System and method for online inspection of turbines including aspheric lens

An aspheric lens, spherical lens technology, applied in the camera body, TV system components, telescopes and other directions, can solve the problem of difficult to keep the lens alignment, damage to the effective service life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

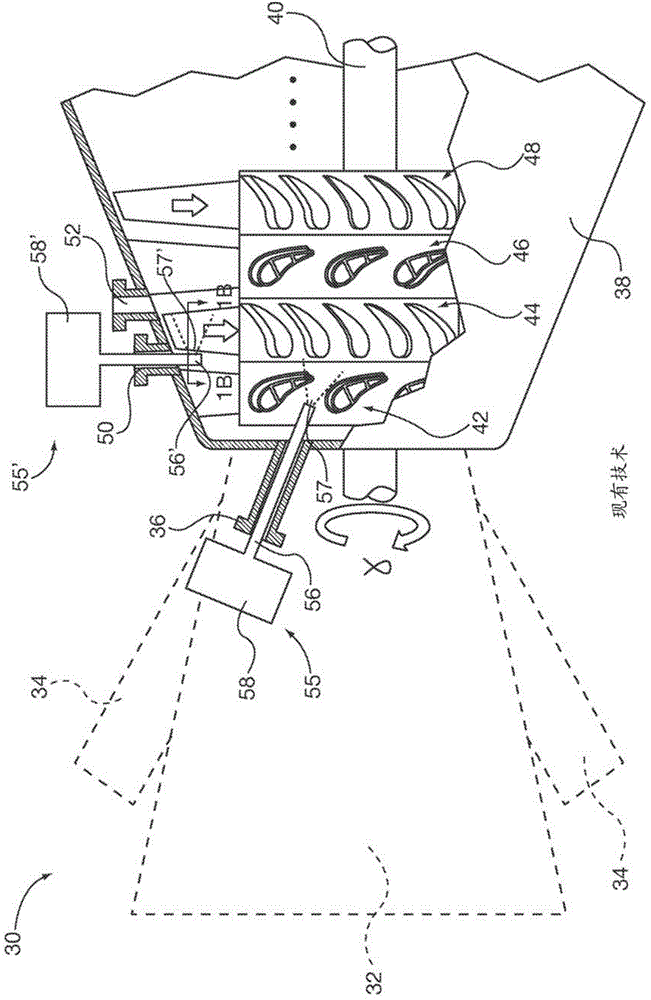

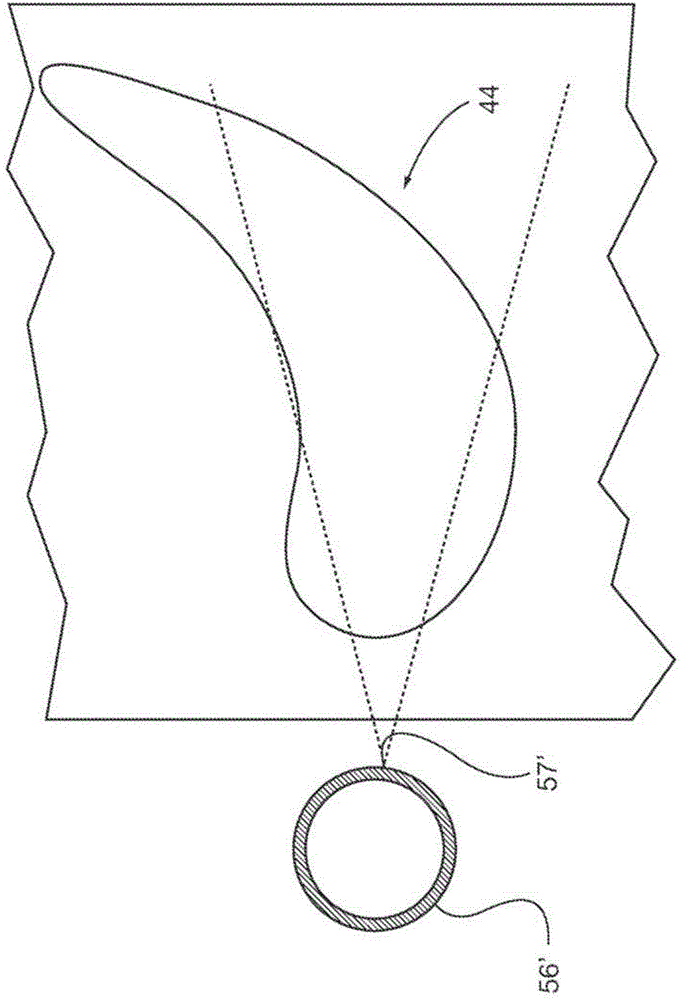

[0044] After considering the following description, it will be apparent to those skilled in the art that the teachings of the present invention can be readily utilized in an optical camera system operating on-line for non-destructive internal inspection of power generating turbines, including gas turbine combustors and turbines segment, which is at high operating temperatures in the range of over 600°C (1112°F) and includes combustion gas pollutants. The detection system includes one or more aspheric lenses capable of withstanding continuous operating temperatures above 600°C. Aspheric lenses alone or in combination with spherical lenses create a wider field of view and require fewer combined lenses than lens mounts that include only spherical lenses. A cooling system included in the detection system facilitates continuous operation and inhibits fouling of the outer surface of the lens by combustion gases.

[0045] Aspherical Lens Optical System

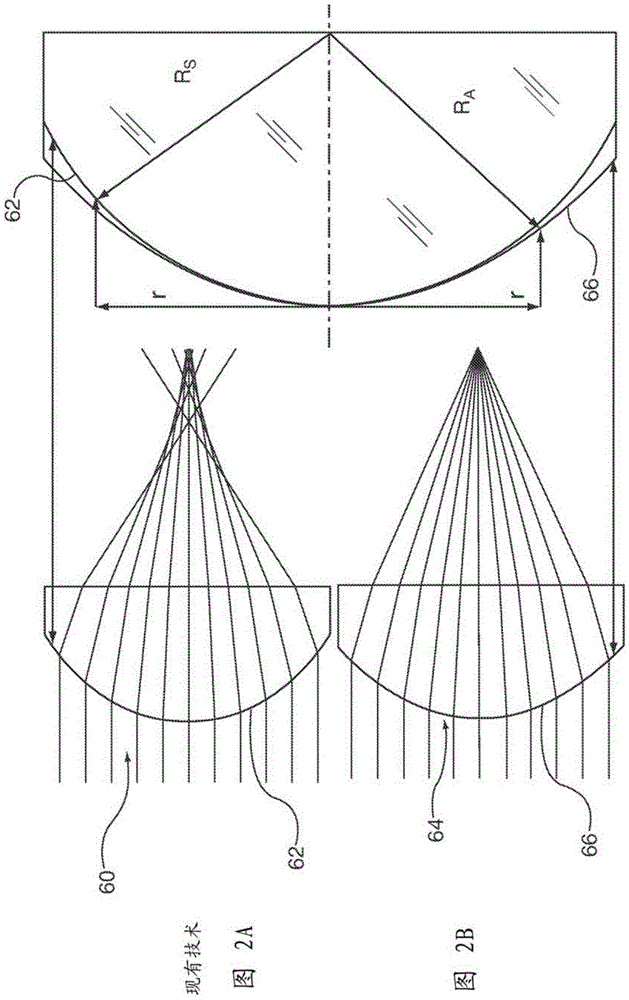

[0046] To improve the mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com