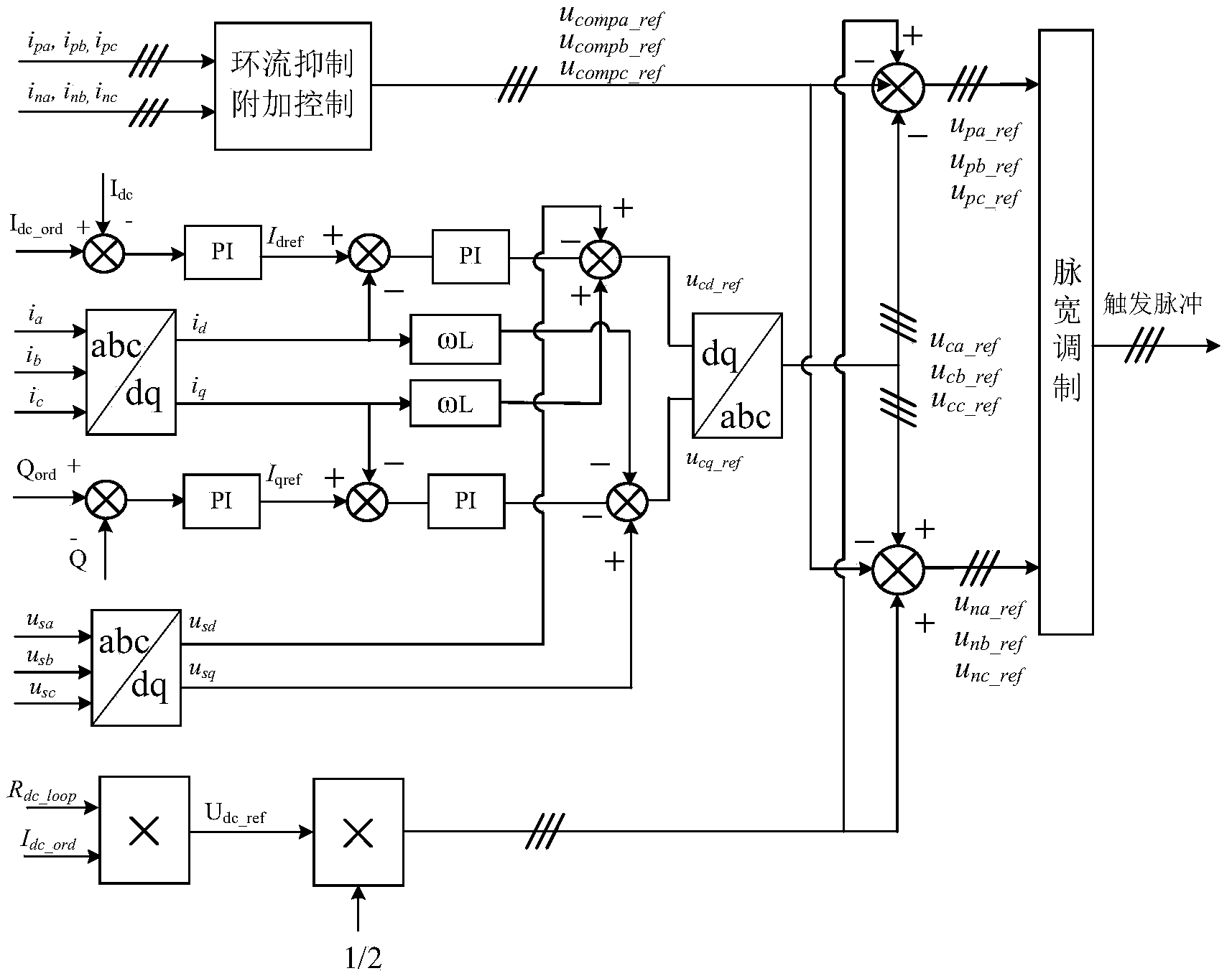

[0059] The structural diagram of the voltage source type DC ice melting and static synchronous compensation device of the present invention is as follows figure 1 As shown, the voltage source type DC ice-melting and static synchronous compensation device of the present invention includes at least one basic commutation unit, the basic commutation unit includes an isolation switch K, a circuit breaker QF, and a connecting reactor Ls. The modular multilevel converter MMC of the bridge sub-module, the knife gates K1, K2, K3, K4, smoothing reactors Ld1, Ld2; among them, the modular multilevel converter MMC, the connecting reactor Ls and the knife gate K1, K2, K3, and K4 all include three phases a, b, and c, and the three-phase structures are exactly the same; one end connected to the reactor Ls is connected to the AC side bus through the isolation switch K and the circuit breaker QF, and the other end It is connected to the corresponding phases of the AC input terminals of the modu...

Embodiment 2

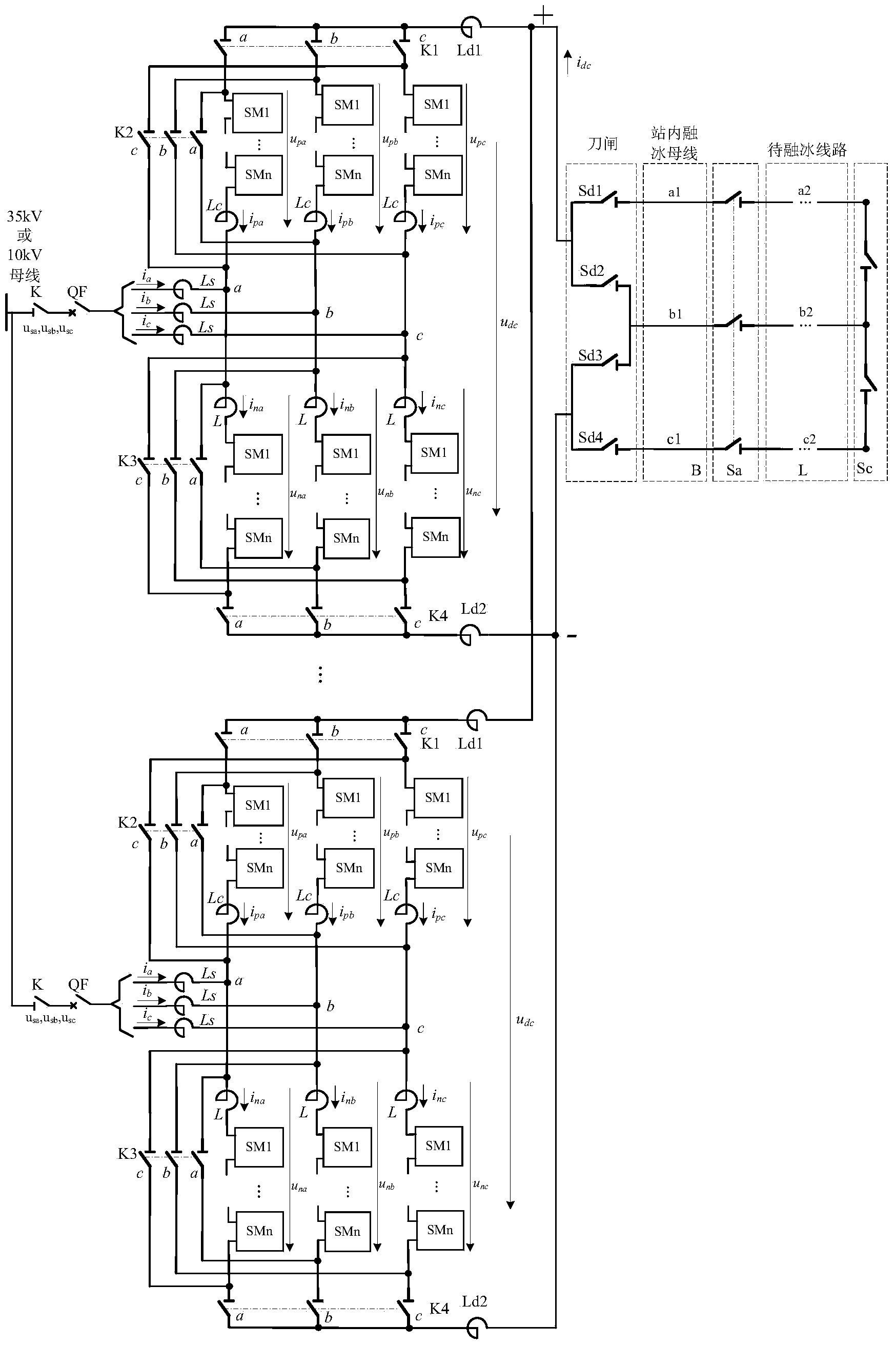

[0100] The structural diagram of the voltage source type DC ice melting and static synchronous compensation device of the present invention is as follows figure 2 As shown, there are M basic converter units, where M is a positive integer; one end of the smoothing reactor Ld1 of the M basic converter units is connected together, and one end of the smoothing reactor Ld2 of the M basic converter units connected together, one end of the switch Sd1, Sd2 is connected to the other end of the smoothing reactor Ld1 of the M basic converter units, and one end of the switch Sd3, Sd4 is connected to the smoothing reactor Ld1 of the M basic converter units. The other end of the reactor Ld2 is connected, the other end of the knife switch Sd1 is connected to one end of the a1 phase of the ice-melting bus B in the station, and the other end of the knife switch Sd2 and Sd3 is connected to one end of the b1 phase of the ice-melting bus B in the station. The other end of the knife switch Sd4 is...

Embodiment 3

[0104] The structure of the voltage source type DC ice-melting and static synchronous compensation device of the present invention is the same as that of embodiment 1 or embodiment 2, wherein the full-bridge sub-module in the modular multi-level converter MMC adopts a single fully-controlled device Full-bridge sub-module, the structural diagram of the full-bridge sub-module using a single full-control device is shown in Figure 5 As shown, it includes four fully controlled devices S1, S2, S3, S4, four diodes D1, D2, D3, D4, a capacitor C, a thyristor SCR, a fast switch Ks, fully controlled device S1 and diode D1 Anti-parallel connection, fully-controlled device S2 is connected in reverse parallel with diode D2, fully-controlled device S3 is connected in reverse parallel with diode D3, fully-controlled device S4 is connected in reverse parallel with diode D4, that is, the positive terminal of the fully-controlled device is connected to the diode negative The negative terminal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com